Method for measuring equivalent salt deposit density of high-voltage insulator

A high-voltage insulator, equivalent salt density technology, applied in the direction of material resistance, etc., can solve the problem of not being able to contaminate the description of equivalent salt density value, and unable to describe the contamination law on the surface of strong hydrophobic insulators well, to avoid errors and improve. The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below with reference to the drawings and embodiments. It can be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

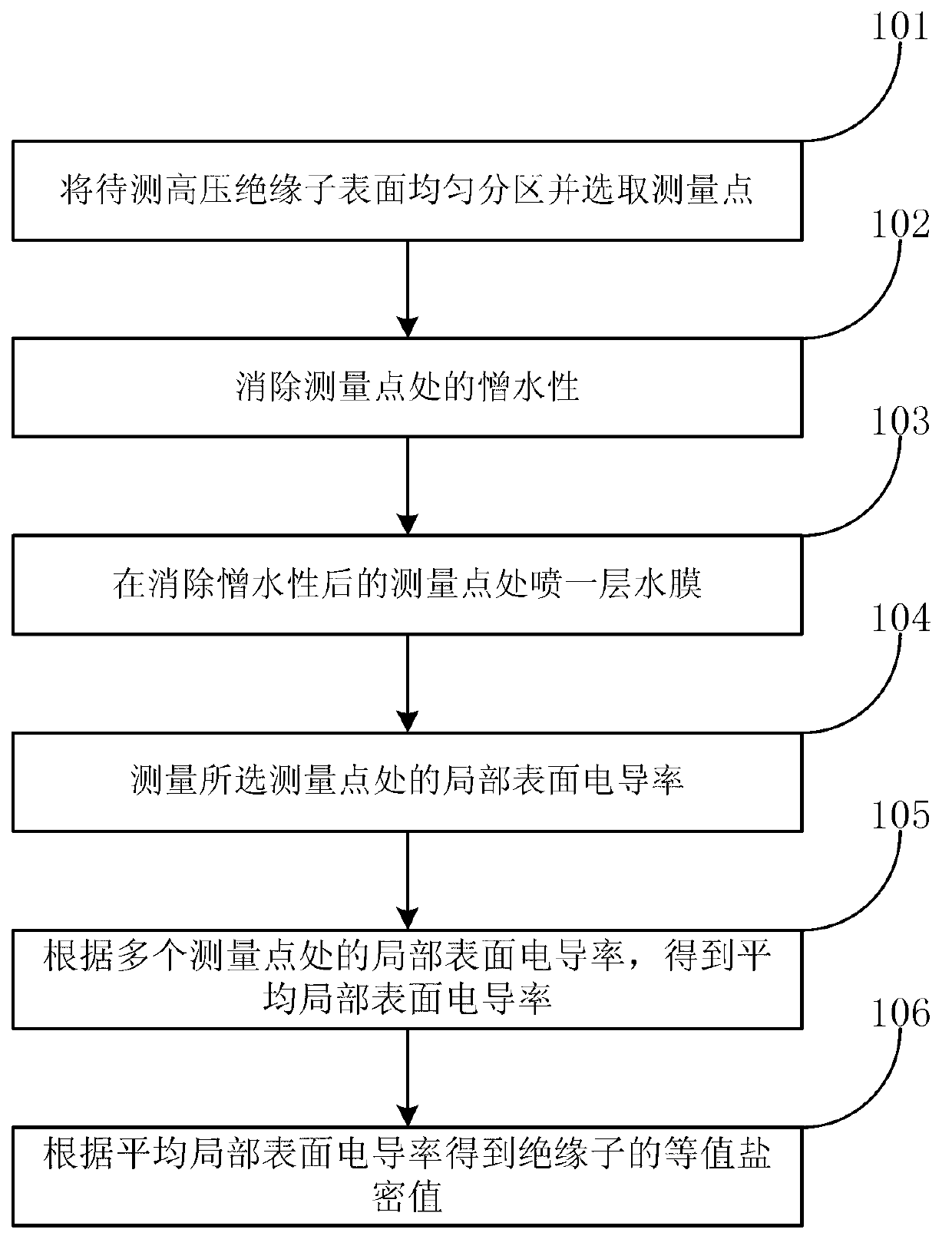

[0043] figure 1 It is a flowchart of a method for measuring equivalent salt density of high-voltage insulators according to an embodiment of the present invention. The method includes:

[0044] Step 101: Evenly divide the surface of the high-voltage insulator to be tested into multiple regions, and in each region, randomly select one location as a measurement point.

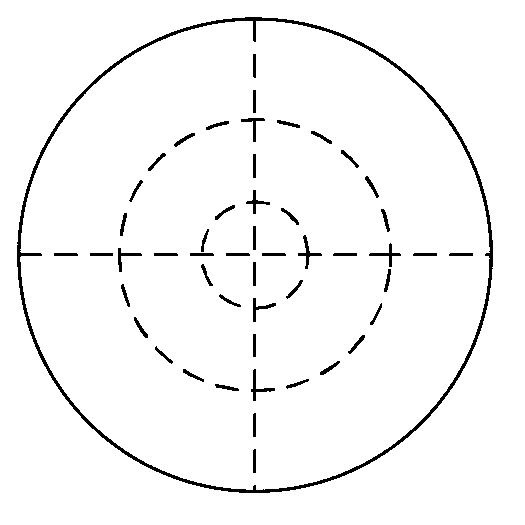

[0045] The insulator includes multiple sheds. For each shed, the partition method of four zones and three rings is adopted. figure 2 It is a schematic diagram of the partitioning of each shed of the insulator provided by the embodiment of the present invention. As shown in the figure, one shed of the high-voltage insulator to be tested is partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com