Rubber suspension for automobile engine

An automobile engine and rubber technology, applied in the direction of springs, etc., can solve the problems of easy aging of rubber mounts, easy friction and heat generation, uneven deformation, etc., and achieve the effects of avoiding oil pollution, preventing rubber aging, and enhancing work performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

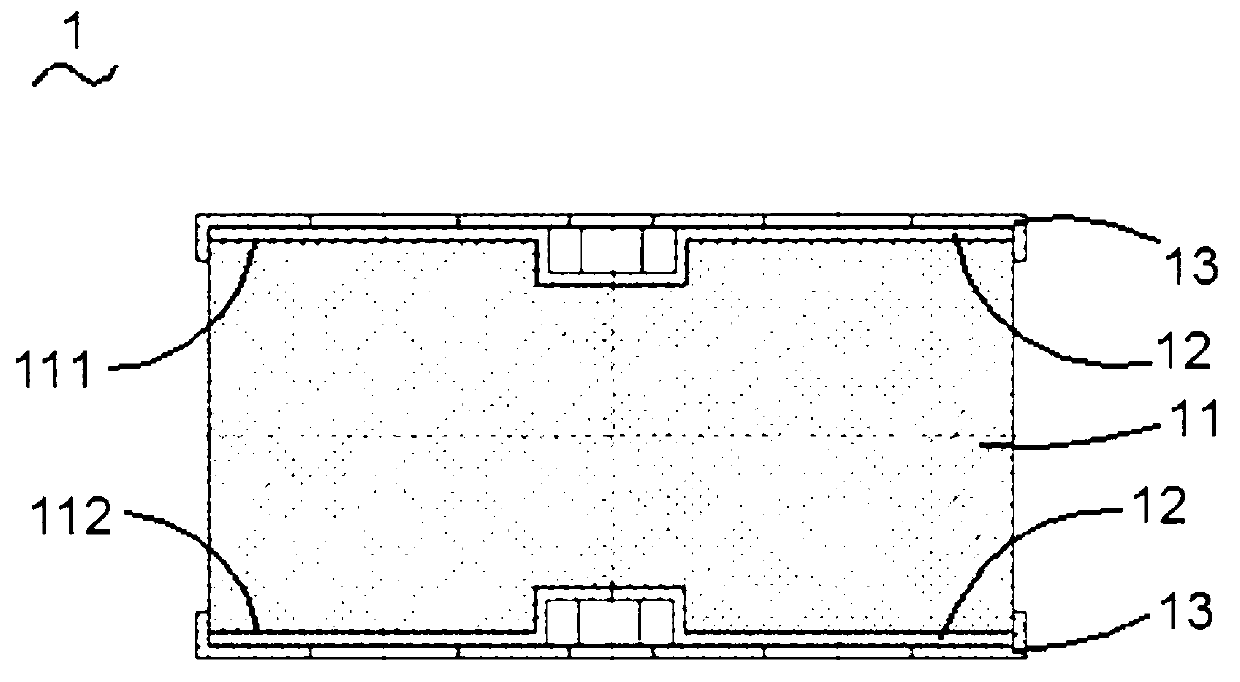

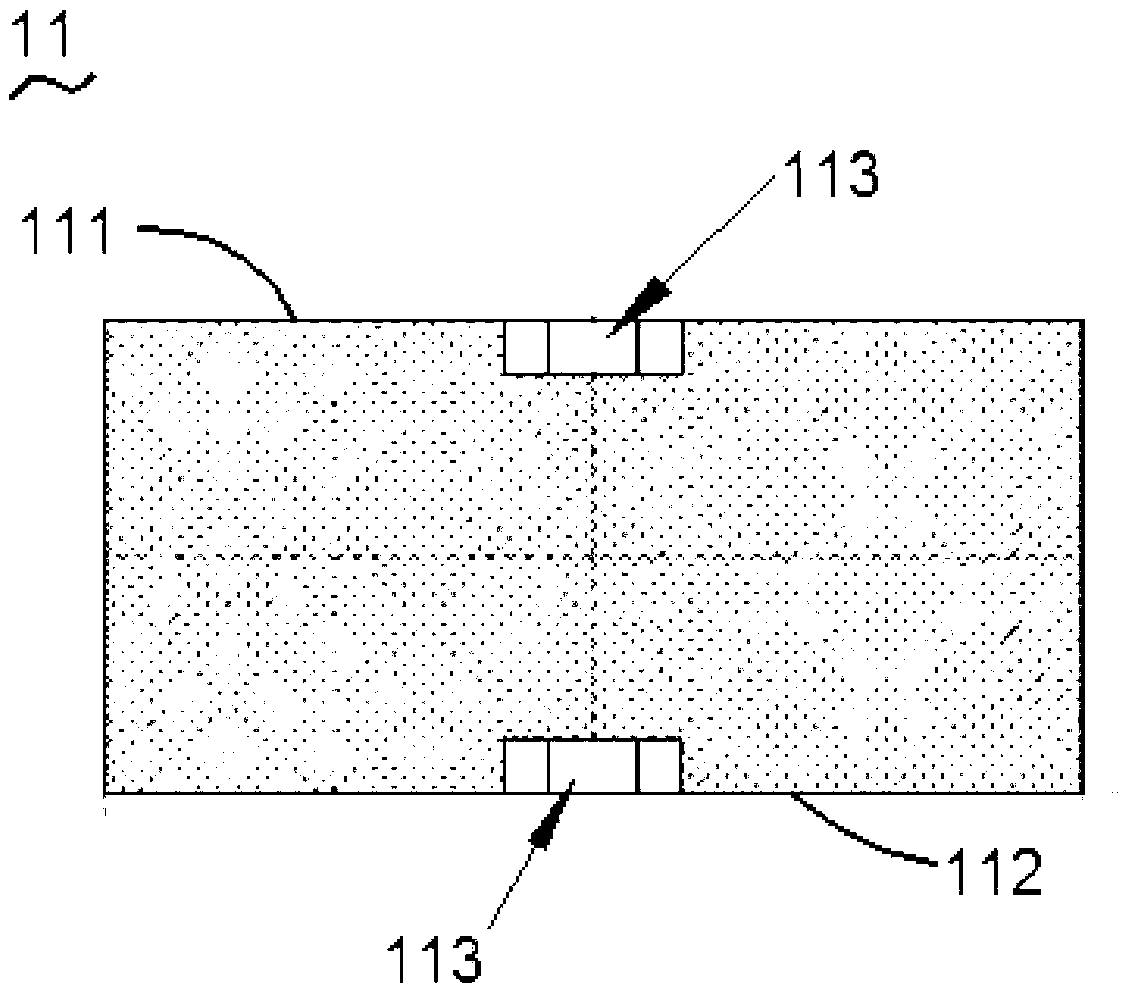

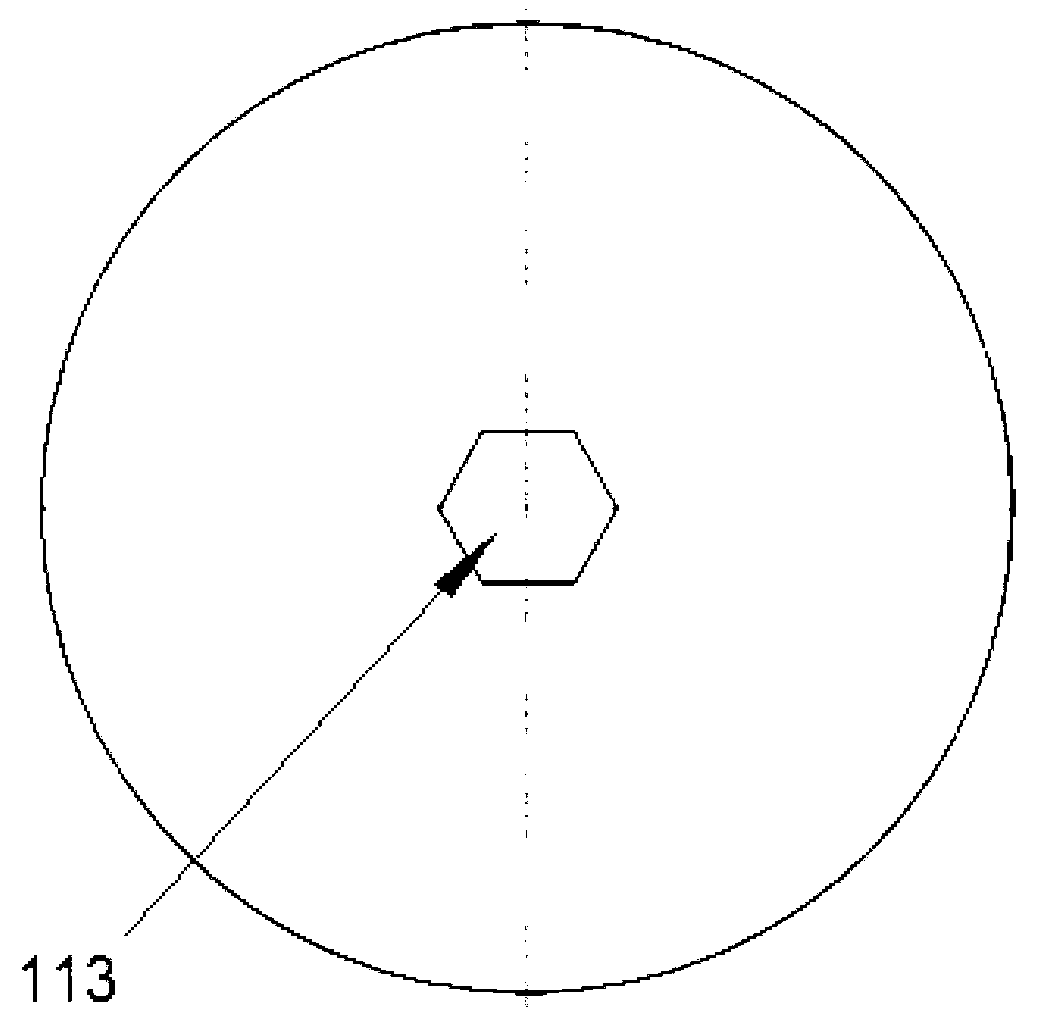

[0023] see figure 1 , figure 1 Shown is the assembly diagram of the automobile engine rubber mount of the present invention. The automobile engine rubber mount 1 includes a rubber part 11, the rubber part 11 has a cylindrical structure, and the middle part of the first cylindrical surface 111 and the middle part of the second cylindrical surface 112 of the rubber part 11 are respectively provided with a corresponding container. A hole 113; a positioning plate 12, the positioning plate 12 is respectively arranged on the first cylindrical surface 111 and the second cylindrical surface 112 of the rubber member 11; and a fixed plate 13, the fixed plate 13 is respectively arranged on the corresponding The side of the positioning plate 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com