Unmanned aerial vehicle low impact catapult pneumatic and hydraulic system

A kind of ejection device, pneumatic hydraulic technology, applied in the direction of launch/drag transmission device, fluid pressure actuation device, mechanical equipment, etc., can solve the problems of difficult processing, large impact at the start-up stage, complex process, etc., and achieve high reliability and low impact Ejection, overcoming the effect of large impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

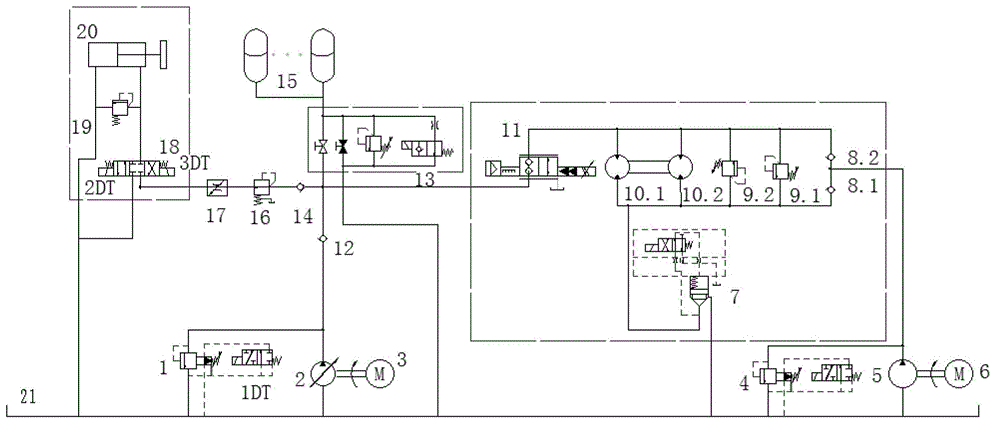

[0021] A gas-hydraulic system of a UAV low-impact ejection device, such as figure 1 As shown, it is composed of main oil pump electromagnetic unloading overflow valve 1, main oil pump 2, main oil pump motor 3, charging pump electromagnetic unloading overflow valve 4, charging pump 5, charging pump motor 6, cartridge valve 7, second A one-way valve 8 and its safety valve 9, hydraulic motor 10, electro-hydraulic proportional cartridge valve 11, second one-way valve 12, safety and shut-off valve block 13, third one-way valve 14, accumulator 15, reducing Pressure valve 16, speed control valve 17, electromagnetic reversing valve 18, proportional overflow valve 19, deceleration hydraulic cylinder 20, oil tank 21 and oil pipes connected between each original; the main oil pump motor 3 drives the main oil pump 2, the main oil pump 2. The oil suction po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com