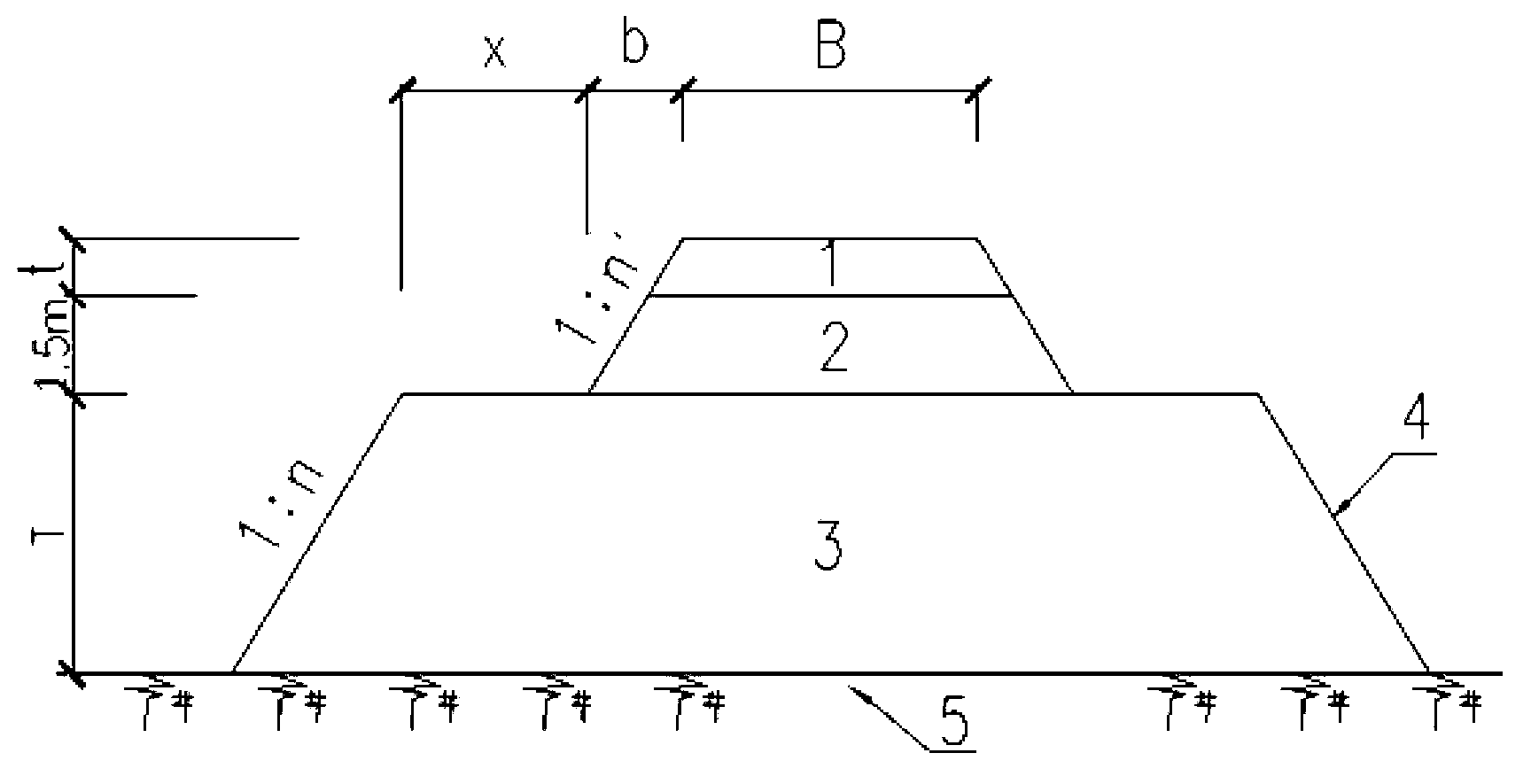

Method for constructing multi-thickness rockfill embankment with lateral confinement and layering functions

A construction method and technology of stone embankment, applied in the direction of roads, roads, buildings, etc., can solve the hidden danger of cost density, affect the whole life cycle time of the project, instability of the embankment, etc., to improve the function guarantee and quality reliability, and a good society. Economic benefits and reliable engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

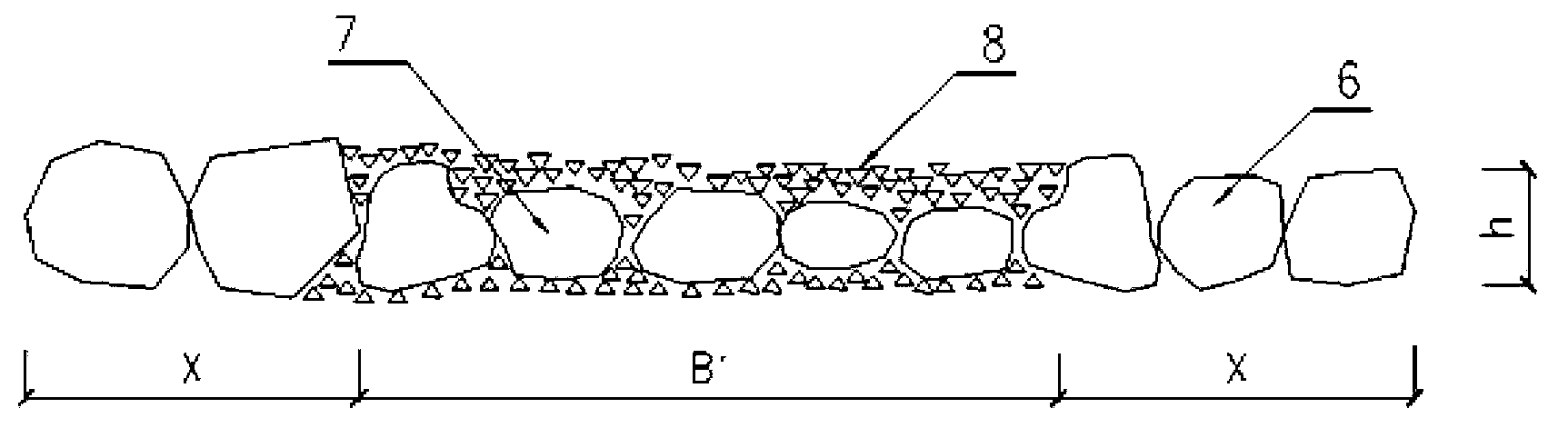

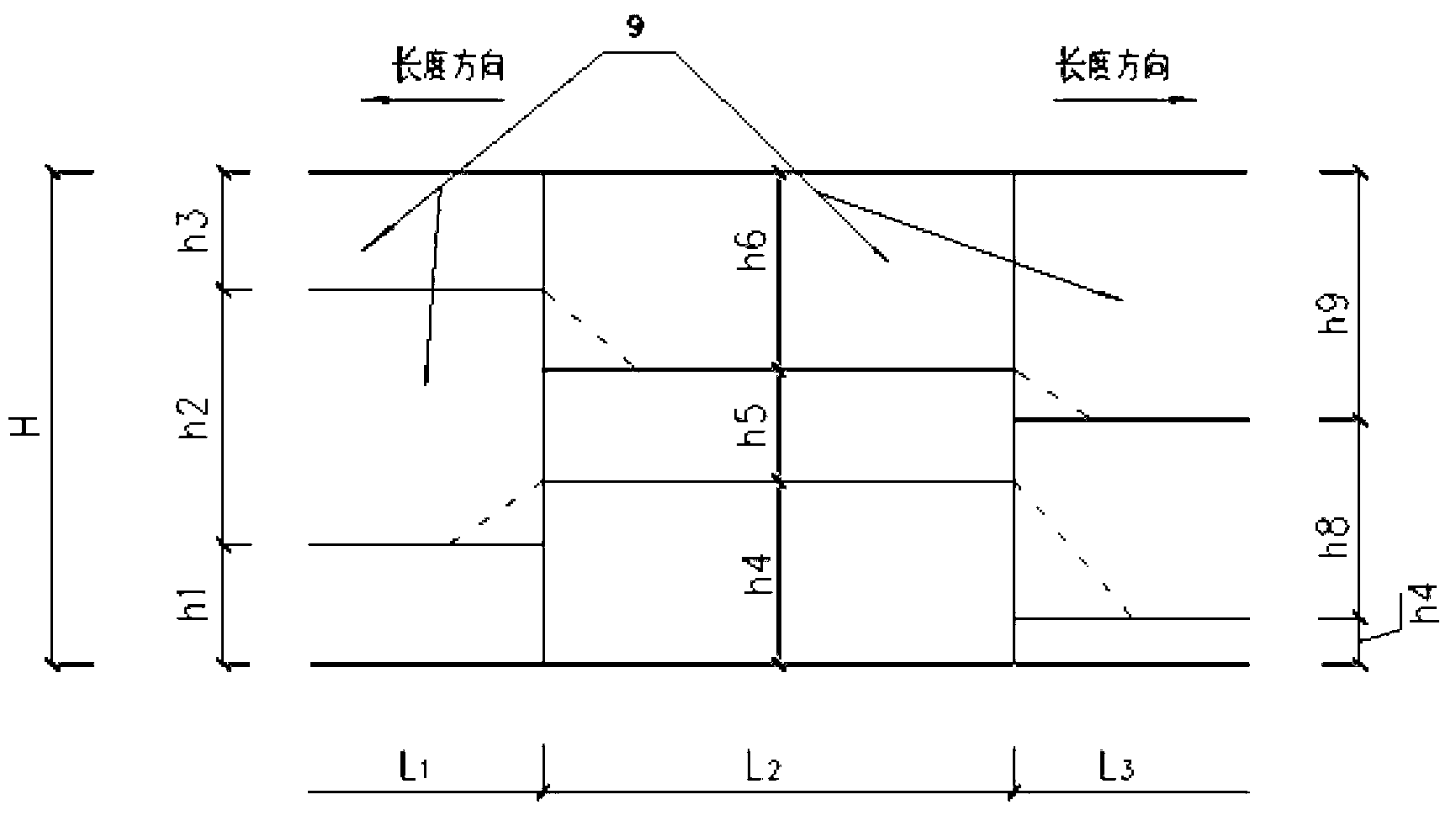

Method used

Image

Examples

Embodiment Construction

[0045] Process flow of the present invention is as follows:

[0046] Subgrade treatment→Construction lofting→Inserting rods and hanging wires→Dry laying rubble on both sides→Machinery cooperates with manual laying of rubble→Manual backfilling and paving of ballast→Road roller stabilization→Manual filling of pits→Heavy-duty roller compaction→Quality inspection→Filling Stone embankment acceptance → road bed filling.

[0047] Concrete construction process of the present invention is as follows:

[0048] (1) Construction preparation

[0049] A. Stone investigation for embankment filling

[0050] Expansive rocks, soluble rocks, strongly weathered rocks, disintegrating rocks, lithified rocks, and soft rocks with a strength lower than 15Mpa shall not be used for embankment filling.

[0051] B. Bed treatment

[0052] a bed bearing capacity

[0053] The bearing capacity of the foundation bed determines the stability of the rock-filled embankment. When the bearing capacity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com