Method for preparing thermal insulating cotton from kenaf bast

A technology of kenaf skin and thermal insulation cotton, which is applied in textiles and papermaking, papermaking, fiberboard, etc., can solve the problems of trapped people and rescue personnel casualties, toxic smoke accelerates the spread of fire, and easy breeding of bacteria, etc., and achieves good thermal insulation effect , good flame retardant performance, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

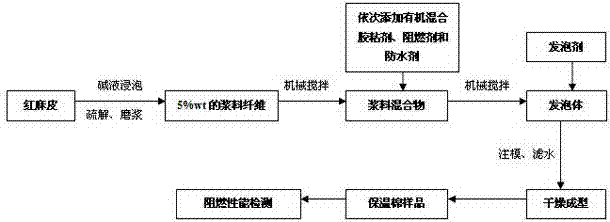

Image

Examples

Embodiment 1

[0019] (1) First peel the kenaf and wash it to get the kenaf skin.

[0020] (2) Soak the kenaf bark in 3%wt sodium hydroxide solution for 50 hours, then add water for mechanical disintegration for 12 minutes, and finally adjust the slurry concentration to 5% by refining.

[0021] (3) Add an organic mixed adhesive, a flame retardant, a waterproofing agent and a foaming agent in sequence to a 5%wt slurry aqueous solution, and foam the mixture slurry under the action of mechanical stirring to obtain a foam. Among them, the adhesive is mixed by boiling water, polyvinyl alcohol, vegetable starch, white latex and polyacrylamide (mass ratio 13:1:1:5:0.01) for a period of time, and the dosage is 60% of the dry fiber mass; The flame retardant components are chlorinated paraffin and boric acid borax (the mass ratio of boric acid and borax is 1:1), and the dosage of chlorinated paraffin and boric acid borax is 25% of the dry fiber mass; the waterproofing agent component is 15%wt of alkan...

Embodiment 2

[0025] (1) First peel the kenaf and wash it to get the kenaf skin.

[0026] (2) Soak the kenaf bark in 3%wt sodium hydroxide solution for 50 hours, then add water for mechanical disintegration for 12 minutes, and finally adjust the slurry concentration to 5% by refining.

[0027] (3) Add an organic mixed adhesive, a flame retardant, a waterproofing agent and a foaming agent in sequence to a 5%wt slurry aqueous solution, and foam the mixture slurry under the action of mechanical stirring to obtain a foam. Among them, the adhesive is mixed by boiling water, polyvinyl alcohol, vegetable starch, white latex and polyacrylamide (mass ratio 13:1:1:5:0.01) for a period of time, and the dosage is 60% of the dry fiber mass; The flame retardant components are chlorinated paraffin and boric acid borax (the mass ratio of boric acid to borax is 1:1), and the dosage of chlorinated paraffin and boric acid borax is 30% of the dry fiber mass; the waterproofing agent component is 15%wt alkane B...

Embodiment 3

[0031] (1) First peel the kenaf and wash it to get the kenaf skin.

[0032] (2) Soak the kenaf bark in 3%wt sodium hydroxide solution for 50 hours, then add water for mechanical disintegration for 12 minutes, and finally adjust the slurry concentration to 5% by refining.

[0033] (3) Add an organic mixed adhesive, a flame retardant, a waterproofing agent and a foaming agent in sequence to a 5%wt slurry aqueous solution, and foam the mixture slurry under the action of mechanical stirring to obtain a foam. Among them, the adhesive is mixed by boiling water, polyvinyl alcohol, vegetable starch, white latex and polyacrylamide (mass ratio 13:1:1:5:0.01) for a period of time, and the dosage is 60% of the dry fiber mass; The flame retardant components are chlorinated paraffin and boric acid borax (the mass ratio of boric acid to borax is 1:1), and the dosage of chlorinated paraffin and boric acid borax is 20% of the dry fiber mass; the waterproofing agent component is 15%wt of alkane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com