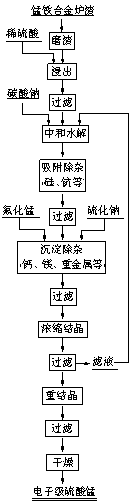

Method for preparing electronic-grade manganese sulfate by utilizing ferro-manganese alloy furnace slag

A ferromanganese alloy, electronic-grade technology, applied in the direction of manganese sulfate, etc., can solve the problems of high cost and long impurity removal process, and achieve the effects of efficient recycling, simplified impurity removal process, and abundant raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Grind ferromanganese alloy slag to a particle size of 250 Next, take 200g, put it into the leaching tank, slowly add 415g of sulfuric acid with a concentration of 50% by mass, turn on the stirrer, react and leaching at 80°C for 3 hours, and then filter. Heat the filtrate to 80°C, add sodium carbonate to adjust the pH of the solution to 6, hydrolyze the iron and aluminum ions in the solution to generate corresponding hydroxide colloids, cool the solution to 30°C, stir for 1 hour, and make the hydroxide colloids absorb the solution Impurities such as silicon and scandium in the filter are left to stand and filtered. The filtrate was heated to 95°C, the pH value was controlled to be 5, 36g of manganese fluoride was added, and the reaction was stirred for 2.5h to make the Ca in the solution 2+ , Mg 2+ Wait for the impurity ions to form insoluble fluoride precipitates, then add 15g of sodium sulfide, stir and react for 0.5h, make the heavy metal impurity ions in the solut...

Embodiment 2

[0028] Grind ferromanganese alloy slag to a particle size of 150 Next, take 200g, put it into the leaching tank, slowly add 350g of sulfuric acid with a mass percentage concentration of 60%, turn on the stirrer, react and leaching at 70°C for 2.5h, and then filter. Heat the filtrate to 90°C, add a certain amount of sodium carbonate, adjust the pH value to 6.5, and hydrolyze the iron and aluminum ions in the solution to generate corresponding hydroxide colloids, cool the solution to 40°C, stir for 2 hours, and make the hydroxide colloids Fully absorb silicon, scandium and other impurities in the solution, and then let it stand and filter. The filtrate was heated to 90°C, the pH was controlled to be 6, 33g of manganese fluoride was added, and the reaction was stirred for 2 hours to make the Ca in the solution 2+ , Mg 2+ Wait for impurity ions to form insoluble fluoride precipitates, then add 16.3g of sodium sulfide, stir and react for 1 hour, make heavy metals and other impuri...

Embodiment 3

[0031] Grind ferromanganese alloy slag to a particle size of 150 Next, take 200g, put it into the leaching tank, slowly add 430g of sulfuric acid with a mass percentage concentration of 50%, turn on the stirrer, react and leaching at 90°C for 2 hours, and then filter. Heat the filtrate to 80°C, add sodium carbonate to adjust the pH value of the solution to 6, so that the iron and aluminum ions in the solution are hydrolyzed to generate corresponding hydroxide colloids, the solution is cooled to 50°C, and stirred for 1.5h to make the hydroxide colloids fully Adsorb impurities such as silicon and scandium in the solution, and let it stand and filter. The filtrate was heated to 85°C, the pH value was controlled to 6.5, 39g of manganese fluoride was added, and the reaction was stirred for 1.5h to make the Ca in the solution 2+ , Mg 2+ Wait for impurity ions to form insoluble fluoride precipitates, then add 13.8g of sodium sulfide, stir and react for 1.5h, make heavy metals and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com