Multi-functional blowing shoe mold

A multi-functional, shoe-mold technology, used in household components, household appliances, other household appliances, etc., can solve the problems of uneven quality, uncontrollable pressure, insufficient foaming of foam materials, etc., and achieves good overall sealing performance. The effect of saving production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

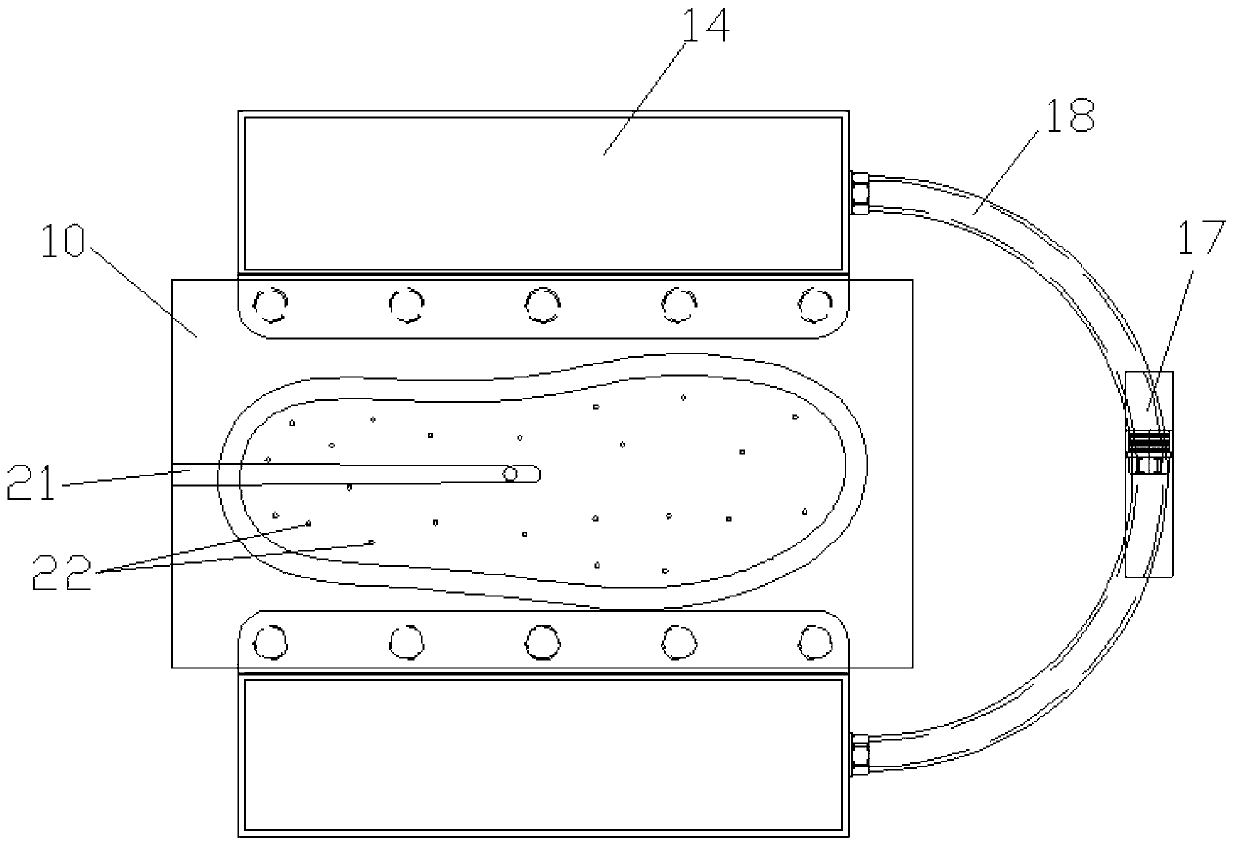

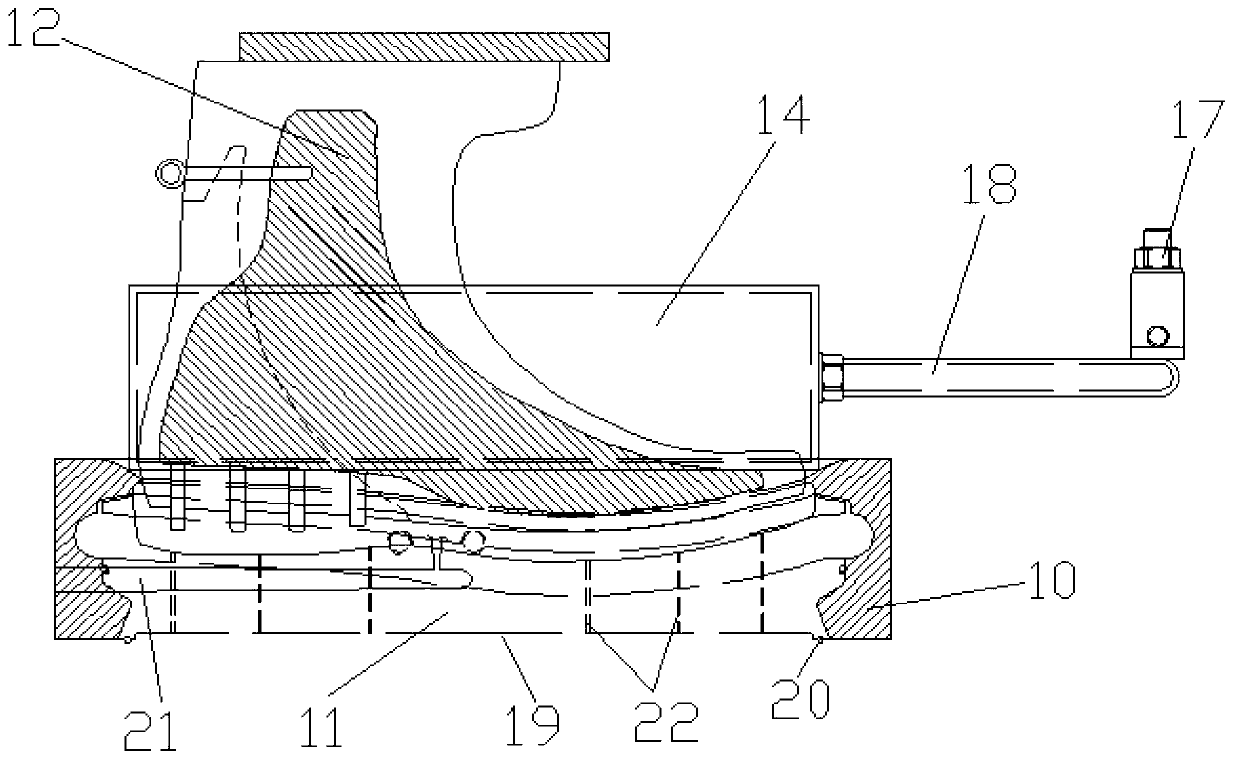

[0016] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —3: A multi-functional air-blowing shoe mold, including a mold frame 10 that can be opened and closed in the horizontal direction, an air passage 13 is arranged inside the mold frame 10, a bottom mold 11 is installed in the middle of the mold frame 10, and a shoe last 12 is located at the bottom mold 11 Directly above and corresponding to the shape and structure of the bottom mold 11, the root of the bottom mold 11 is provided with a feed port 21, wherein a constant pressure air chamber 14 is provided on one side of the mold frame 10, and the bottom of the shoe last 12 and the bottom mold 11 The formed sole molding cavity 15 communicates with the constant pressure air chamber 14 through the air channel 13 .

[0017] According to the above-mentioned multifunctional air-blowing shoe mold, wherein, the bottom of the bottom mold 11 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com