Novel protective shoe upper production technique

A production process and technology for protective shoes, which are applied to shoe uppers, footwear, boot legs, etc., can solve problems such as inability to effectively protect the instep, lack of rebound external force impact protection, etc., to save tedious process steps, beautiful appearance, The effect of improving the protection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

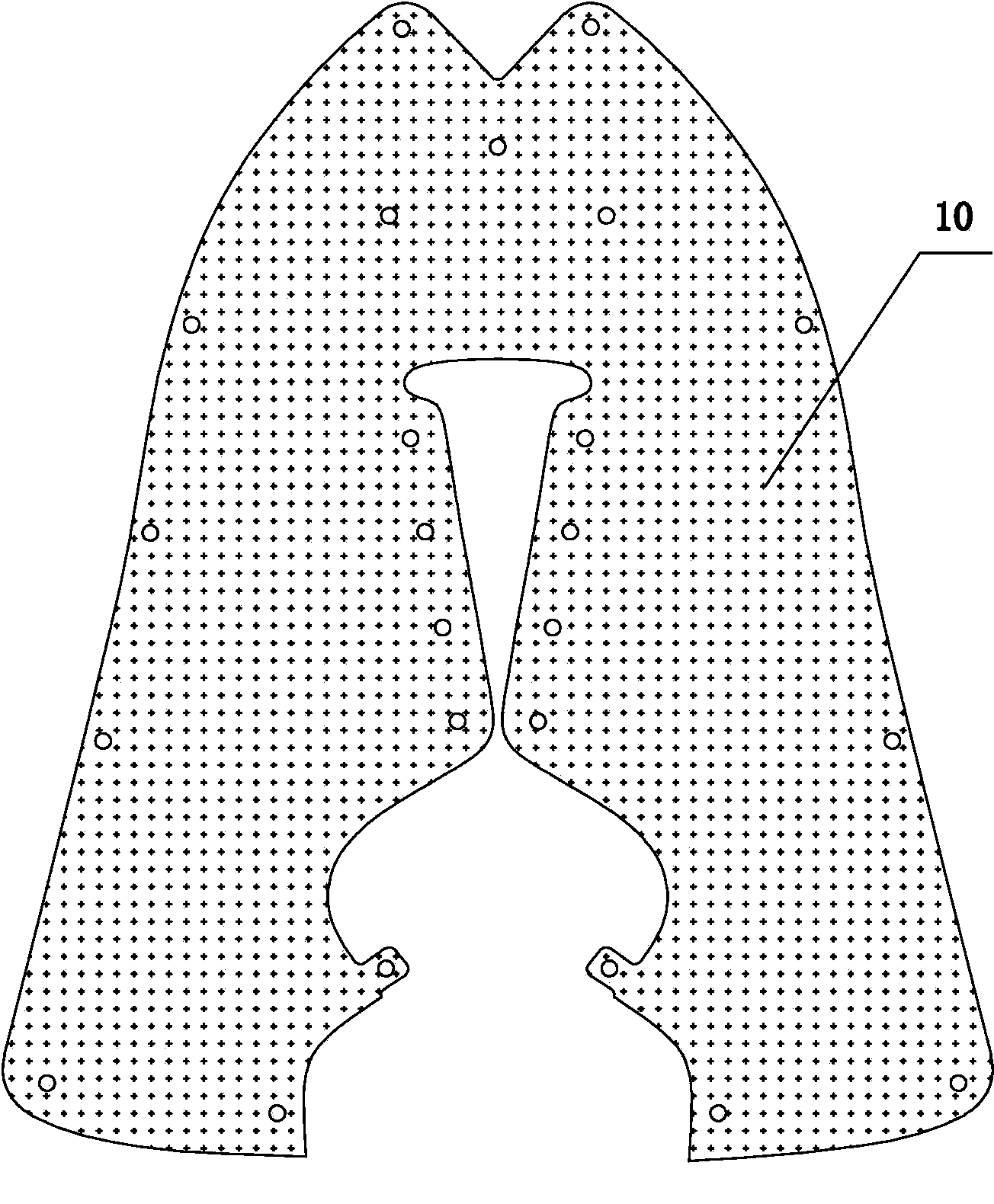

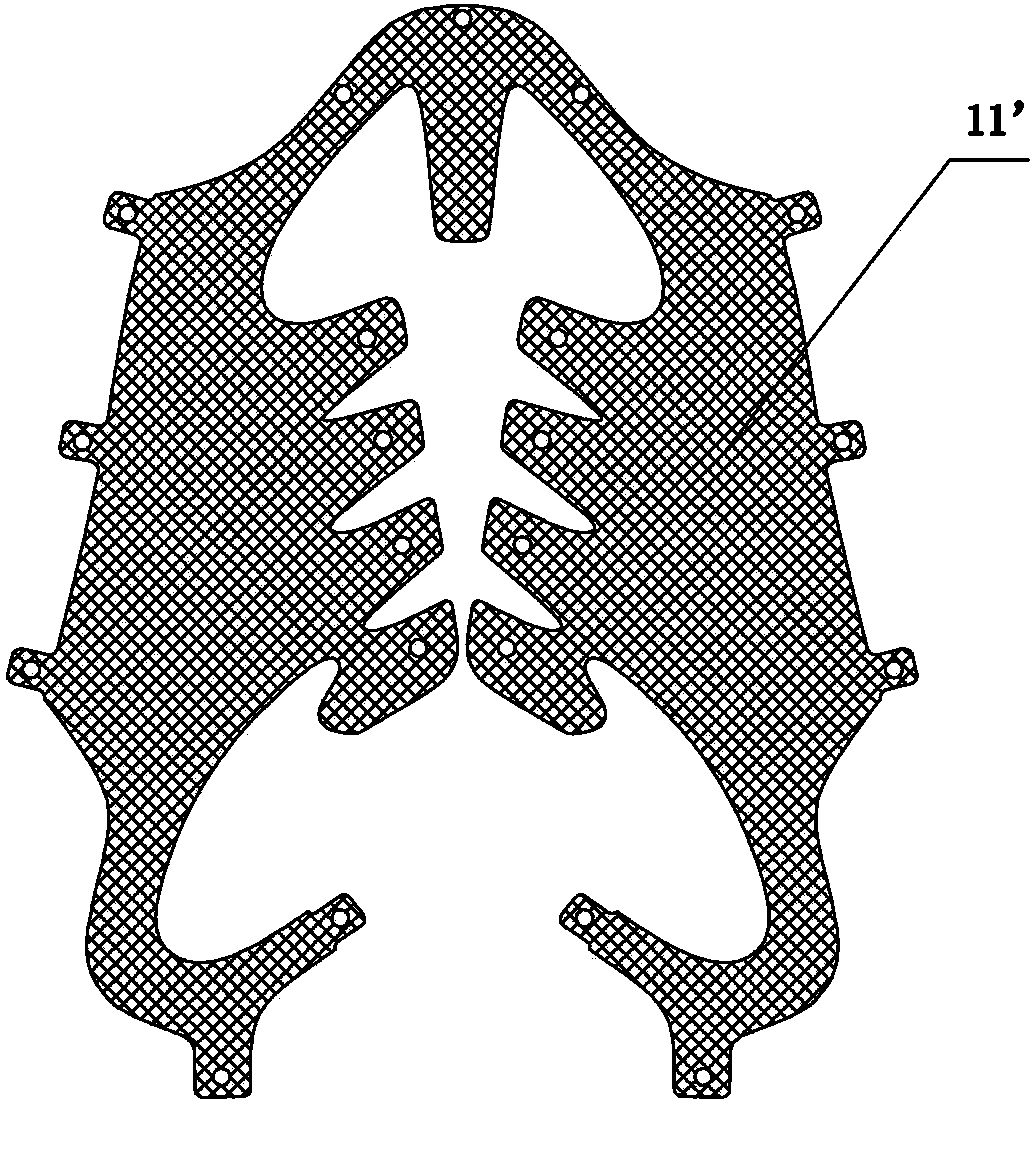

[0034] refer to figure 1 , image 3 and Figure 6 . A novel protective vamp 1, comprising a vamp bottom layer 10 and a protective layer located on the upper surface of the vamp bottom layer 10, the protective layer is an EVA foam layer 11, and the EVA foam layer 11 is bonded by a Layer and the upper bottom layer 10 are integrally formed by mold pressing, the upper bottom layer 10 is the bottom layer of nylon mesh fabric, the adhesive layer is the adhesive glue coated on the surface of the EVA foam layer 11, In this embodiment, the adhesive glue adopts activated glue.

[0035] The manufacture method of above-mentioned a kind of novel protective shoe upper is as follows steps:

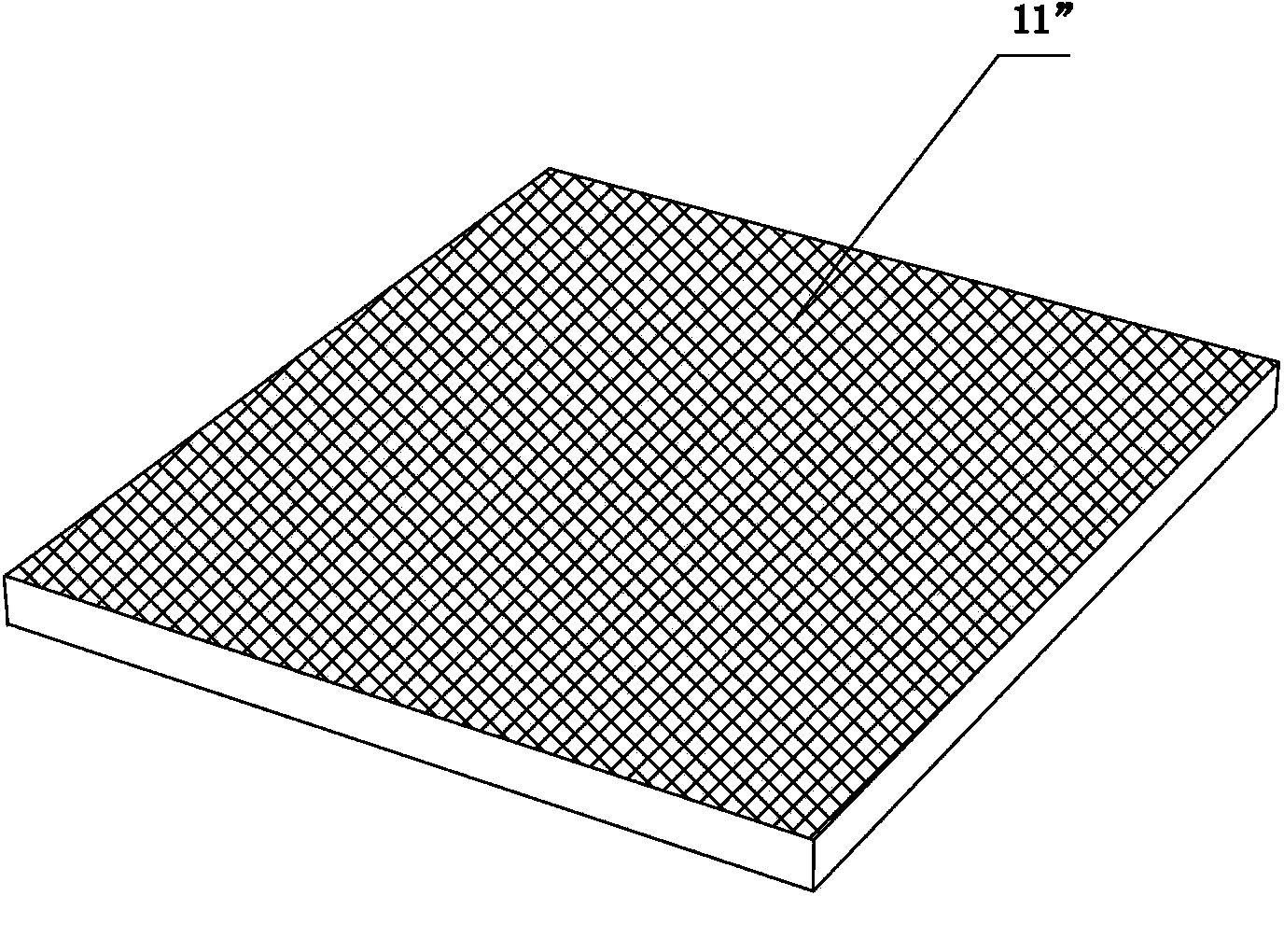

[0036] The first step, refer to figure 2 , adding processing aids, bridging agents, foaming agents, active agents and colorants to the EVA raw materials, after full mixing, the rollers are rolled out into sheets, and then the EVA foam is formed by heating and pressurizing chemical reactions , and ...

Embodiment 2

[0042] refer to figure 1 , image 3 and Figure 6 . A novel protective vamp 1, comprising a vamp bottom layer 10 and a protective layer located on the upper surface of the vamp bottom layer 10, the protective layer is an EVA foam layer 11, and the EVA foam layer 11 is bonded by a Layer and the upper bottom layer 10 are integrally formed by mold pressing, the upper bottom layer 10 is a bottom layer of polyester fabric, and the adhesive layer is an environmentally friendly film. In this embodiment, an environmentally friendly film made of EVA material is preferred.

[0043]The manufacture method of above-mentioned a kind of novel protective shoe upper is as follows steps:

[0044] The first step, refer to figure 2 , adding rubber raw materials, processing aids, bridging agents, foaming agents, active agents and colorants to the EVA raw materials, after full mixing, they are rolled out into sheets, and then formed by heating and pressurizing chemical reactions EVA foam, the...

Embodiment 3

[0050] The embodiment of this embodiment is substantially the same as that of Example 2, except that the hardness of the EVA foam layer 11" in the steps of the manufacturing method is 55C, and the finished EVA foam layer after mold pressing Layer 11 has a hardness of 70C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com