Insert, holder and post-treatment unit for exhaust gases

An insert and containment technology, which is applied in the field of inserts of containment parts, can solve the problems that the post-processing unit cannot meet the conventional requirements of exhaust gas, the seal is not airtight enough, and leaks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

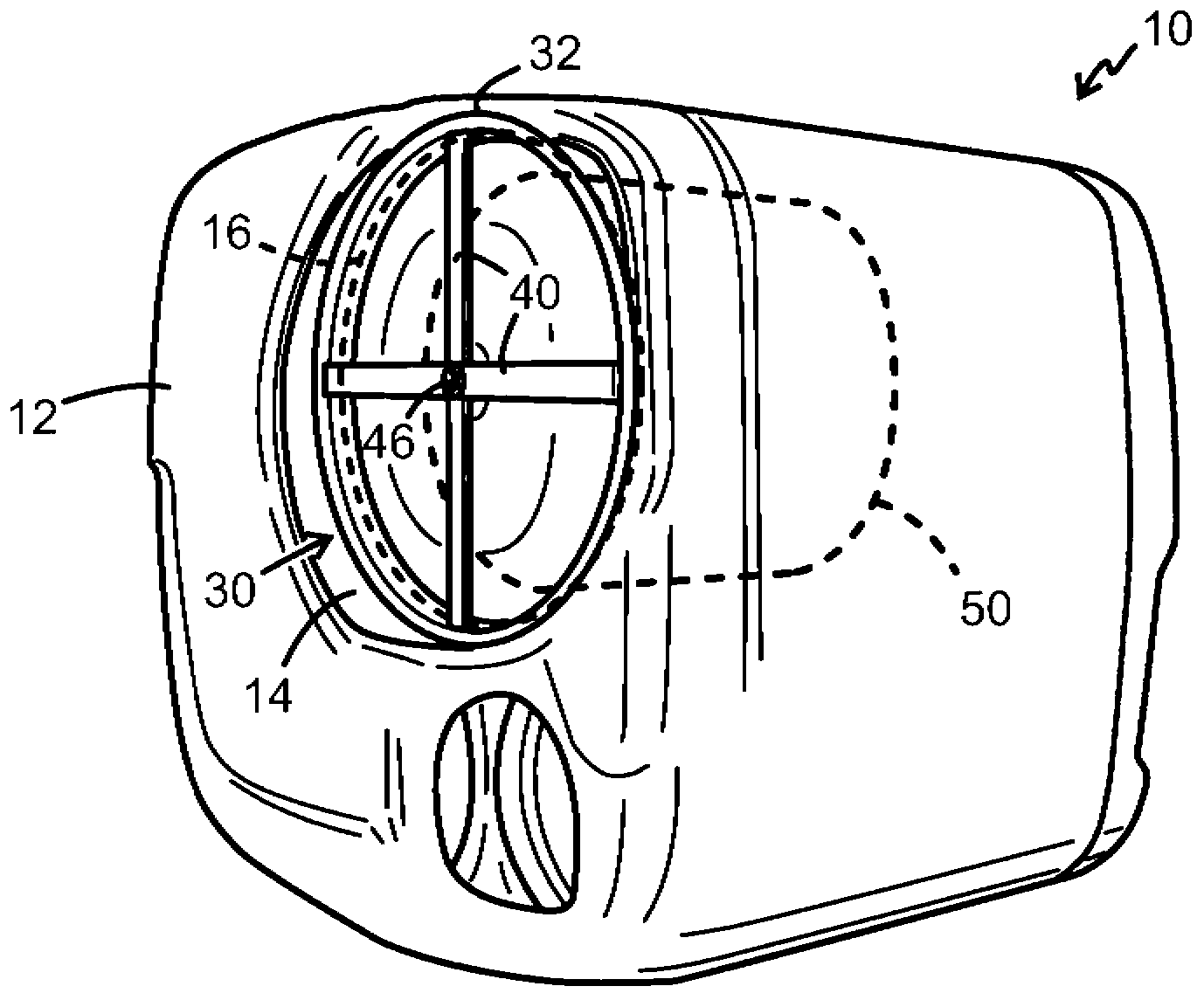

[0021] figure 1 An exhaust aftertreatment unit 10 is shown for a not shown internal combustion engine such as, for example, a diesel engine of a truck. The aftertreatment unit 10 comprises, in a known manner, a housing 12 with inlet and outlet openings, not shown in detail, for engine exhaust gas. Device 10 may have one or more interchangeable inserts, for example by figure 1 The inserts 50, represented in dashed lines, each include a treatment component including a substrate (such as an oxidation catalyst, SCR catalyst, or wall flow filter) configured to flow exhaust gas therethrough.

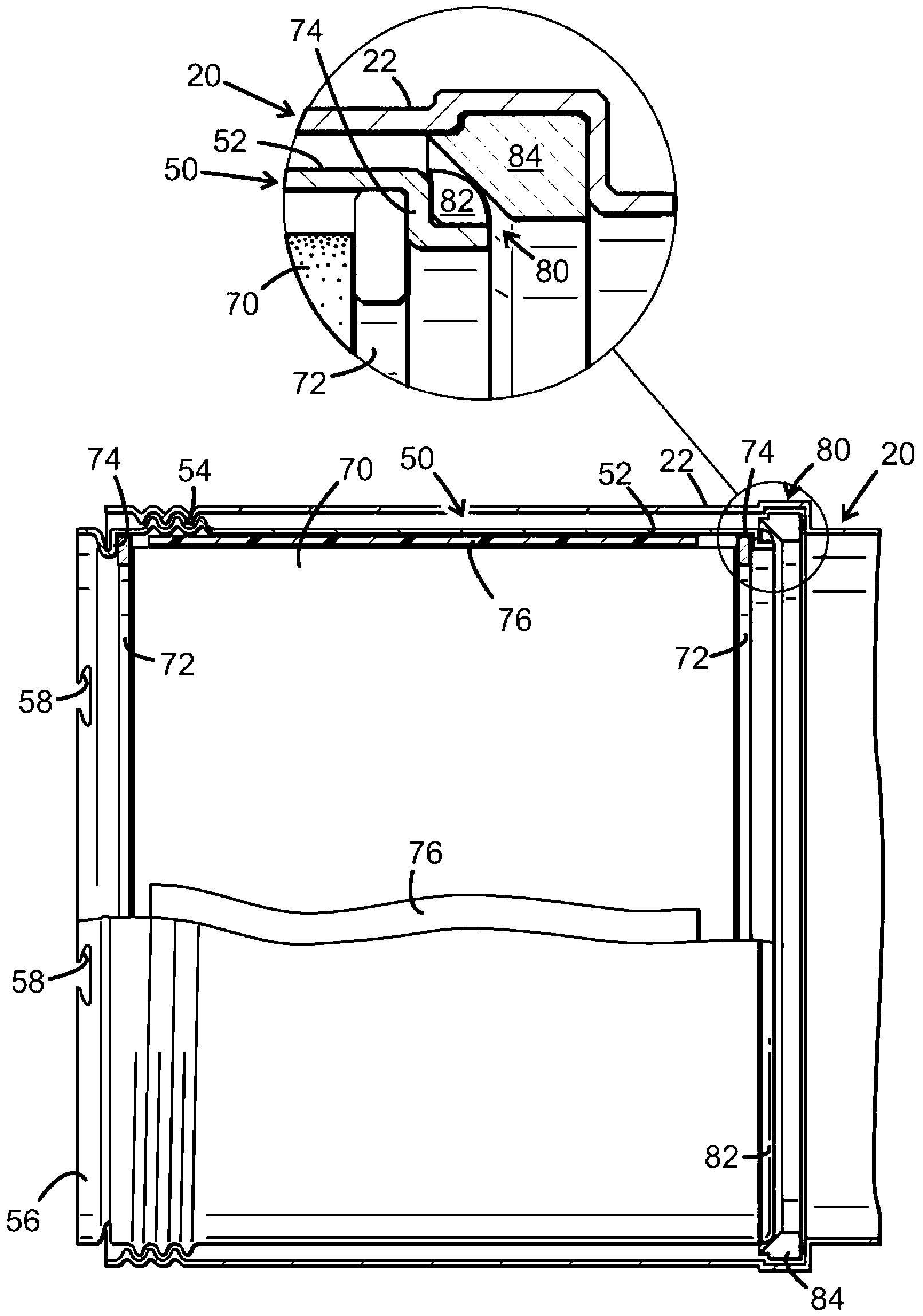

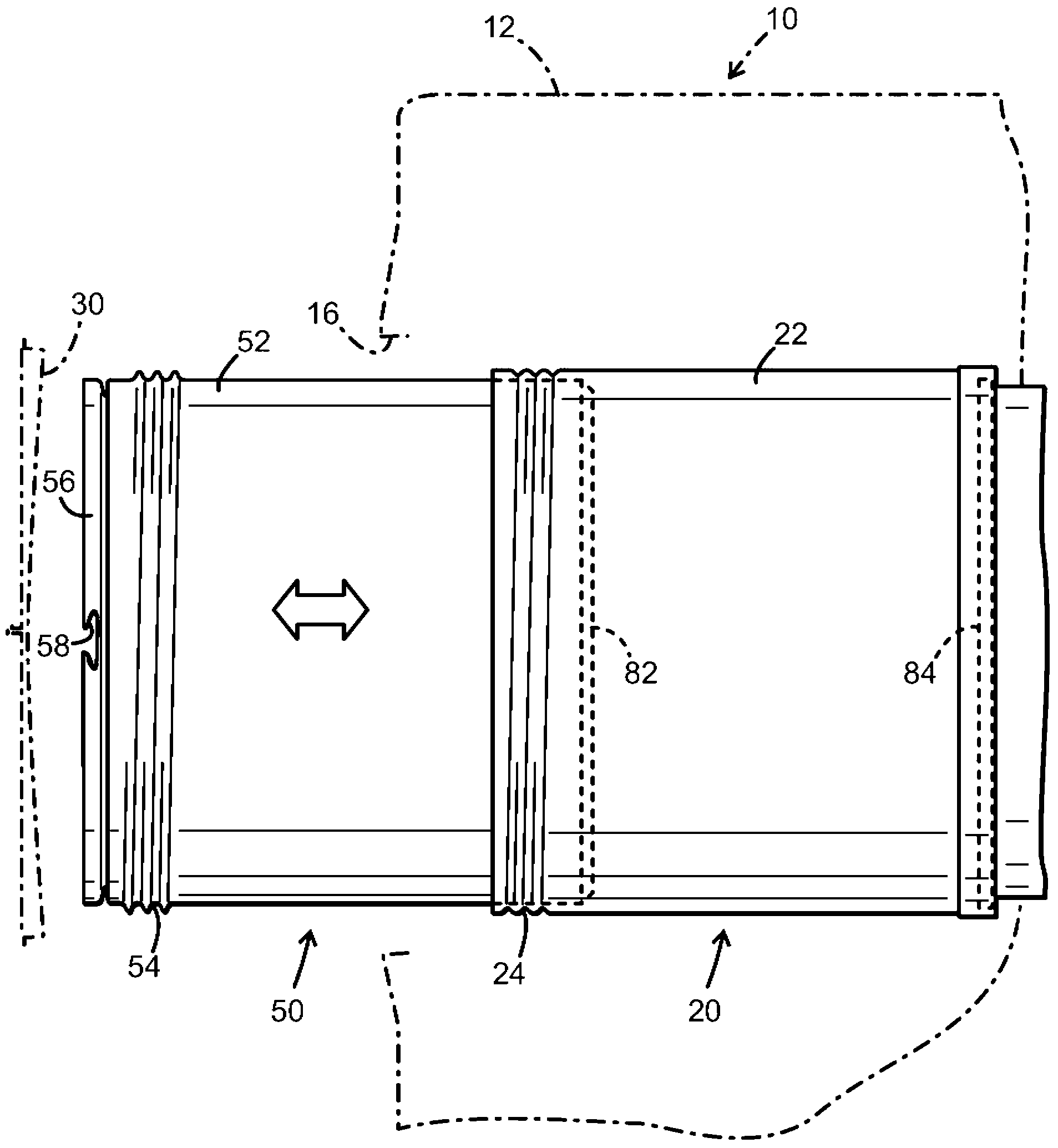

[0022] Such as figure 2 As shown, the insert 50 has a thin-walled bushing 52 or "sleeve" that is open at both ends and into which a base 70 is pushed and then passed through a pair of opposing locks. A ring 72 is axially secured, the locking ring itself being secured by annular shoulders 74 formed at opposite ends of the bushing 52 . The base 70 also has a radial support in the form of an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com