Distributed circular machine control system based on STM 32 and FPGA

A technology of control system and circular knitting machine, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of control system not working normally, poor system scalability, insufficient stability, etc., to improve reliability and Scalability, versatility, and the effect of improving development efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

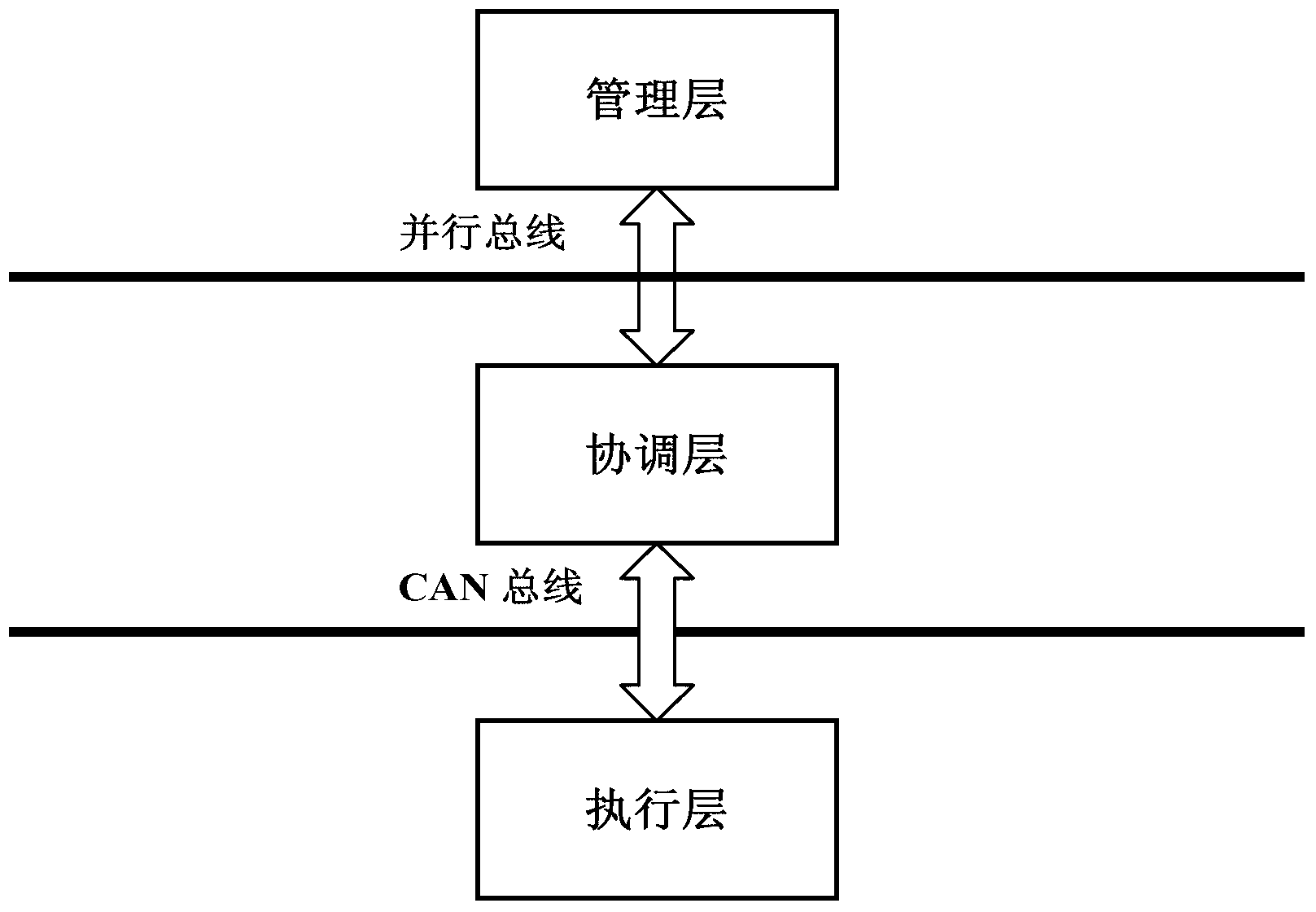

[0031] A distributed circular machine control system based on STM32 and FPGA, such as figure 1 As shown, the hierarchical structure framework is adopted, and the distributed control method is used. From top to bottom, it is divided into management layer, coordination layer, and execution layer in turn. The management layer and the coordination layer are connected through a parallel bus, and the coordination layer and the execution layer are connected through the CAN bus. connect.

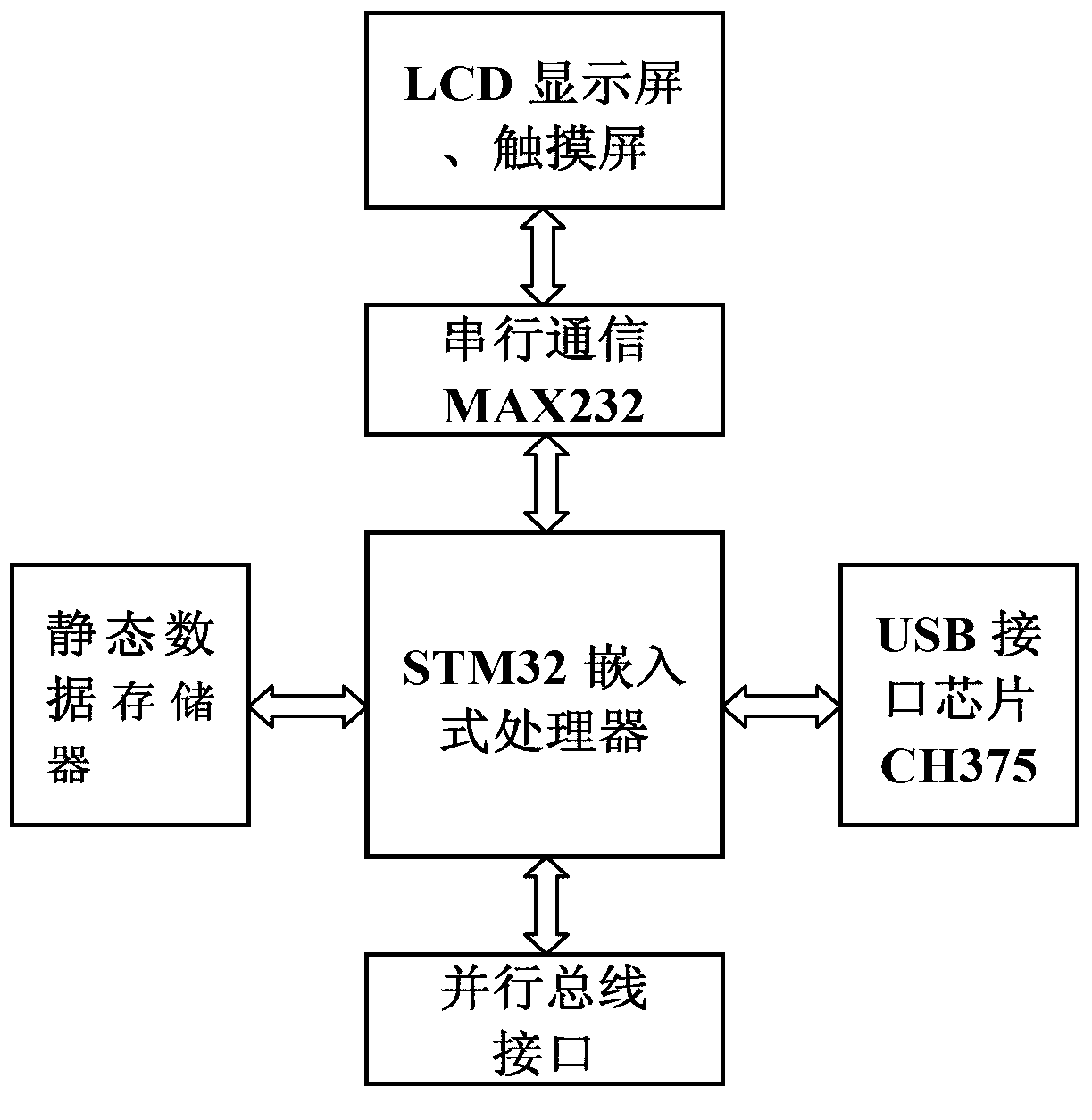

[0032] Such as figure 2 As shown, the management team includes STM32 embedded processor STM32F103ZG, static data memory (SRAM) IS62WV51216, USB device interface driver chip CH375, serial communication chip MAX232, LCD display, touch screen. The LCD display and touch screen are connected to the serial port of the STM32 embedded processor through the serial communication chip MAX232; the static ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com