Pipe thermal conductivity tester and test method

A technology of thermal conductivity and testing method, which is applied in the field of pipe thermal conductivity tester and testing, can solve the problems of no national standard for thermal conductivity testing, lack of thermal conductivity, no testing equipment, etc., and achieve friendly man-machine interface, low production cost, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

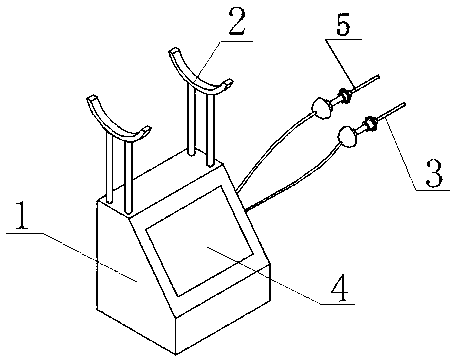

[0022] like figure 1 As shown, a pipe thermal conductivity tester includes a test host 1, a touch screen 4 is arranged on the test host 1, and the touch screen 4 is used for operation and control during the thermal conductivity test. The touch screen 4 is provided with a test start button, Test end button, setting button, refresh button, historical curve button, data export button, real-time status button, system description button and other buttons are convenient for operation; a pair of sample pipe brackets 2 are arranged on the top of the test host 1, and In order to place the sample pipe, the test host 1 is also equipped with a temperature sensor I3 and a temperature sensor II5. The test host 1 is equipped with a power module and a control module for providing power. The temperature sensor I3 and temperature sensor II5 are connected to the control module. It is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com