Supporting method capable of preventing roof and wall falling accidents

A technology of roofing and roofing, which is applied in earth-moving drilling, temporary shielding, mining equipment, etc., can solve problems such as roofing accidents, uncertainty of roofing, roofing of roofs, etc., so as to prevent roofing and reduce the amount of roofing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below is a further description of an embodiment of the present invention:

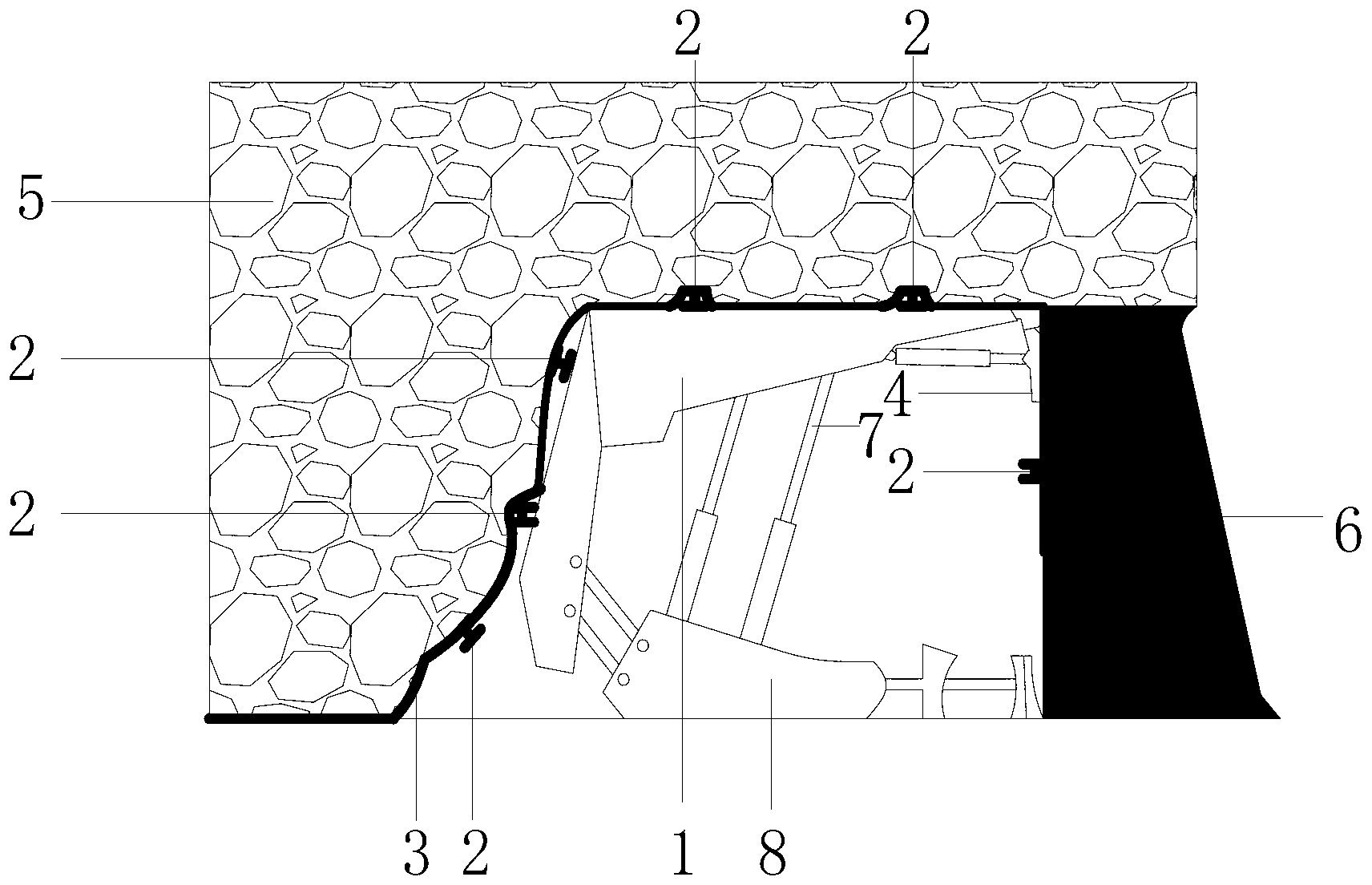

[0013] The present invention is a support method for the roof side of the anti-cavitation. Firstly, when the cutout is made on the working face, the roof of the cutout section of the whole working face is pre-laid and connected with a fixed metal mesh with a specification of 5.0m×1.0m. The mesh material is 10# iron wire, the mesh is a diamond-shaped weaving hole, the mesh is 0.04m×0.04m, and then the hydraulic support is installed in the cutout. And use the hydraulic support to support the side plate against the coal wall; when laying the net, first spread the net along the working surface, and then connect with the front net of the hydraulic support in turn. , the distance between the mesh buckles shall not be greater than 200mm, and the metal mesh in front of the hydraulic support is bound horizontally with iron wire to a length of 5m, 9# I-beam; when mining coal, the side guard is retracted, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com