Construction method and elastic binders for bonding lightweight concrete board wall, and wallboards

An elastic adhesive and lightweight concrete technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as difficulty in guaranteeing bonding quality, inconvenient construction, and affecting the appearance of walls , to achieve the effect of improving sound insulation, crack resistance, impermeability and waterproof performance, which is conducive to production and optimized structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

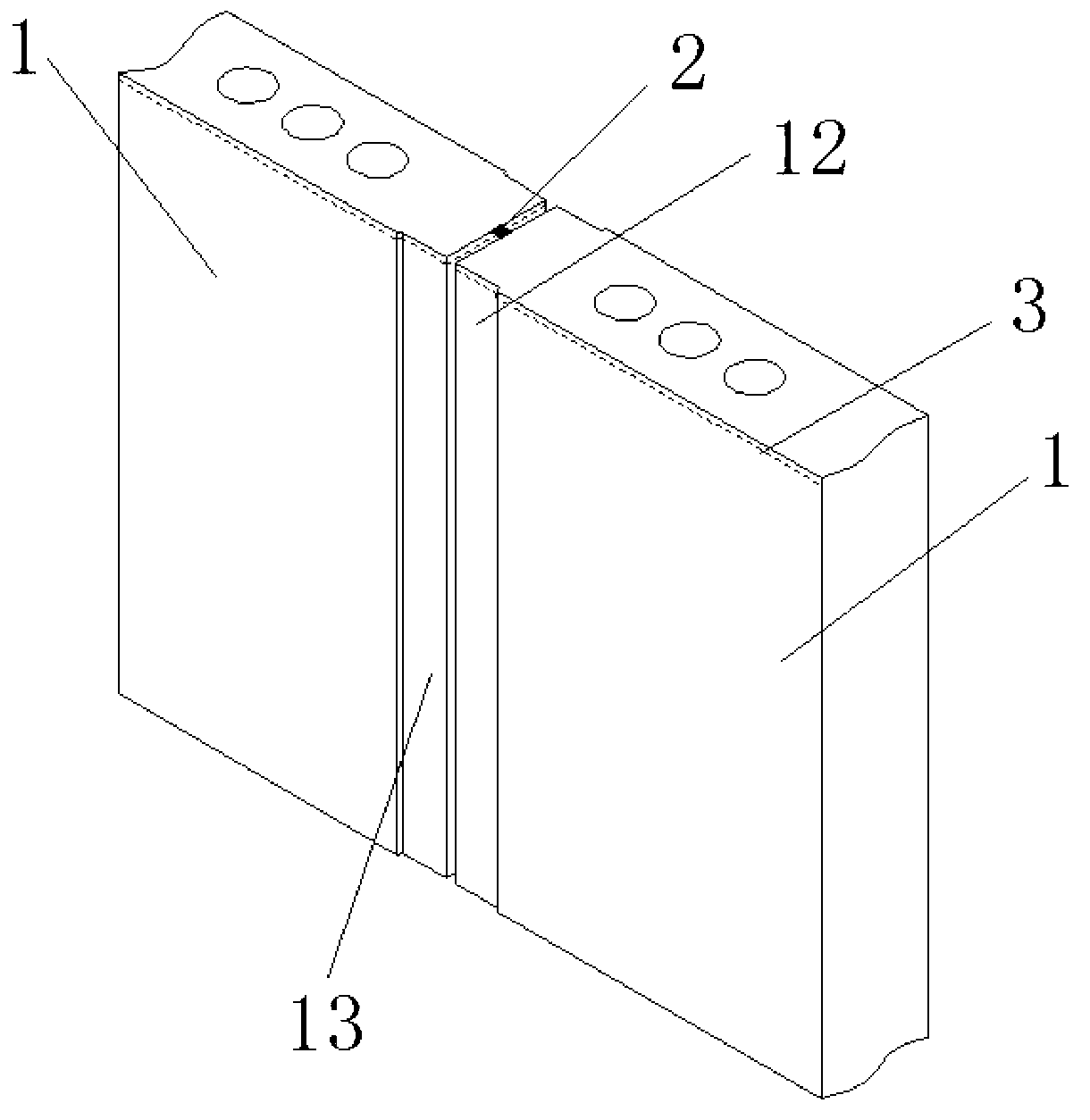

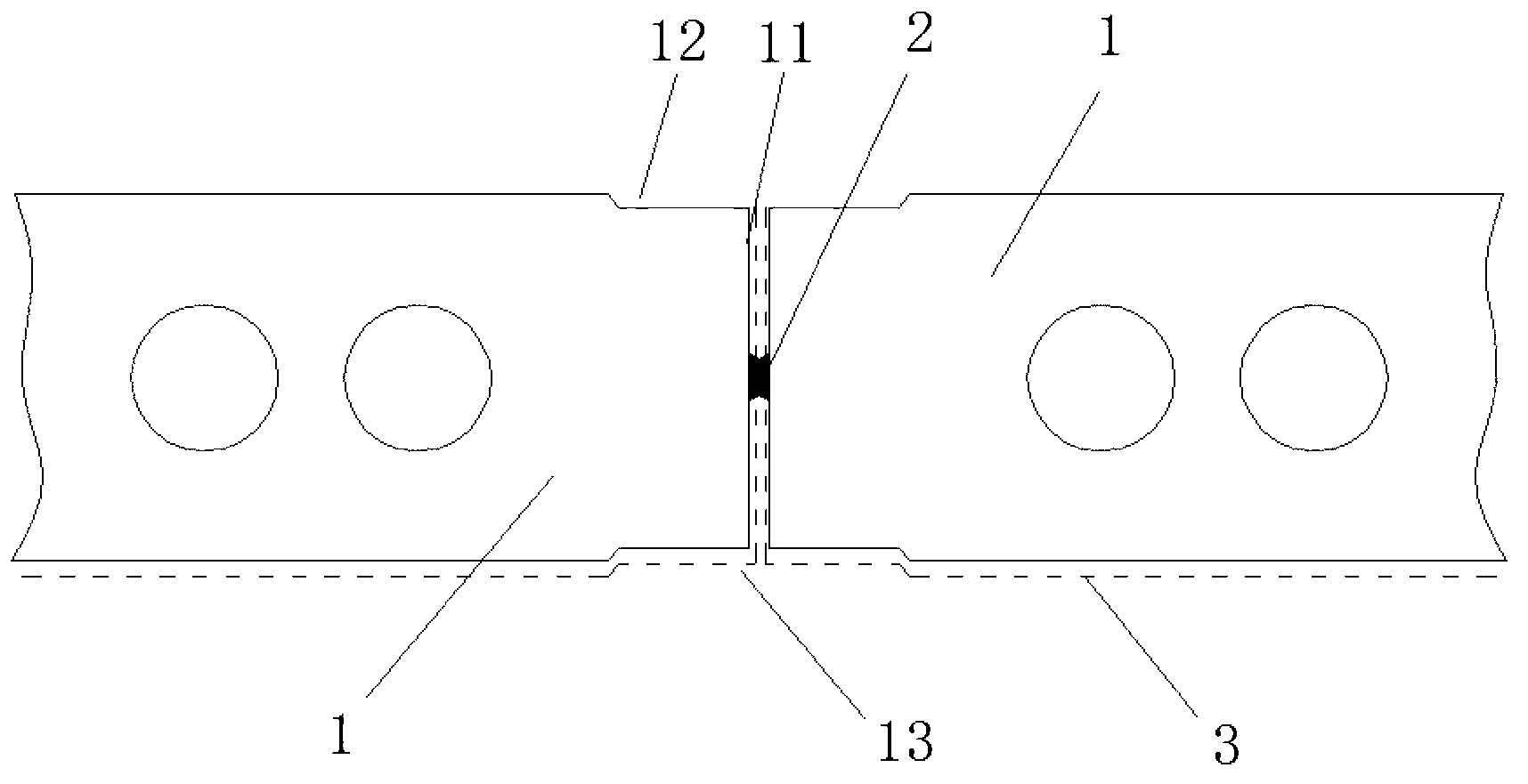

[0031] Examples, see Figure 1 to Figure 5 According to the construction method for bonding lightweight concrete slab walls provided by the present invention, the bonding base surface 11 of the wall panel 1 is a plane shape, and an elastic adhesive is arranged between the wall panel 1 and the bonding base surface 11 of the wall panel 1 2. Bonding and splicing the wallboards 1 into a board wall, realizing the construction method with simple construction operation and good bonding quality between the wall boards and the wall boards. The board wall completed by splicing has good sound insulation, earthquake resistance, crack resistance, seepage resistance and waterproof performance .

[0032] The wallboard 1 and the wallboard 1 are spliced and bonded by the elastic adhesive 2 to form a flat panel wall, or spliced and bonded to form the external corner of the panel wall, or spliced and bonded to form a T-shaped structure of the panel wall, or spliced and bonded A board wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com