Construction method of occlusion pile of full reinforcement pile

A construction method and occlusal pile technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of high rigidity requirement of enclosure body, great influence of foundation pit deformation, excessive cutting of plain piles, etc. Small water seepage probability, large envelope stiffness, and the effect of increasing steel content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is further described below, but protection scope of the present invention is not limited thereto:

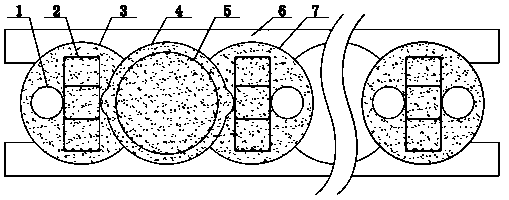

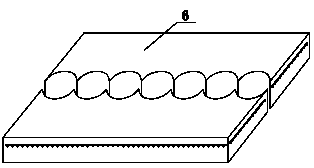

[0041] Such as Figure 1-2 As shown, the occlusal pile of a kind of fully reinforced pile of the present invention comprises a group of square reinforced concrete piles and circular reinforced concrete piles which are successively occluded and connected at intervals. The square reinforced concrete pile is composed of square reinforced cage 2 and conventional Concrete pouring forms, and described circular reinforced concrete pile is formed by circular reinforcement cage 5 and conventional concrete pouring, in order to improve the firmness of square reinforcement cage, the present invention is respectively fixedly arranged in the long side both sides of square reinforcement cage with a diameter of 250mm PVC pipe, the construction method of the occlusal pile is as follows:

[0042] 1) Construction preparation and pile position measurement and setting o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com