A Concrete Structure Applied to Sectional Casting Method

A technology of concrete structure and segmental pouring, which is applied in the direction of building components, building structure, construction, etc., and can solve the problems of affecting the bearing capacity of concrete, weakening of concrete bonding force, and easy cracking of construction joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, so that those skilled in the art can implement it with reference to the description.

[0031] It should be understood that terms such as "having", "comprising" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

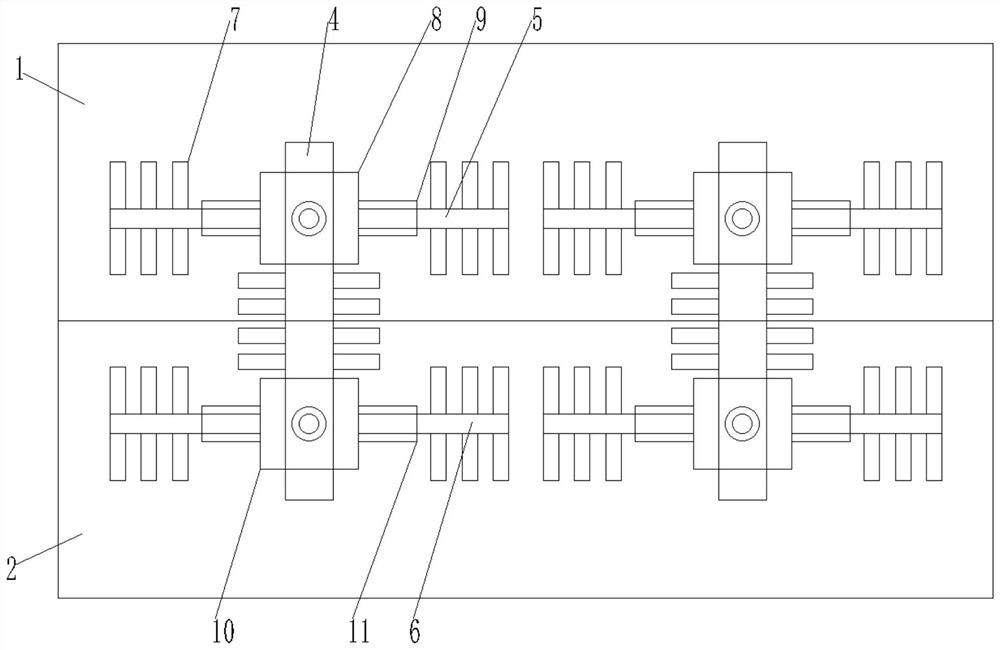

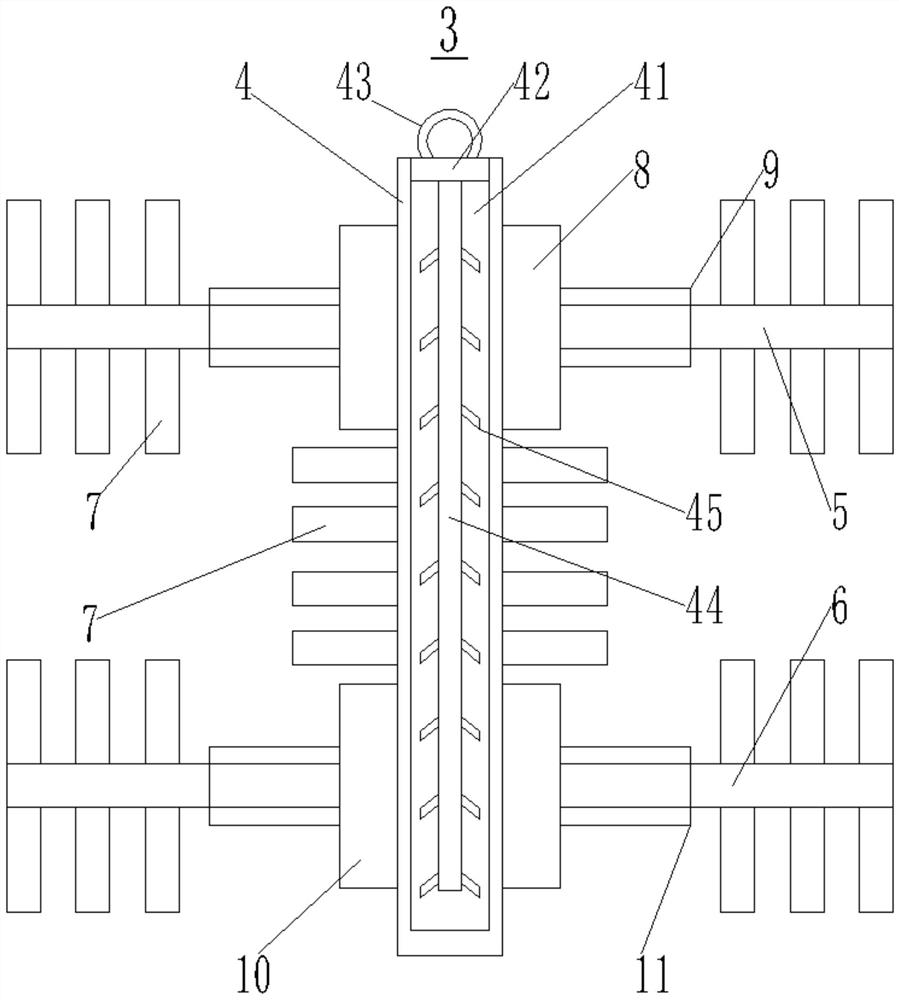

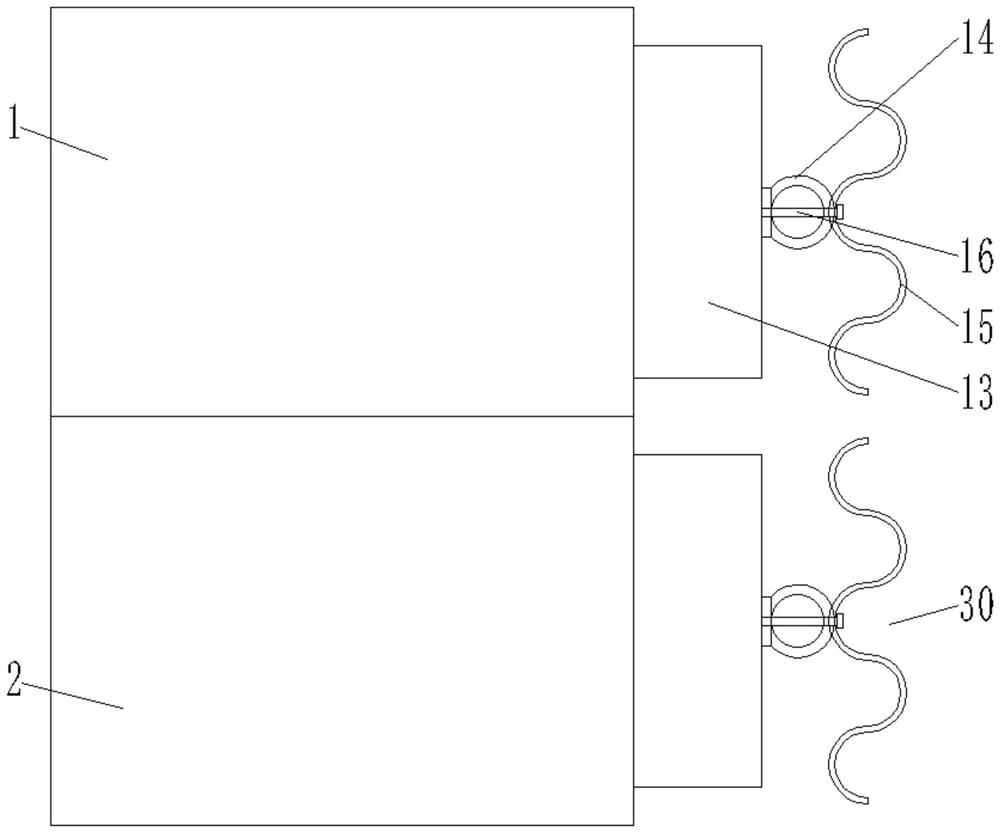

[0032] Such as Figure 1-Figure 4 Shown, the present invention provides a kind of concrete structure that is applied to segmental pouring method, comprises:

[0033] The first concrete layer 1, the second concrete layer 2 and the connecting piece 3, the connecting piece 3 includes a vertical connecting section 4, a plurality of first horizontal connecting sections 5, a plurality of second horizontal connecting sections 6, a plurality of The first horizontal connecting section 5 is completely placed in the first concrete layer 1, and the plurality of second horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com