steel reinforced concrete well wall

A steel reinforced concrete and steel plate technology, which is applied to shaft equipment, earthmoving, wellbore lining, etc., can solve the problems of limited increase in steel content inside the shaft wall and insignificant contribution to the horizontal bearing capacity of the shaft wall, etc., so as to reduce engineering costs. , Wide applicability, high steel content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Drilling method shaft wall (prefabricated in sections, with annular flange plates at both ends of the shaft wall)

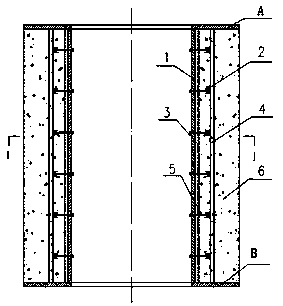

[0043] The steel plate steel-reinforced concrete shaft wall created by the present invention is mainly composed of steel plate cylinder 1, circumferential steel frame 2 (H-shaped steel), inner vertical steel frame 3 (H-shaped steel), outer vertical steel frame 4 (H-shaped steel), diameter Composed of connecting piece 5 and concrete 6 (see Picture 1-1 with Figure 1-2 ).

Embodiment approach

[0045] (1) On the flange plate at the lower end of the shaft wall, arrange the outer vertical steel frame 4 and the inner vertical steel frame 3 along different ring diameters (the ring spacing and circumferential spacing can be adjusted as required) and welded to the flange plate;

[0046] (2) Install and fix the section steel arc section to the outer vertical steel frame 4, and form a closed circumferential steel frame 2 by welding or bolt connection; then install and fix the pre-bent formed curved steel plate to the inner vertical steel frame 3. , The closed steel plate cylinder 1 is formed by welding;

[0047] (3) Utilize the radial coupling 5 to connect the steel plate cylinder 1 and the circumferential steel frame 2 to form a space structure;

[0048] (4) Install the upper flange plate and weld it firmly to the inner vertical steel frame, the outer vertical steel frame, and the steel plate cylinder;

[0049] (5) Install the external formwork and supporting structure required for...

Embodiment 2

[0051] Example 2: Drilling method shaft wall (prefabricated in sections, with annular flange plates at both ends of the shaft wall)

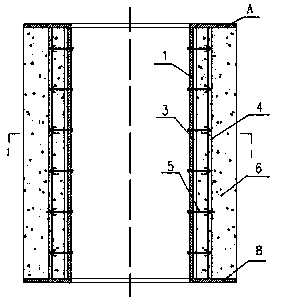

[0052] The steel plate steel-reinforced concrete shaft wall created by the present invention is mainly composed of steel plate cylinder 1, circumferential steel frame 2 (channel steel), inner vertical steel frame 3 (channel steel), outer vertical steel frame 4 (channel steel), diameter Composed of connecting piece 5 and concrete 6 (see diagram 2-1 with Figure 2-2 ).

[0053] Implementation method: same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com