Steel pipe hollow concrete building floor and construction method thereof

A technology of hollow concrete and construction method, which is applied in the direction of floors, building components, buildings, etc., can solve problems such as easy cracks or cracks, cumbersome construction process, poor anti-crowding ability, etc., to overcome cracks or cracks, save manpower and The effect of time and bearing capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

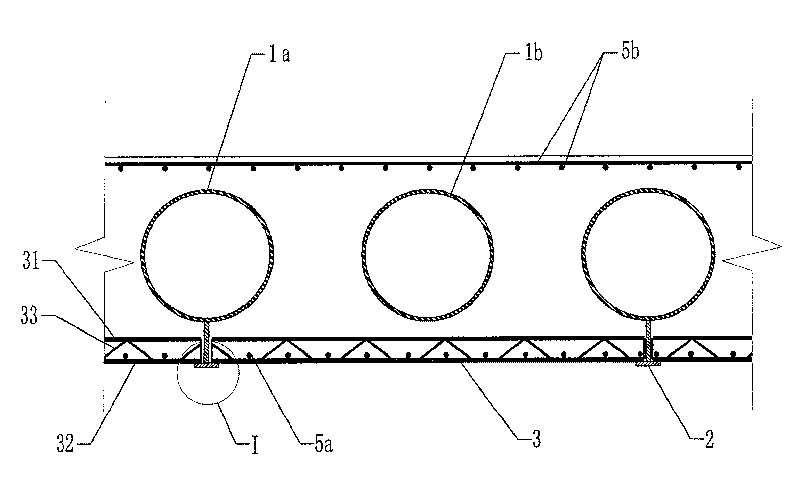

[0133] Embodiment 1 of the present invention is as Figure 1~4 and Figures 8 to 13 Shown, a kind of construction method of steel pipe hollow concrete slab, it specifically comprises the following steps:

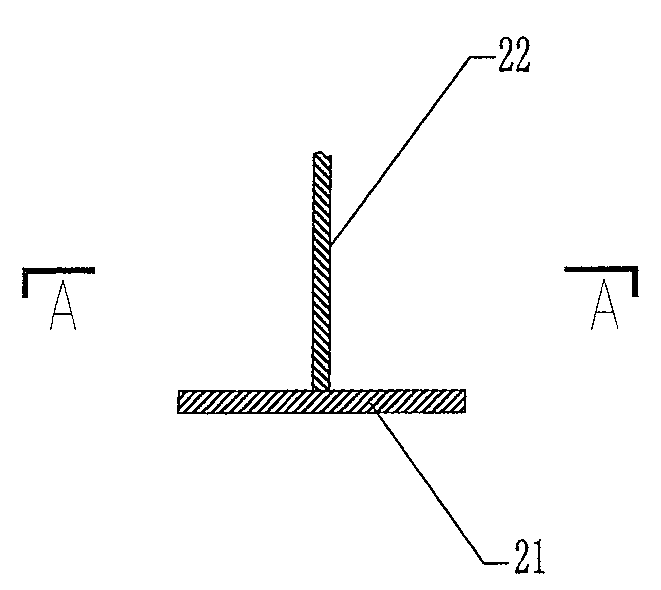

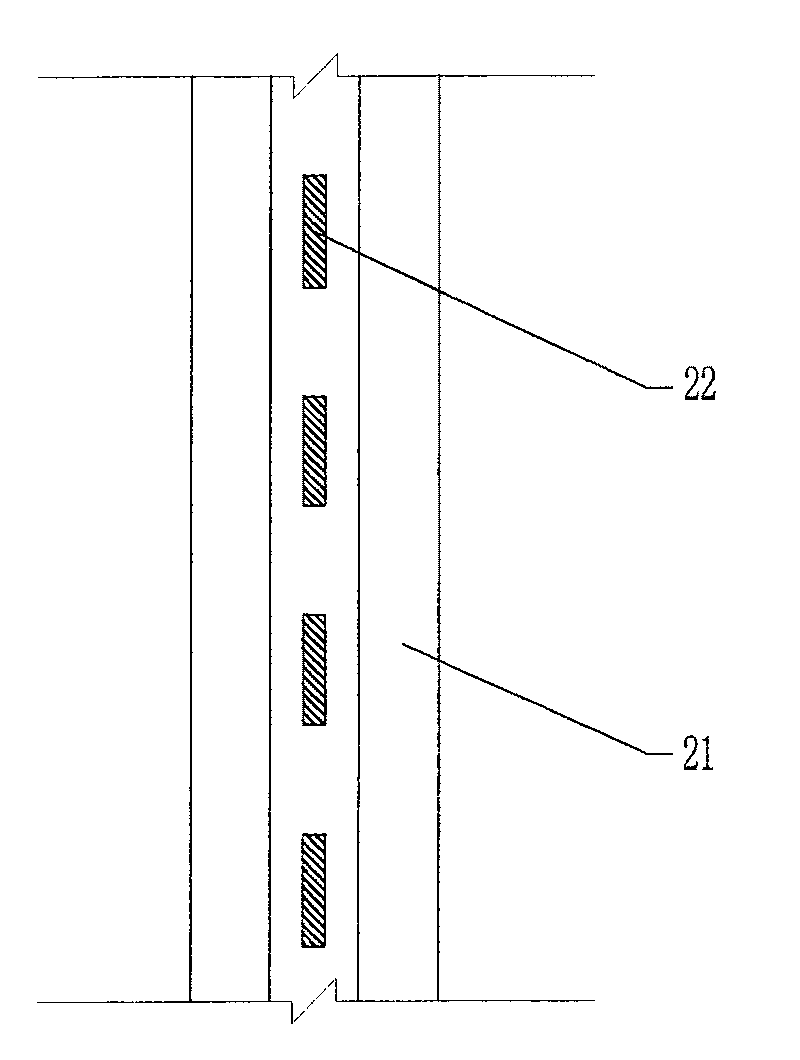

[0134] (1). If Figure 8As shown, two sets of steel pipes 1a and 1b are made, and the first set of steel pipes 1a is fixedly installed on the bracket 2. The bracket 2 is composed of a horizontally arranged supporting plate 21 and a vertically arranged hanging plate 22. The supporting plate 21 and the first group The length of the steel pipe 1a is adapted; the hanging plate 22 is located under the first group of steel pipes 1a, and includes a plurality of vertical plates vertically fixed on the supporting plate 21 and arranged at intervals along the length direction of the supporting plate 21, and the upper end of the vertical plate It is welded and fixed with the first group of steel pipes 1a; the first group of steel pipes 1a is first arranged in parallel, and its two end...

Embodiment 2

[0142] Implementation of the present invention 2 as Figure 5 As shown, the difference from the previous embodiment is that in the concrete between the adjacent two steel pipes 1a and 1b, there is also a prestressed steel hinge line 8, and the prestressed steel hinge line 8 is a parabolic shape with a concave middle. The two ends of the prestressed steel hinge line 8 pass through the square beam 4, and are fixed on the side wall on the outside of the square beam 4 with bolts 9. In the construction process, in step 4, when installing another group of steel pipes 1b, the prestressed steel strand 8 is pre-embedded and fixed at the same time. Other construction process is identical with embodiment 1.

Embodiment 3

[0144] Embodiment 3 of the present invention is as Figure 6 As shown, the difference from Embodiment 1 is that there is also a frame beam 10 in the middle of the floor, and the frame beam 10 is perpendicular to the arrangement direction of the steel pipes 1a, 1b, so that each steel pipe does not span the width of the entire floor, but Divided into two zones by frame beams 10 located in the middle of the floor. In steps 1 and 4 of the construction method, one end of the steel pipe 1a or 1b is respectively fixed on both sides of the frame beam 10 located in the middle, and the other end of the steel pipe 1a or 1b is fixed to the square beams 4 on both sides. Other construction process is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com