A method for preparing graphene or ultra-thin carbon film with PVD technology

A graphene, ultra-thin technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve problems such as unfavorable energy saving and environmental protection, small output size, difficult thickness control, etc., to reduce energy and resources. The effect of small consumption, small shape and size requirements, and precise and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

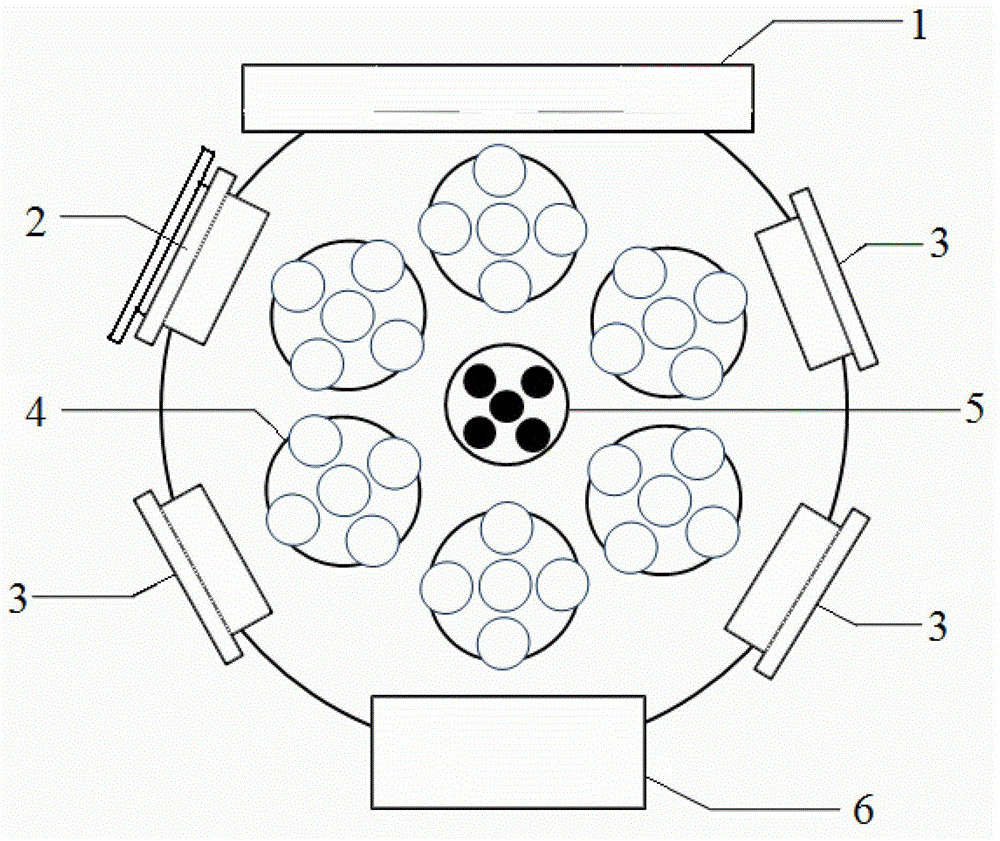

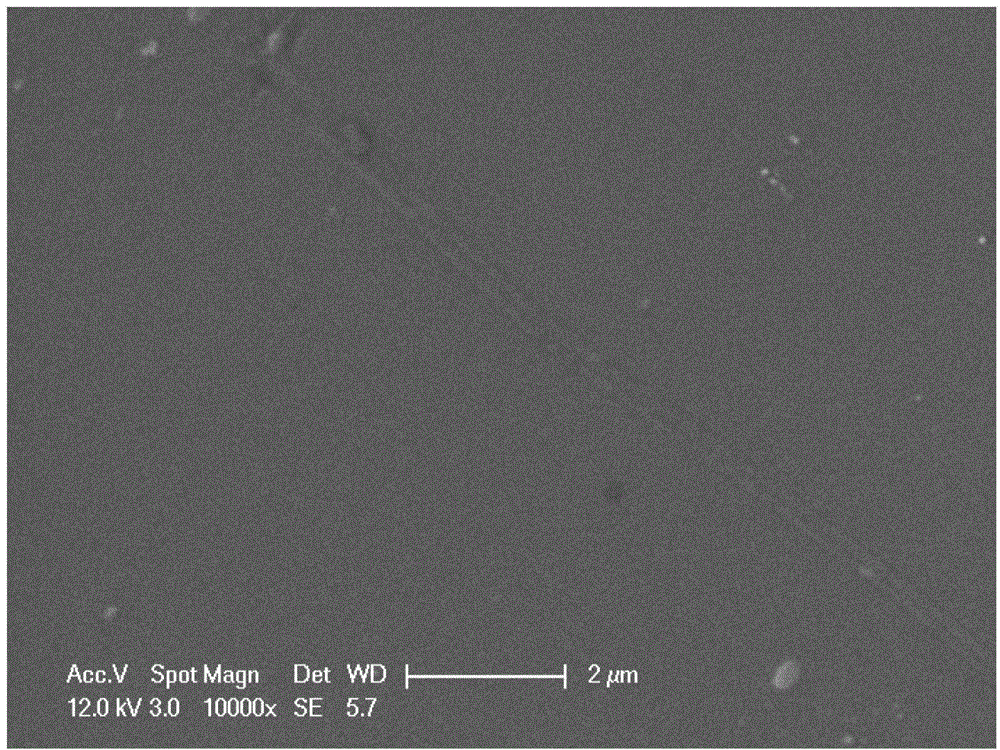

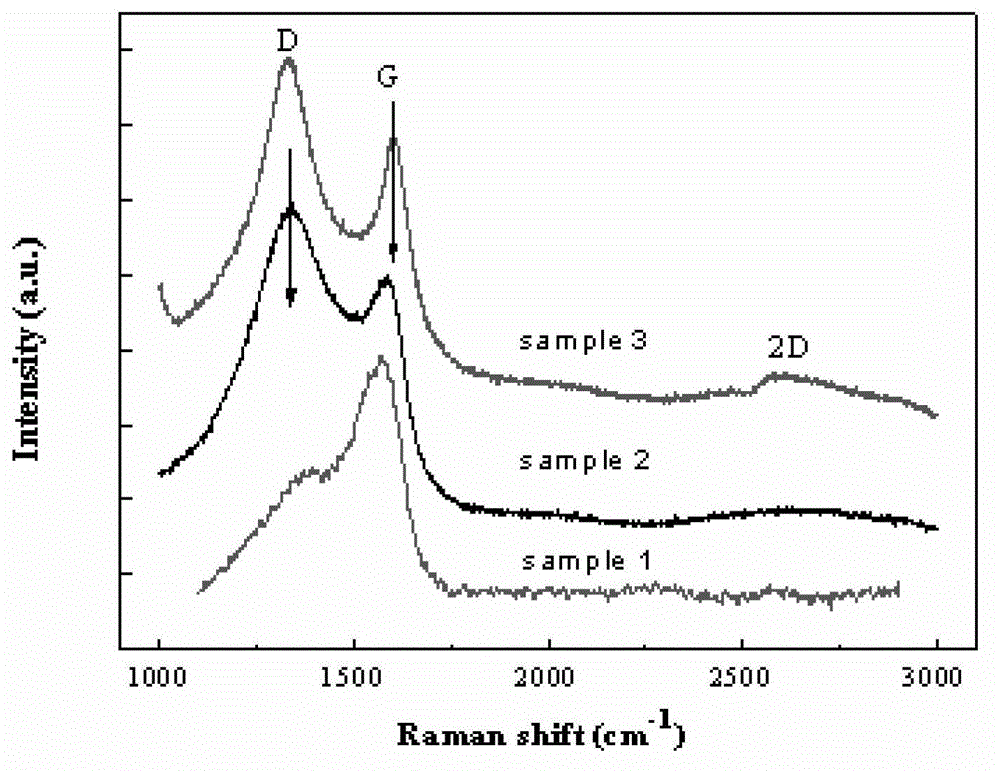

[0027] The preparation process in this example is as follows: first, the substrate is placed on the substrate holder in the deposition chamber, and the substrate surface Perform glow cleaning for 20 minutes; then, under the conditions of argon environment and substrate bias -200V, a mixed gas of acetylene and argon is introduced into the deposition chamber, the pressure is 0.55 Pa, the flow rate of acetylene in the mixed gas is 10 sccm, and the argon The flow rate of the gas is 70sccm; the ion source of the anode layer is turned on to ionize the mixed gas, the voltage is 450V during the ionization, the ion source of the anode layer generates a stable ionization current of 1.4A, and the acetylene is ionized to produce carbon-containing cations, and the cations are in the Under the action of an electric field, the substrate is bombarded and deposited on the substrate. The deposition time is 10 minutes. During the deposition process, the substrate rotates with the substrate holder...

Embodiment 2

[0030]The preparation process in this example is as follows: first, the substrate is placed on the substrate holder in the deposition chamber, under the conditions of 90°C, argon atmosphere, vacuum degree of 2.5Pa, and substrate bias of -800V, the surface of the substrate is Perform glow cleaning for 20 minutes; after the glow cleaning of the substrate surface is completed, under the conditions of argon environment, substrate bias voltage -100V, and vacuum degree of 0.7Pa, open the multi-arc target, and the target material is high-purity metal copper. The voltage on the metal target is 20V, the current is 40A, the metal is deposited on the surface of the substrate to form a metal catalyst layer, the deposition time is 10min, and the copper metal target is turned off. Then, under the conditions of argon environment and substrate bias-200V, a mixed gas of acetylene and argon is introduced into the deposition chamber, the air pressure is 0.8 Pa, the flow rate of acetylene in the m...

Embodiment 3

[0032] The preparation process in this example is as follows: firstly, the substrate is placed on the substrate holder in the deposition chamber, and the substrate surface Perform glow cleaning for 20 minutes; after the glow cleaning of the substrate surface is completed, open the multi-arc target under the conditions of argon atmosphere, substrate bias voltage -200V, and vacuum degree of 0.5Pa. The target material is high-purity nickel metal. The voltage on the metal target is 20V, the current is 100A, the metal is deposited on the surface of the substrate to form a metal catalyst layer, the deposition time is 10min, and the copper metal target is turned off. Then, under the condition of argon environment and substrate bias voltage -200V, a mixed gas of acetylene and argon is introduced into the deposition chamber, the pressure is 0.6Pa, the flow rate of acetylene in the mixed gas is 20 sccm, and the flow rate of argon gas is 60 sccm; Turn on the ion source of the anode layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com