Polyurethane foaming agent

A polyurethane foam and foaming agent technology, applied in the field of polyurethane foam, can solve the problems of unfavorable product energy-saving applications, poor thermal insulation performance, and easy premature gasification, etc., to reduce the saturated gas phase density, improve thermal insulation performance, and improve The effect of solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

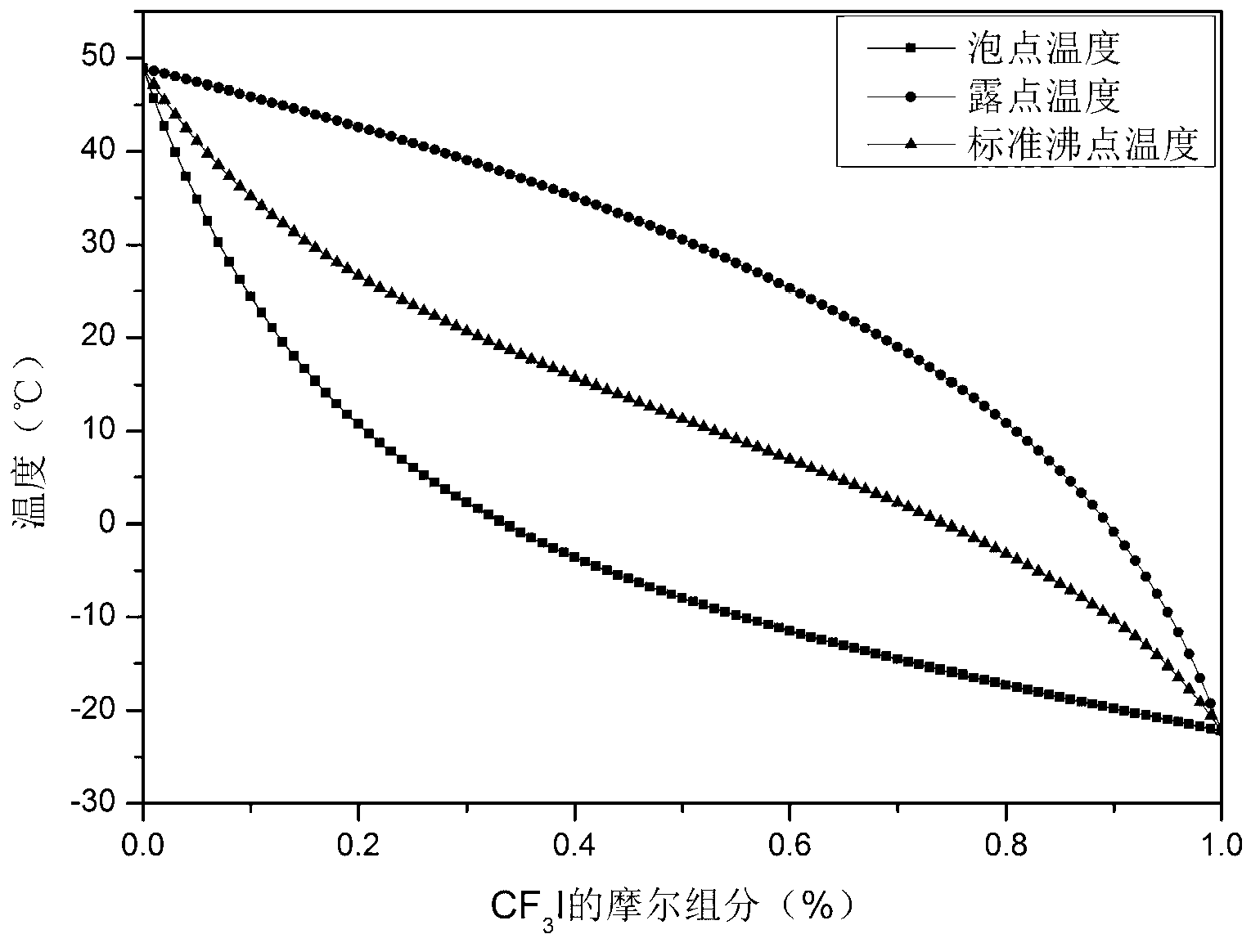

[0015] A kind of polyurethane foam blowing agent of the present embodiment comprises iodotrifluoromethane CF 3 The cyclopentane c-C5 of I, wherein: the molar percentage of trifluoroiodomethane is 10%, and the molar percentage of cyclopentane is 90%, and both are mixed homogeneously, promptly make mixed blowing agent. Calculate the thermal conductivity of the gas-phase foaming agent at room temperature 24°C and 0°C according to ASTM requirements, and the results of the thermal conductivity of the mixture are listed in Table I and Table II.

Embodiment 2

[0017] A kind of polyurethane foam blowing agent of the present embodiment comprises iodotrifluoromethane CF 3 The cyclopentane c-C5 of I, wherein: the molar percentage of trifluoroiodomethane is 20%, and the molar percentage of cyclopentane is 80%, and both are mixed homogeneously, promptly make mixed blowing agent. Calculate the thermal conductivity of the gas-phase foaming agent at room temperature 24°C and 0°C according to ASTM requirements, and the results of the thermal conductivity of the mixture are listed in Table I and Table II.

Embodiment 3

[0019] A kind of polyurethane foam blowing agent of the present embodiment comprises iodotrifluoromethane CF 3 The cyclopentane c-C5 of I, wherein: the molar percentage of trifluoroiodomethane is 30%, and the molar percentage of cyclopentane is 70%, and both are mixed homogeneously, promptly make mixed blowing agent. Calculate the thermal conductivity of the gas-phase foaming agent at room temperature 24°C and 0°C according to ASTM requirements, and the results of the thermal conductivity of the mixture are listed in Table I and Table II.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com