Oil-resistant silicon rubber and preparation method thereof by in-situ reaction

A silicone rubber and oil-resistant technology, applied in the field of oil-resistant silicone rubber and its in-situ reaction preparation, can solve the problems of affecting the performance of silicone rubber materials, high production cost, poor compatibility, etc., and achieve high-efficiency rubber processing technology and improve oil resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

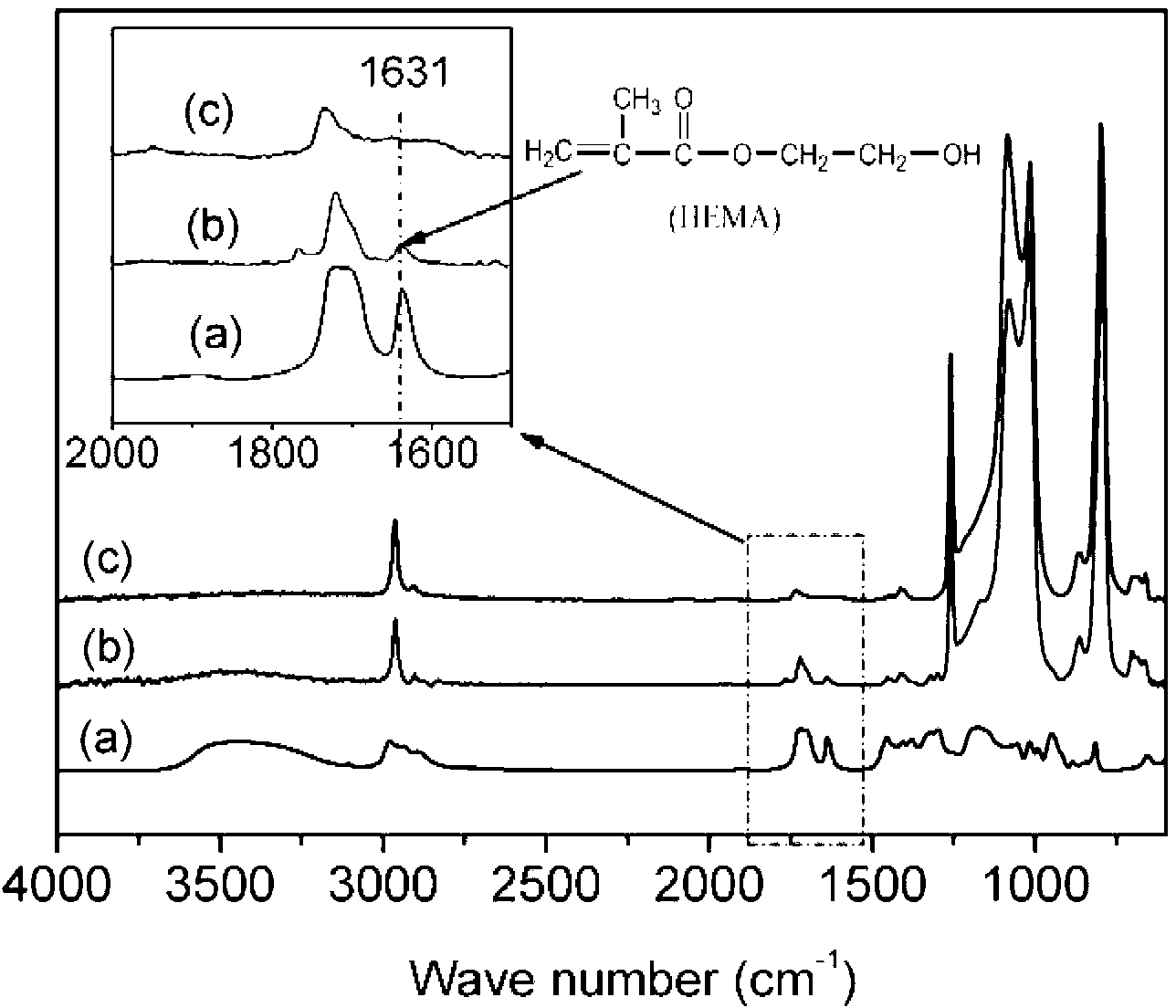

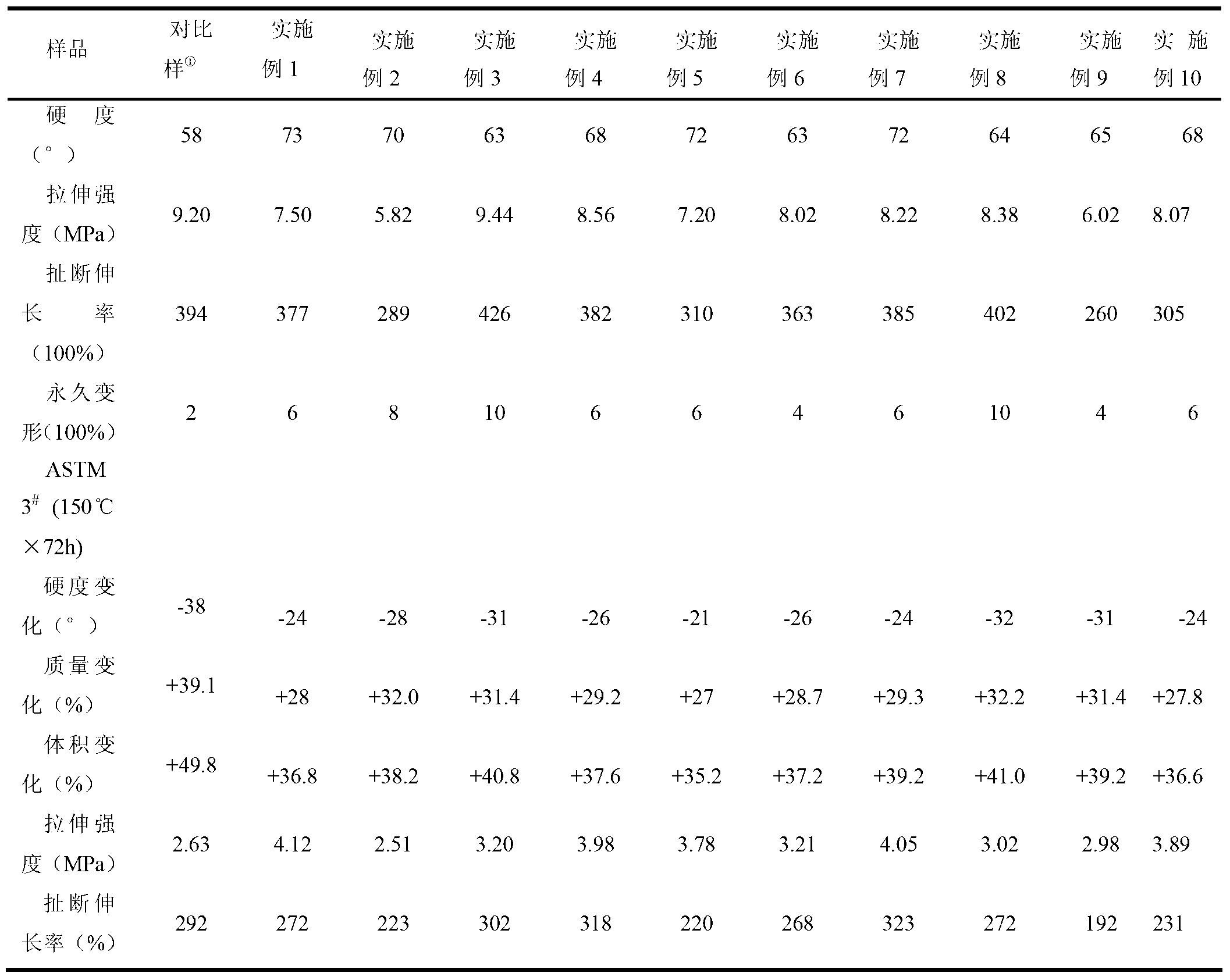

[0018] At room temperature, add 100g methyl vinyl silicone rubber and 40g fumed silica to the open mill and mix for 20 minutes, then add 2g hydroxy silicone oil and mix for 5 minutes, place the obtained silicone rubber mixture for 6 hours, and then add it to In an open mill, add 10g of HEMA into the rubber mix at room temperature. After the HEMA is added, mix for 5 minutes, then add 2g of TBPB and mix for 5 minutes to obtain a silicone rubber mix. Put the mixed rubber in the mold, pressurize and exhaust, press at 145°C for 30 minutes (the in-situ grafting reaction occurs within this period), take it out from the mold, and obtain an oil-resistant silicone rubber material.

Embodiment 2

[0020] At room temperature, add 100g methyl vinyl silicone rubber and 30g fumed silica to the open mill and mix for 10 minutes, then add 1g hydroxy silicone oil and mix for 5 minutes, place the obtained silicone rubber mixture for 24 hours, then add it to In the open mill, add 20g of HEMA into the rubber mixture at room temperature. After the HEMA is added, mix for 10 minutes, then add 2g of BPO and mix for 10 minutes to obtain a silicone rubber mixture. Put the mixed rubber in the mold, pressurize and exhaust, press at 110°C for 60 minutes (the in-situ grafting reaction occurs within this period), take it out from the mold, and obtain an oil-resistant silicone rubber material.

Embodiment 3

[0022] At room temperature, add 100g methyl vinyl silicone rubber and 40g fumed silica to the open mill and mix for 15 minutes, then add 2g hydroxy silicone oil and mix for 5 minutes, place the obtained silicone rubber mixture for 10 hours, and then add it to In the open mill, 5g of HPMA was added to the rubber mix at room temperature. After the HPMA was added, it was mixed for 8 minutes, and then 1g of TBPB was added and mixed for 8 minutes to obtain a silicone rubber mix. Put the mixed rubber in the mold, pressurize and exhaust, press at 140°C for 35 minutes (the in-situ grafting reaction occurs within this period), take it out from the mold, and obtain an oil-resistant silicone rubber material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com