High-speed translational movement parallel mechanism with three degrees of freedom

A technology of translational motion and degree of freedom, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of weak attitude restraint ability and difficult attitude control, and achieve improved ability to resist lateral loads, strong restraint ability, high speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

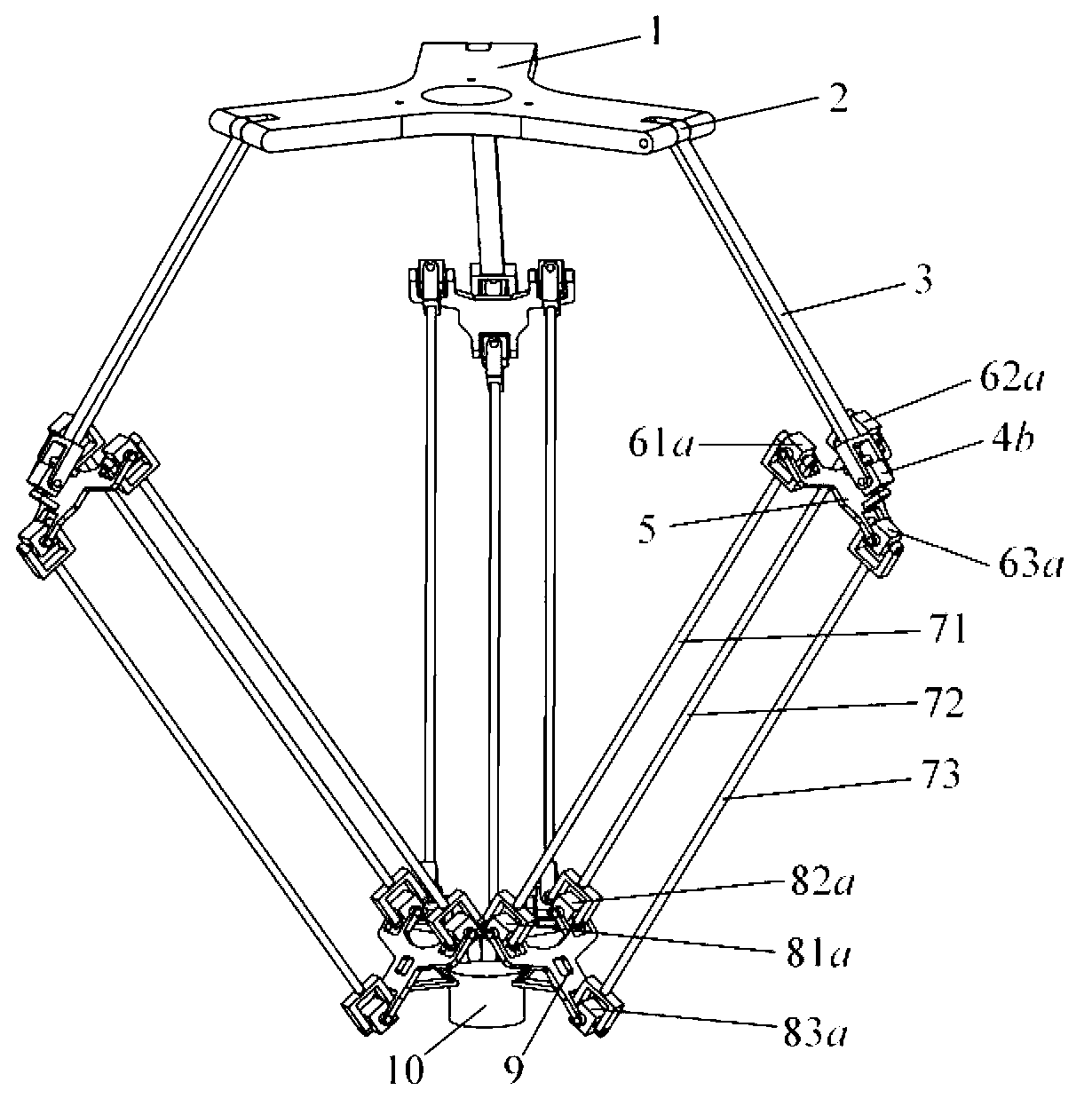

[0018] The overall structure of the three-degree-of-freedom high-speed translational motion parallel mechanism of the present invention is as follows: figure 1 As shown, in addition to the above-mentioned structural features, the axes of the first rotating pair 2 connecting the driving arm 3 and the fixed platform 1 in the three motion branch chains are in a plane and intersect each other to form an equilateral triangle; the driving arm 3 It is connected with the upper connecting plate 5 of the composite sub-chain by the second rotating pair 4a, and the axis of the second rotating pair 4a is parallel to the axis of the first rotating pair 2; the lower connecting plates 9 of the three composite sub-chains are respectively connected with The inclined planes of the three space tetrahedrons evenly distributed in the circumferential direction of the motion platform 10 are directly fixedly connected. Compared with the motion platform 10, the fourth Hooke hinge 81a and the fifth Hooke...

Embodiment 2

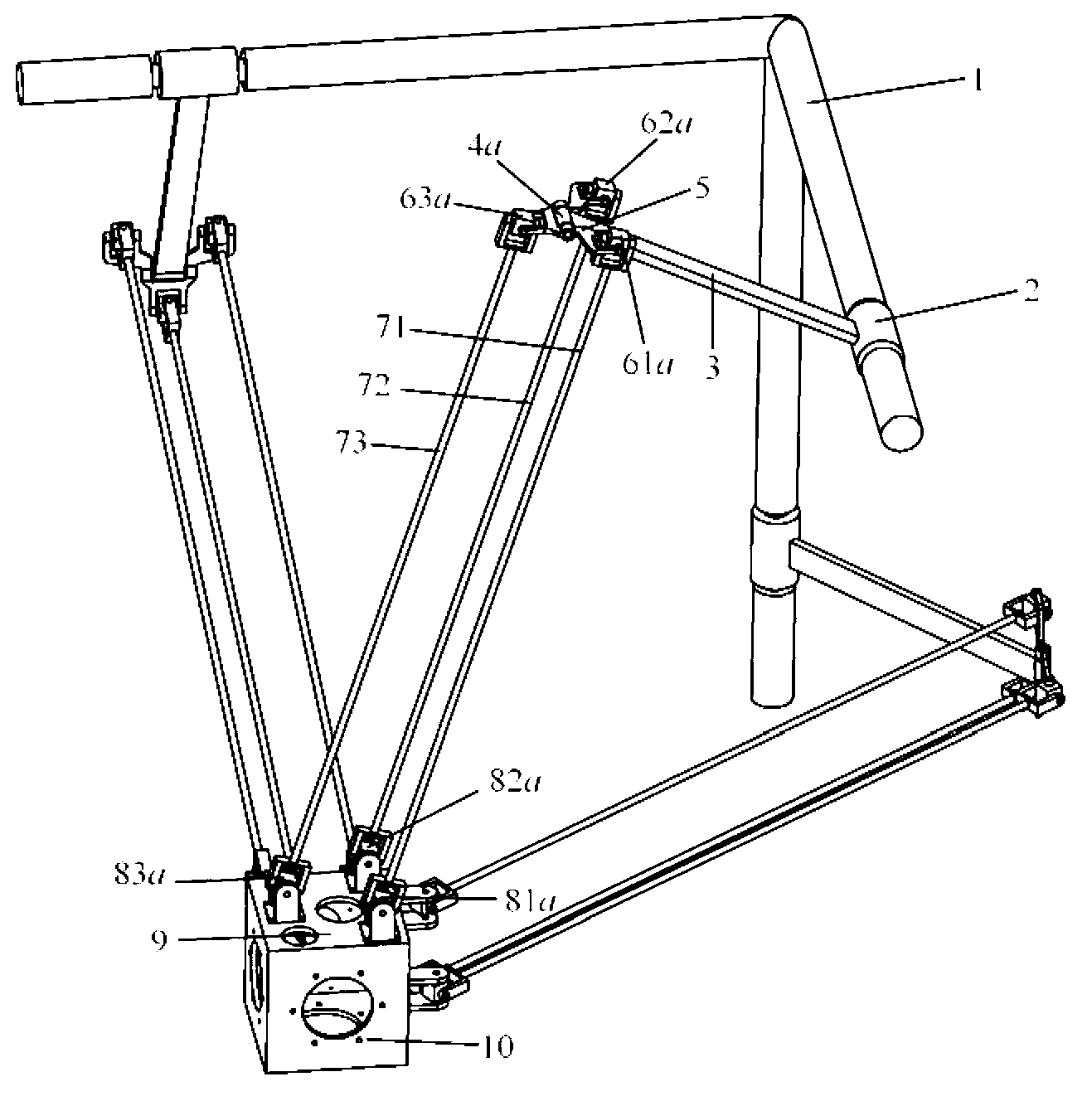

[0020] The general structure of the three-degree-of-freedom high-speed translational motion parallel mechanism of the present invention is as follows: figure 2 As shown, its structure is basically the same as that of the mechanism in Example 1, the only difference is that the driving arm 3 is connected to the upper connecting plate 5 of the composite branch chain through the seventh Hooke hinge 4b, and the seventh tiger connecting the driving arm 3 The axis of the gram hinge 4b is parallel to the axis of the first rotating pair 2 .

Embodiment 3

[0022] The general structure of the three-degree-of-freedom high-speed translational motion parallel mechanism of the present invention is as follows: image 3 As shown, the difference between this mechanism and the mechanism of Embodiment 1 is that the axes of the first rotating pair 2 connecting the driving arm 3 and the fixed platform 1 in the three motion branch chains intersect at one point and are arranged orthogonally to each other; the three compound The lower connection plates 9 of the sub-branches are respectively connected on three mutually orthogonal planes of the motion platform 10. With respect to the motion platform 10, the fourth Hooke hinge 81a and the second connection plate 9 of the three motion branches are connected to the lower connection plate 9. The centers of the five Hooke hinges 82a and the sixth Hooke hinges 83a form a spatial distribution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com