Remanufacturing process of fully-mechanized coal mining hydraulic bracket

A hydraulic support and remanufacturing technology is applied in the field of mining machinery to achieve the effect of improving remanufacturing efficiency, ensuring product quality and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with specific embodiments

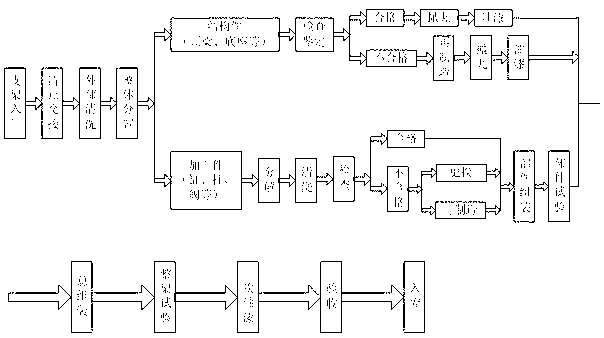

[0021] Such as figure 1 As shown, the fully mechanized mining hydraulic support remanufacturing process includes the following steps:

[0022] 1. Cleaning before dismantling: recycle waste parts, use high-pressure washing machines and semi-closed circulating pools to clean parts, remove coal powder, coal gangue and other sundries on the surface of the bracket, and focus on cleaning the column socket and the front and rear , Coal powder in the upper connecting rod.

[0023] 2. Dismantling: Use a press to disassemble the disassembled waste parts without damage.

[0024] 1) Remove the connecting rod pin and the upper pin of the column, and unfold the bracket;

[0025] 2) Remove the upper connecting rod, front and rear connecting rods, front telescopic beam, rear plate, front telescopic jack, rear tail beam jack, rear plate jack, and push jack. Place it on a wooden pad to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com