Mold for seam trimming of titanium alloy straight pipe and method for machining seam trimming

A trimming die, titanium alloy technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problem that the quality of trimming of titanium alloy straight pipe seams is difficult to guarantee, so as to facilitate welding and ensure cutting The effect of edge quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

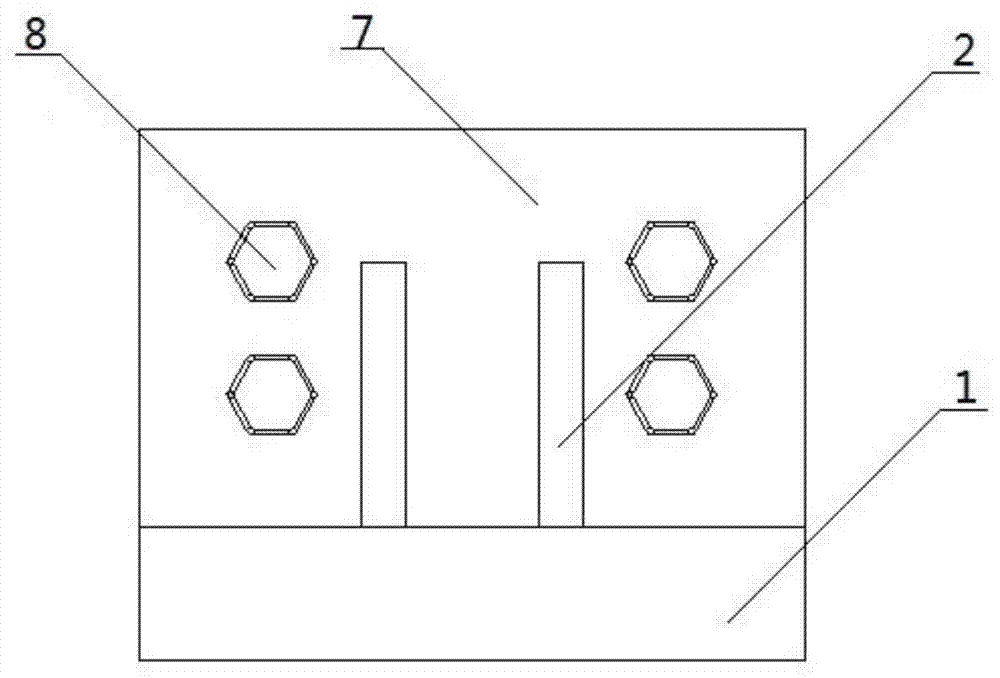

[0028] The following examples refer to Figure 1-8 .

[0029] This embodiment is a mold for trimming a titanium alloy straight pipe with a length of 200mm and a section of Φ60mm, including a base 1 of the trimming mold, a reinforcing rib 2, a splint 3, a mandrel 4, an outer mold 5, and a clamping block 6. Side plate 7, bolt 8. Among them, the splint 3 and the side plate 7 are 40 mm away from the two ends of the base 1, the reinforcing rib 2 is located outside the splint 3 and the side plate 7 and close to the end face of the base 1, the distance between two adjacent reinforcing ribs 2 is 30 mm, and the center plane of the base 1 Symmetrical, the splint 3, side plate 7 and rib 2 are fixed on the base 1 by welding, the clamping block 6 is located between the splint 3 and the side plate 7 and close to the side of the side plate 7, the position is adjustable, and the splint 3 Cooperate with clamping the outer mold 5, use the mandrel 4 to open the straight pipe piece into the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com