Dedicated core of multipath hydraulic control main body valve for manufacturing heavy duty excavator

An excavator and mud core technology, which is applied in the field of special mud cores, can solve problems such as high dimensional accuracy requirements, complex internal structures of hydraulic castings, and no literature reports on valve bodies, and achieve the effect of improving combination accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The mud core of the present invention is a ZYW-J28-2-1 valve body which is a special mud core for a multi-channel control valve body for a 20-ton excavator.

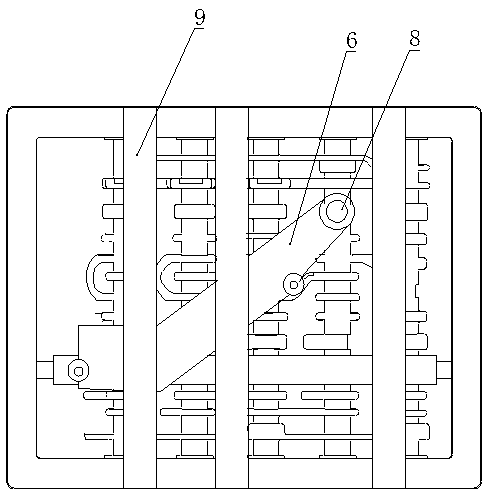

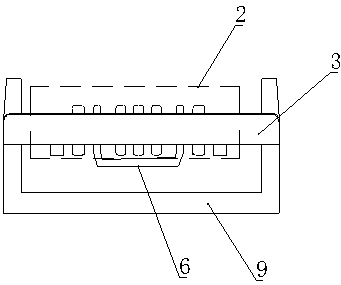

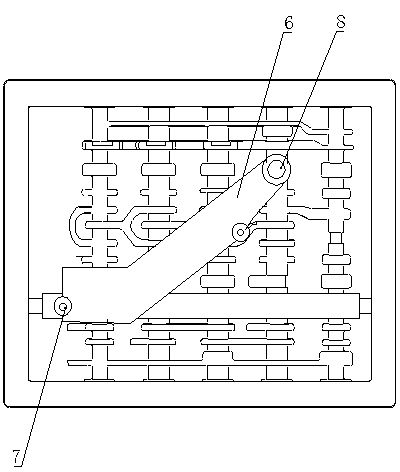

[0027] Such as figure 1 , 2 As shown in, 3 and 4, the main body valve mud core is three-layer multi-channel. The mud core 1 of the upper main body valve is integrally formed from the sheet mud core 2 through the strip core head 3 according to the casting flow channel distribution structure, and then mutually positioned by the core head 3; the core heads 3 are connected end to end to form a square structure.

[0028] The details are as follows: The structure of the sheet-shaped mud core 2 is: five main mud cores 4 and a branch flow channel 5 between the main mud cores 4 are connected. The strip core 3 is a long strip, surrounds the outer edge of the main mud core 4, surrounds it in a square in the circumferential direction, and is connected and positioned at the end of the mud core inside to form a whole. Such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com