Water-cooled gas laser tube

A gas laser, water-cooled technology, used in gas laser parts, laser parts and other directions, can solve the problems of fragile customers, loss, inconvenient recycling and reuse, and achieve the effect of solid overall structure and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

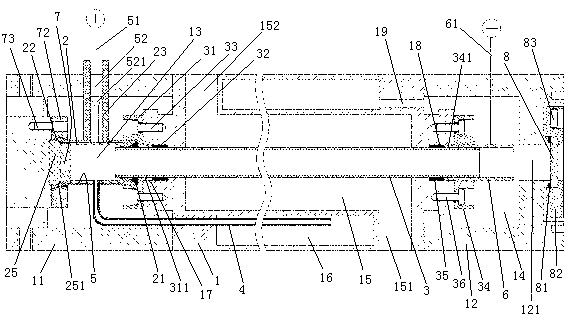

[0019] Embodiment one, see figure 1 , an air-cooled gas laser tube, including a support frame 1, a discharge tube 3, an anode 5, a cathode 6, a mirror 7 and an output mirror 8.

[0020] The support frame 1 is made of metal material. The support frame 1 is a straight rod-shaped structure. The left end of the support frame 1 is provided with an anode cover 11 , and the right end of the support frame 1 is provided with a cathode cover 12 . The cathode cover 12 and the support frame 1 enclose a cathode chamber 14 . Both the anode cover 11 and the cathode cover 12 are made of metal materials. An anode chamber 13 surrounded by an insulating sleeve 2 and an insulating cover 25 is provided in the space enclosed by the anode cover 11 and the metal support frame 1 .

[0021] The support frame 1 is provided with a cooling chamber 15 and an air storage chamber 16 . The cooling chamber 15 extends in the left-right direction. The right end of the cooling chamber 15 is provided with a ...

Embodiment 2

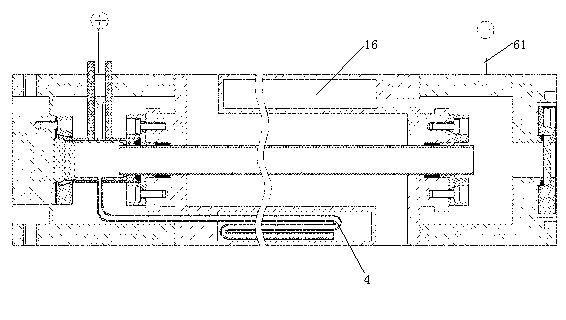

[0040] Embodiment two, see figure 2 , the difference with Embodiment 1 is:

[0041] In order to prolong the time for the laser gas to flow back into the discharge tube 3, so that the laser gas can have sufficient time to regenerate and recover, the part of the gas return pipe 4 located in the gas storage chamber 16 is designed in a circuitous and bent structure. The cathode is not designed, but the cathode power line 61 is directly electrically connected to the cathode cover 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com