Packaging method of organic electronic device

A technology of organic electronic devices and packaging methods, applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems that rigid packaging cannot meet the packaging requirements of flexible devices, and achieve the goal of improving service life, reducing costs, and reducing thermal damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

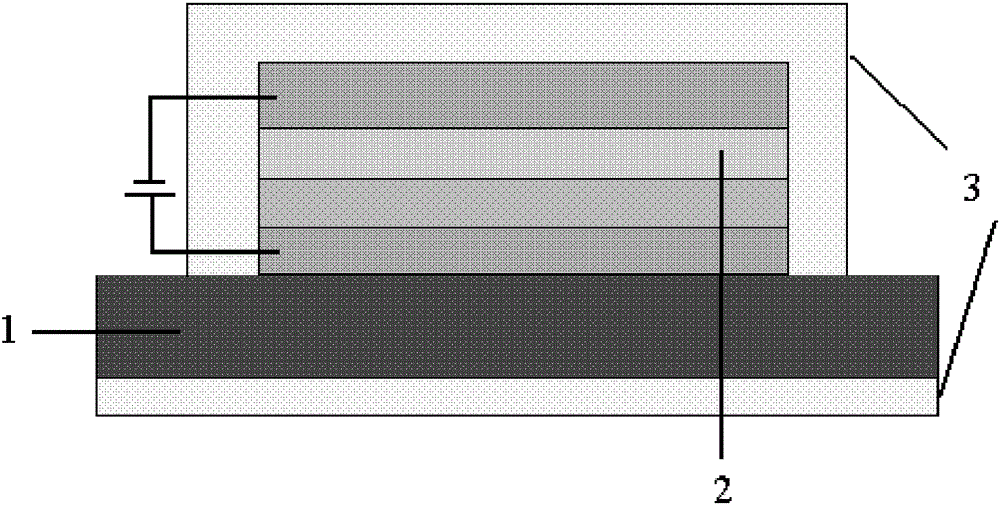

[0021] Such as figure 1 As shown, the packaging method for organic electronic devices provided by the present invention is divided into two steps: a pre-process and a post-process.

[0022] The pre-process is that before the organic electronic device 2 is fabricated, a multilayer composite film 3 is first deposited on the back of the substrate 1 material. A plasma enhanced chemical vapor deposition method (hereinafter referred to as a PECVD method) is used to deposit a multilayer composite film 3. The multilayer composite film 3 is composed of several stacked layers of alternating organic layers and inorganic layers. The organic layer is made of organic polymers, including: parylene, polypropylene, polyacrylate or silicone cross-linked polymer SiO x C y H z . It is used to isolate water and oxygen; the inorganic layer is an inorganic substance, which is used to increase flexibility, bend and prevent fracture. The inorganic layer is made of inorganic materials, including: SiN x...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com