Self-healing capacitor element

A technology of self-healing capacitors and components, applied in the direction of capacitors, electrical components, etc., can solve problems such as capacitors can no longer restore insulation, capacitors catch fire, burn capacitors, etc., to eliminate self-healing failures, improve self-healing performance, reduce electrical damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

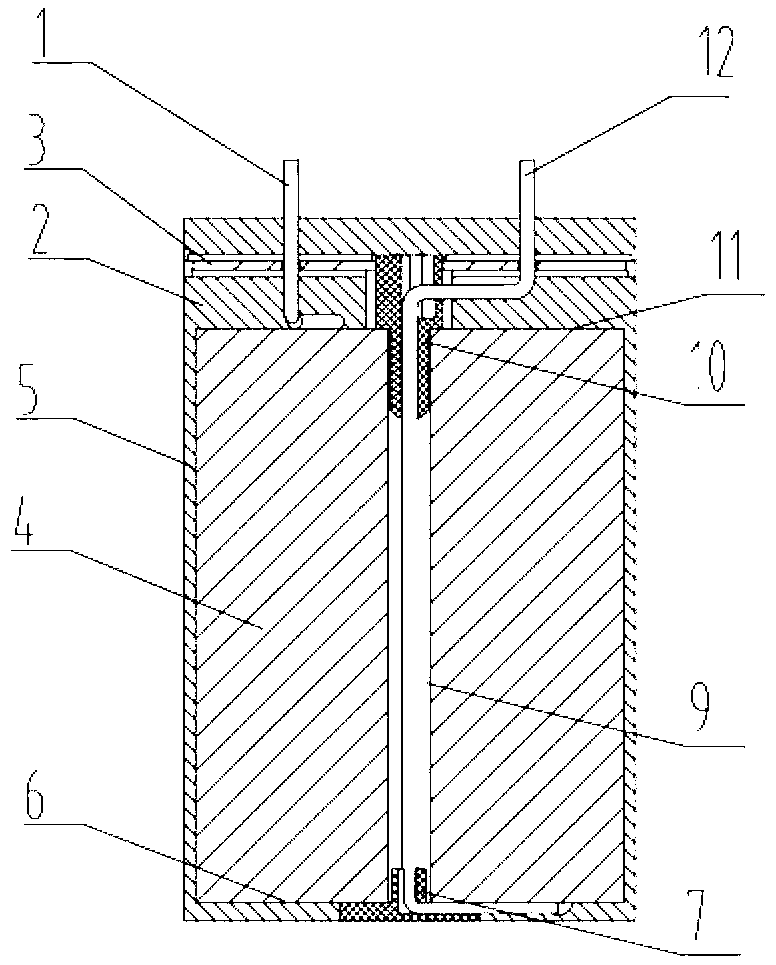

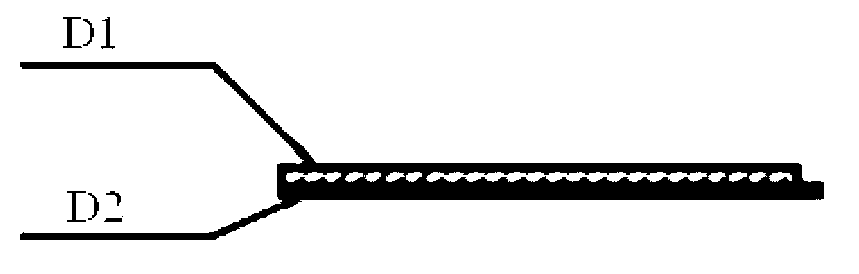

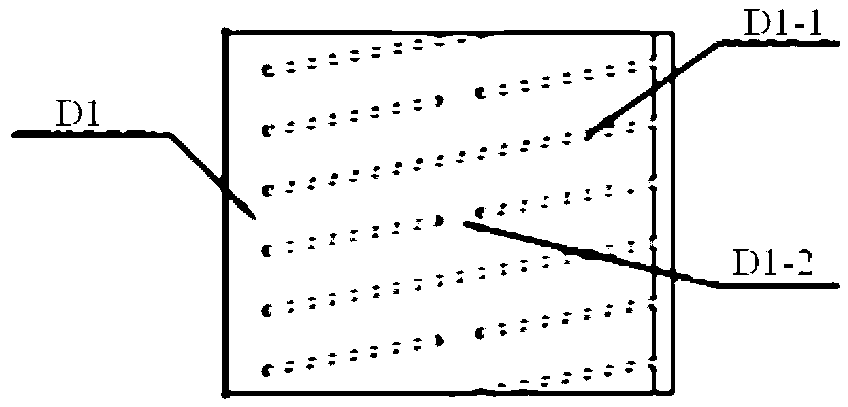

[0019] refer to figure 1 , the capacitor element has a plastic shell 5, which has a cylinder 4 wound by two layers of metallized film, one layer of the metallized film is a flat metallized film, and one layer is an isolated metallized film, and the cylinder There is a hollow pipe 9 in the middle of 4. Both ends of the cylinder 4 are sprayed with a gold spraying machine to form an upper metal layer 11 and a lower metal layer 6, the first electrode 1 is welded to the upper end of the cylinder 4, and the second electrode 12 is welded to the lower end of the cylinder 4 through the hollow tube 9 , the first plunger 7 and the second plunger 10 are fixed at both ends of the hollow tube 9, both of which have the function of positioning and insulating between electrodes, and the isolation type metallized film is a single string type. Cylindrical components, electrodes, are fixed in the housing 5 through the upper bracket 3, and then the interior of the plastic housing 5 is filled with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com