Ultrasonic wave sensor for improving sensitivity through wire stripping process

An ultrasonic and sensor technology is applied in the field of ultrasonic sensors to achieve the effect of increasing the vibration amplitude, saving raw materials and production processes, and preventing intermittent non-working or non-working.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

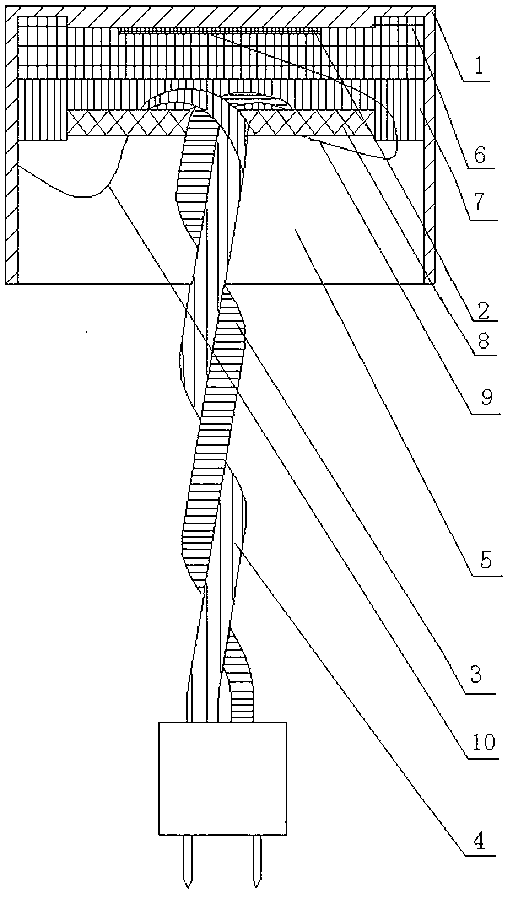

[0045] Embodiment one: if figure 2 As shown, an ultrasonic sensor with wire stripping treatment to improve sensitivity includes a cylindrical shell, a piezoelectric element, a positive signal output line, a negative signal output line, a first sealant layer, and a sound-absorbing element layer. One end of the cylindrical shell is closed It is the bottom end surface of the cylindrical shell, and the inner wall of the bottom end surface of the cylindrical shell is provided with a boss. The end face is welded, one end of the signal output negative line is welded to the inner side wall of the cylindrical shell, the lower end face of the sound-absorbing element layer covers the other end face of the piezoelectric element, the inner bottom end face of the cylindrical shell, and the inner wall of the cylindrical shell, the first The sealant layer seals the concave groove formed between the upper end surface of the sound-absorbing element layer and the inner wall of the cylindrical s...

Embodiment 2

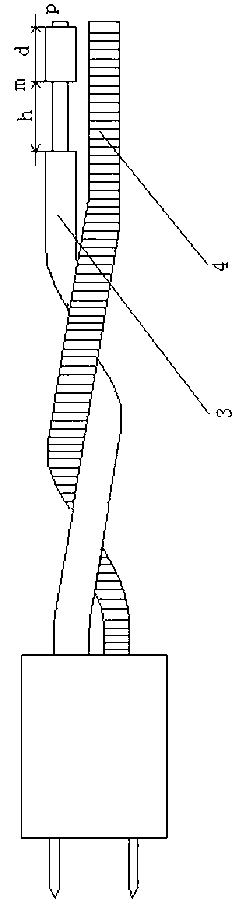

[0046] Embodiment two: if image 3 As shown, on the basis of Example 1, the range of d is 0.5 mm to 5 mm, the range of h is 0.5 mm to 3 mm, and the amplitude of the ultrasonic sensor is as described in Table 2.

Embodiment 3

[0047]Embodiment 3: On the basis of Embodiment 2, the d is 1.5 mm to 3 mm, the h is 0.5 mm to 3 mm, and the amplitude of the ultrasonic sensor is as described in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com