Bearing capacity detection device for tunnel fan support structure

A detection device and supporting structure technology, applied in the testing of machine/structural components, measuring devices, testing of mechanical components, etc., can solve the problems of unreliable loading results, cumbersome supporting equipment, troublesome installation, etc., to ensure reliability and reliability. Stability, low cost, convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

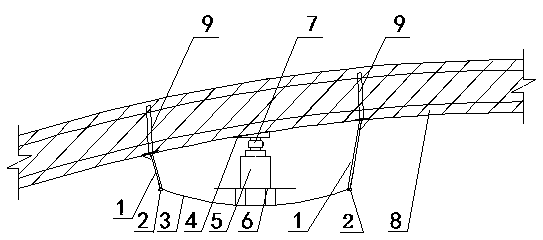

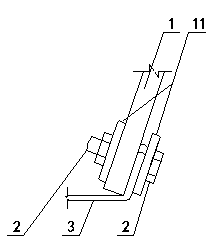

[0043] see Figure 1 to Figure 4 The bearing capacity detection device for the support structure of the tunnel fan includes a steel wire rope group composed of several steel wire ropes 3 arranged side by side; 9 is connected; the middle part of the steel wire rope group is placed with a steel plate base 6, the steel plate base 6 is provided with a jack 5, the jack 5 is provided with a column load cell 7, and the top of the column load cell 7 is connected to the tunnel Lining 8 contacts.

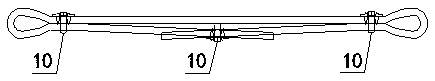

[0044] Wherein, both ends of the steel wire rope 3 are connected to the hoisting plate 1 through a connecting screw 2 ; steel gaskets 11 are provided between the connecting screw 2 , the steel wire rope 3 and the hoisting plate 1 . The wire rope 3 is provided with a wire rope clip 10 . The wire rope clamp 10 is a U-shaped rope clamp. The steel pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com