Etching method and etching polishing liquid

A technology of polishing liquid and etching liquid, which is applied in the field of etching and polishing liquid, can solve problems such as poor connection effect, lack of transition, poor visual and tactile effects of microstructure, etc., and achieve the effect of easy control, good transition and good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

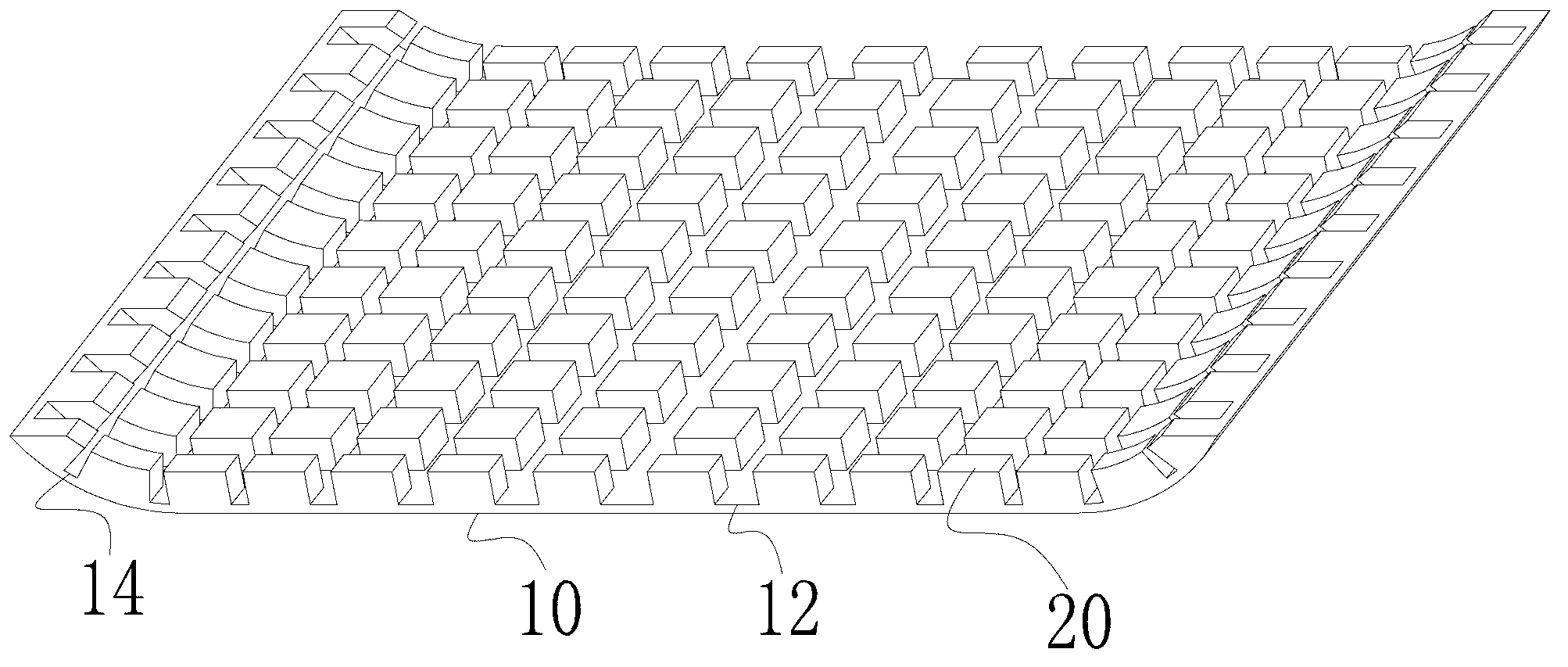

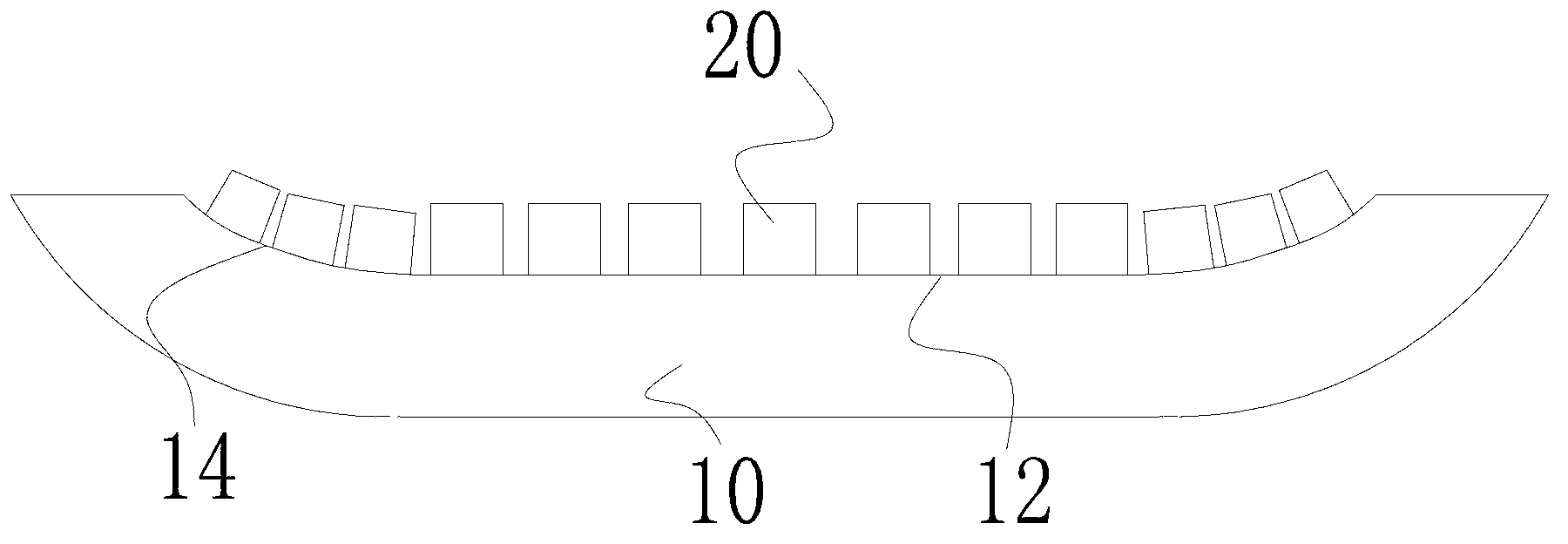

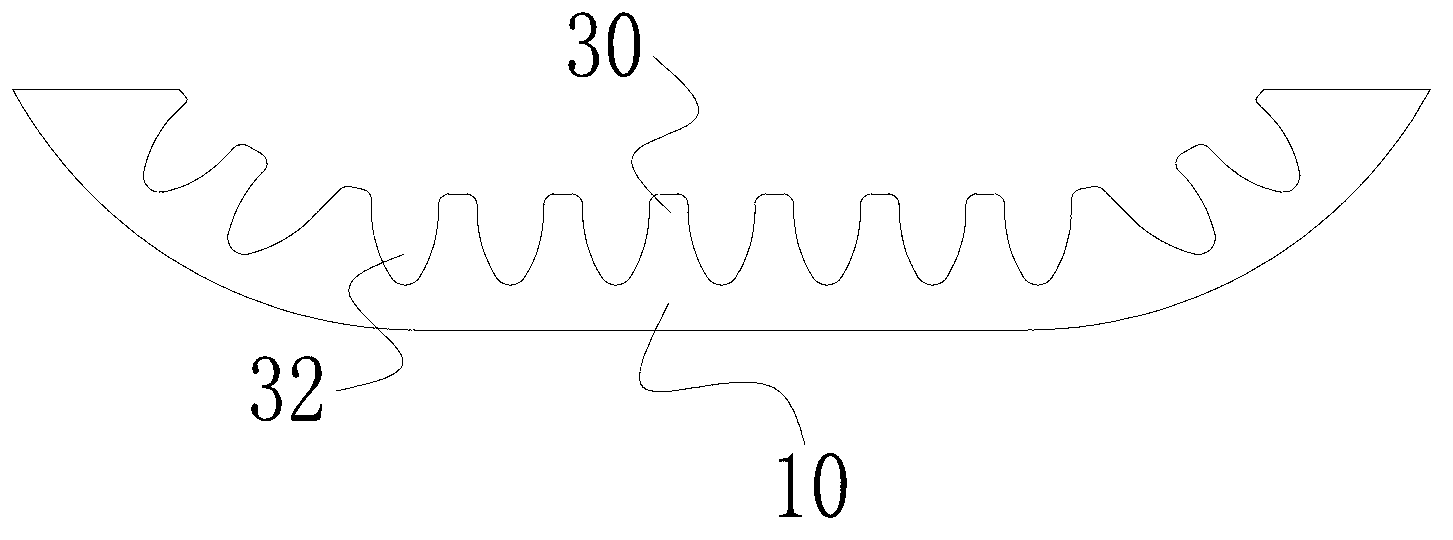

[0029] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] An etching method of the present invention is used for etching the surface of a metal product having a plane and an arc-shaped curved surface connected to the plane, comprising the following steps:

[0031] (1) Masking treatment: Coating a plurality of square mask blocks on the plane and curved surface of the metal product. The side lengths of the mask blocks on the plane are uniform in size. The side length is smaller than the mask block on the plane, and the side length of the mask block on the curved surface gradually decreases from the connection between the plane and the curved surface to the edge of the curved surface, and the gap between two adjacent mask blocks is the mask Gap, the mask gap gradually decreases from the center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com