Method for extracting natural acid-pickling corrosion inhibitor from surplus sludge and application thereof

A technology of excess sludge and corrosion inhibitor, which is applied in the field of environmental protection, comprehensive utilization of resources and surface of metal materials, can solve problems such as application restrictions and environmental pollution, and achieve simple and easy operation, wide source of raw materials, and simple and easy extraction method line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

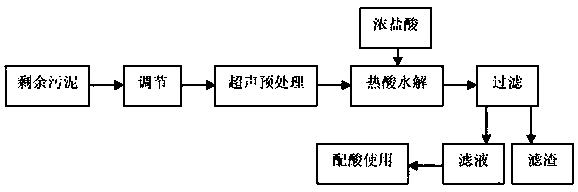

Method used

Image

Examples

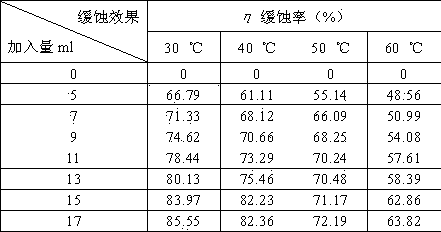

preparation Embodiment 1

[0021] The remaining sludge comes from the secondary settling tank of the urban domestic sewage treatment plant. The properties of the sludge are as follows: the moisture content of the remaining sludge is 96.0% (wt.), MLSS is 40.0 g / L, and MLVSS is 27.2 g / L. Before sludge hydrolysis, ultrasonic pretreatment was used to destroy the floc structure of sludge. The working conditions of the ultrasonic reactor were: pretreatment time 90 minutes, ultrasonic frequency 40 kHz. Take 100ml of the pretreated sludge and put it in a stoppered glass container, add 12ml of concentrated hydrochloric acid (37.0% wt.), seal it with a plastic film and place it in a constant temperature water bath for heating and hydrolysis. The hydrolysis temperature is 70±0.5°C. The hydrolysis time is 22 hours. After hydrolysis, the insoluble residue is removed by filtration, and the obtained reddish-brown transparent liquid is the corrosion inhibitor. The amino acid concentration in the obtained solution measur...

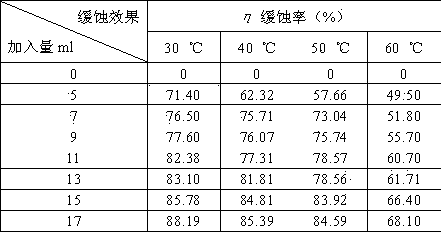

preparation Embodiment 2

[0023] The remaining sludge comes from the secondary settling tank of the urban domestic sewage treatment plant. The properties of the sludge are as follows: the moisture content of the remaining sludge is 97.0% (wt.), MLSS is 30.0 g / L, and MLVSS is 18.9 g / L. Before sludge hydrolysis, ultrasonic pretreatment was used to destroy the floc structure of sludge. The working conditions of the ultrasonic reactor were: pretreatment time 90 minutes, ultrasonic frequency 40 kHz. Take 100ml of pretreated sludge and put it in a glass container with a stopper, add 12ml of concentrated hydrochloric acid (37.0% wt.), seal it with a plastic film and place it in a constant temperature water bath for heating and hydrolysis. The hydrolysis temperature is 90±0.5°C. The hydrolysis time is 14 hours. After hydrolysis, the insoluble residue is removed by filtration, and the obtained reddish-brown transparent liquid is the corrosion inhibitor. The amino acid concentration in the obtained solution measu...

preparation Embodiment 3

[0025] The remaining sludge comes from the secondary settling tank of the urban domestic sewage treatment plant. The properties of the sludge are as follows: the moisture content of the remaining sludge is 98.0% (wt.), MLSS 20.0 g / L, and MLVSS 12.6 g / L. Before sludge hydrolysis, ultrasonic pretreatment was used to destroy the floc structure of sludge. The working conditions of the ultrasonic reactor were: pretreatment time 90 minutes, ultrasonic response frequency 40 kHz. Take 100ml of pretreated sludge into a glass container with a stopper, add 10ml of concentrated hydrochloric acid (37.0% wt.), seal it with a plastic film, and place it in a constant temperature water bath for heating and hydrolysis. The hydrolysis temperature is 100±0.5°C. The hydrolysis time is 18 hours. After hydrolysis, the insoluble residue is removed by filtration, and the obtained reddish-brown transparent liquid is the corrosion inhibitor. The amino acid concentration in the obtained solution measured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com