Method for recovering hydrogen from tail gas of chlorate electrolysis

A technology of chlorate electrolysis and tail gas recovery, which is applied in the field of fine chemical hydrogenation, which can solve the problems of poor use of deoxidation catalyst, poor quality of recovered hydrogen, and non-continuous recovery, so as to achieve better oxygen removal effect and ensure safe production , The effect of eliminating chlorine pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

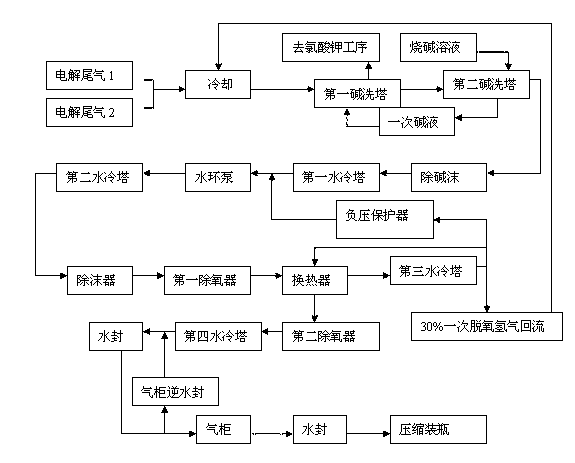

Image

Examples

Embodiment 1

[0044] Adopt process of the present invention to process the electrolysis tail gas of a certain factory, the relevant data before and after treatment are shown in Table 1 (both volume content):

[0045]

[0046] Table 1

[0047] It can be seen from Table 1 that it can meet the relevant requirements of the national standard first-class industrial hydrogen.

Embodiment 2

[0049] A furfuryl alcohol Co., Ltd. in Xingtai is an enterprise that hydrogenates furfural to produce furfuryl alcohol. It needs a large amount of high-quality hydrogen and relies on electrolysis of water to produce hydrogen, which is costly. Later, it was decided to adopt the process of the present invention to thoroughly control the electrolysis tail gas, reclaim valuable H 2 resources to achieve zero exhaust emissions. The process of the present invention has been implemented since May 2001, and has been put into trial operation in January 2002. The whole process equipment runs smoothly, the workers are easy to operate, and a total of 6 million Nm of hydrogen is recovered. 3 , It has created better economic benefits for the enterprise, and also completely changed the environment, and achieved better social benefits.

[0050] We sent the above-mentioned recovered hydrogen to the Henan Provincial Bureau of Quality and Technical Supervision for testing (designated nationwide)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com