Molding equipment capable of manufacturing cement flues with various sizes

A molding equipment and cement technology, applied in the direction of unloading devices, molds, manufacturing tools, etc., can solve the problems of reducing economic benefits, limiting the application range of cement flues, and being unable to adjust the size, so as to reduce labor intensity and shorten production time. , the effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

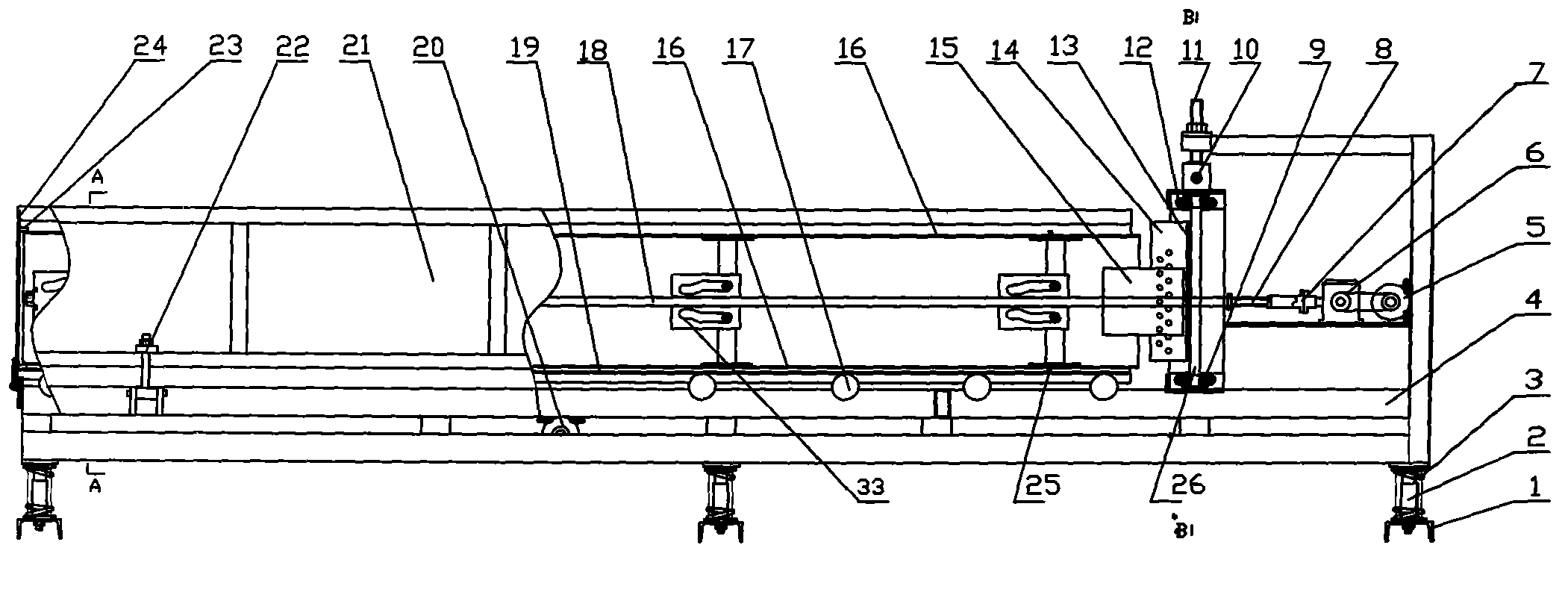

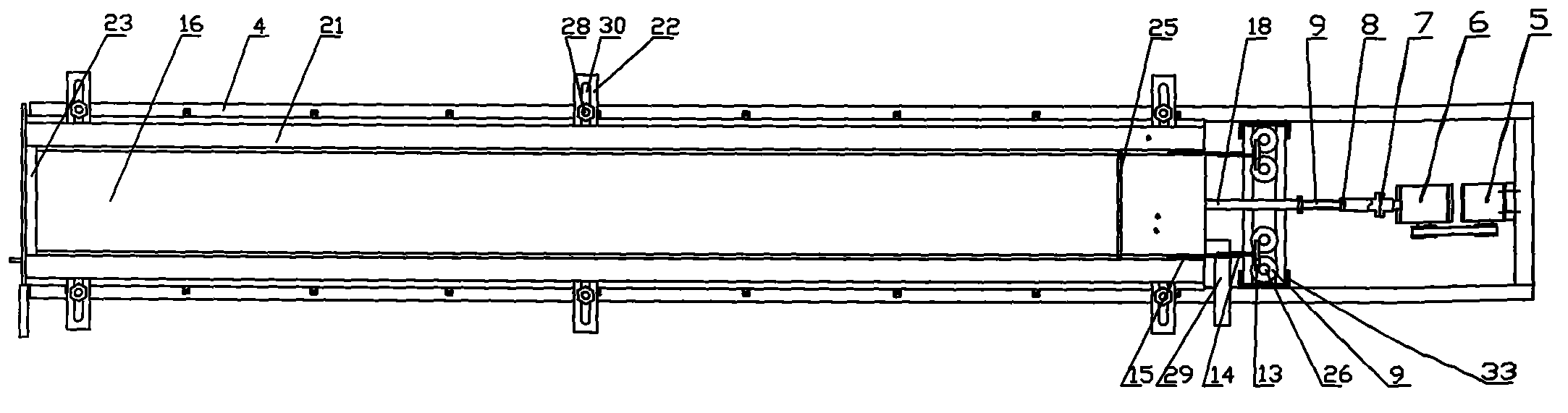

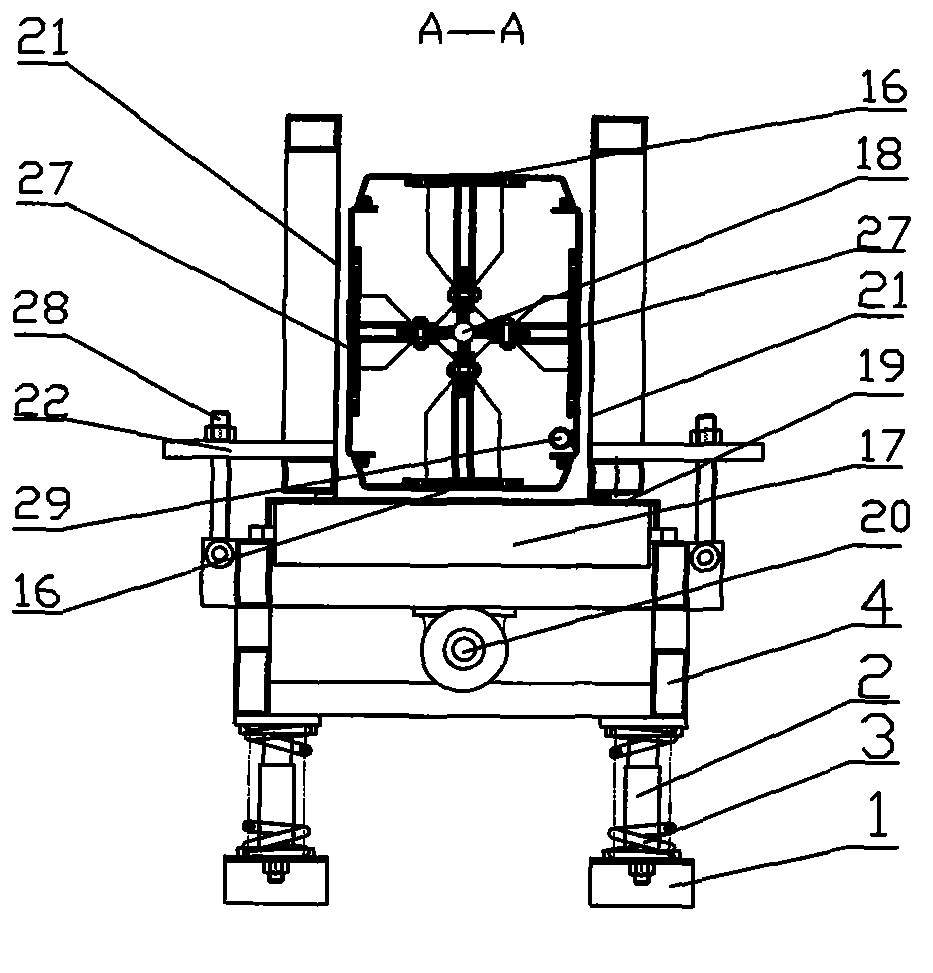

[0024] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, one machine produces various specifications of cement flue molding equipment, including a base 1, a frame 4 is connected to the base 1 through an elastic support device, a vibrator 20 is installed in the middle of the frame 4, and the machine A plurality of rollers 17 are horizontally evenly distributed on the upper surface of the frame 4, and the bottom template 19 that can slide laterally along the rollers 17 is supported on the rollers 17. The two sides of the frame 4 are respectively hinged with outer templates 21, and the outer The template 21 is provided with an outside template width adjustment device; the front portion of the frame 4 is provided with an internal mold height adjustment device, and the internal mold height adjustment device includes a gantry 31 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com