Automatic CNC Jump Cutting Machine

A fully automatic, jump cutting technology, applied in metal processing and other directions, can solve the problems of low speed, inconvenient operation, poor stability, etc., and achieve the effect of high speed, low cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

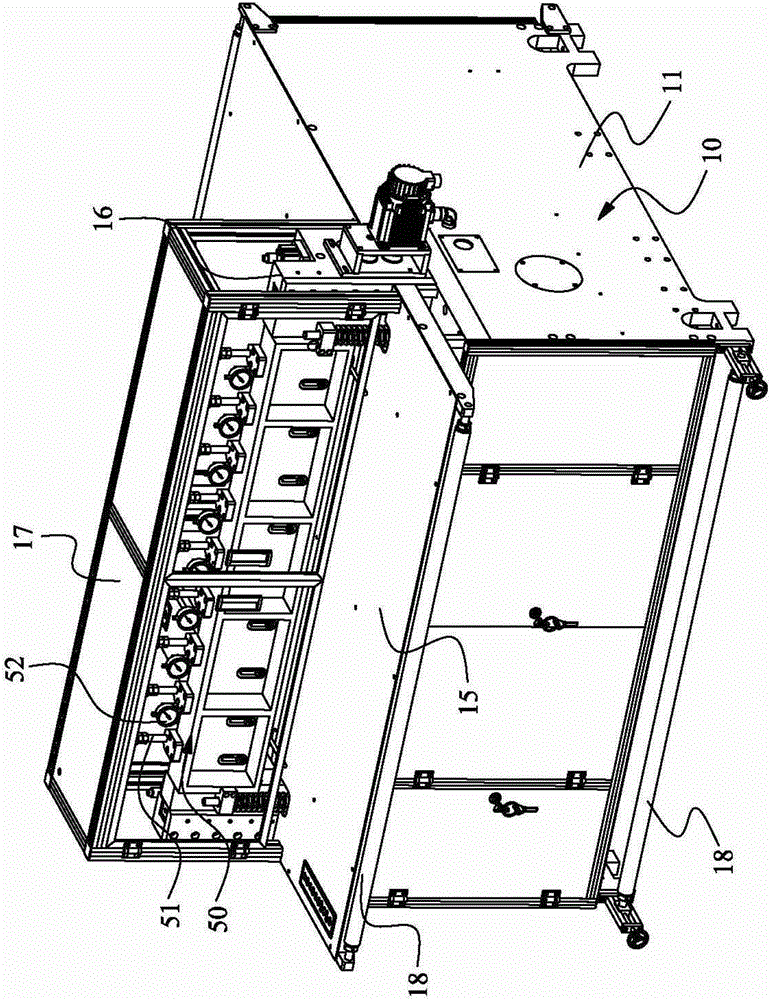

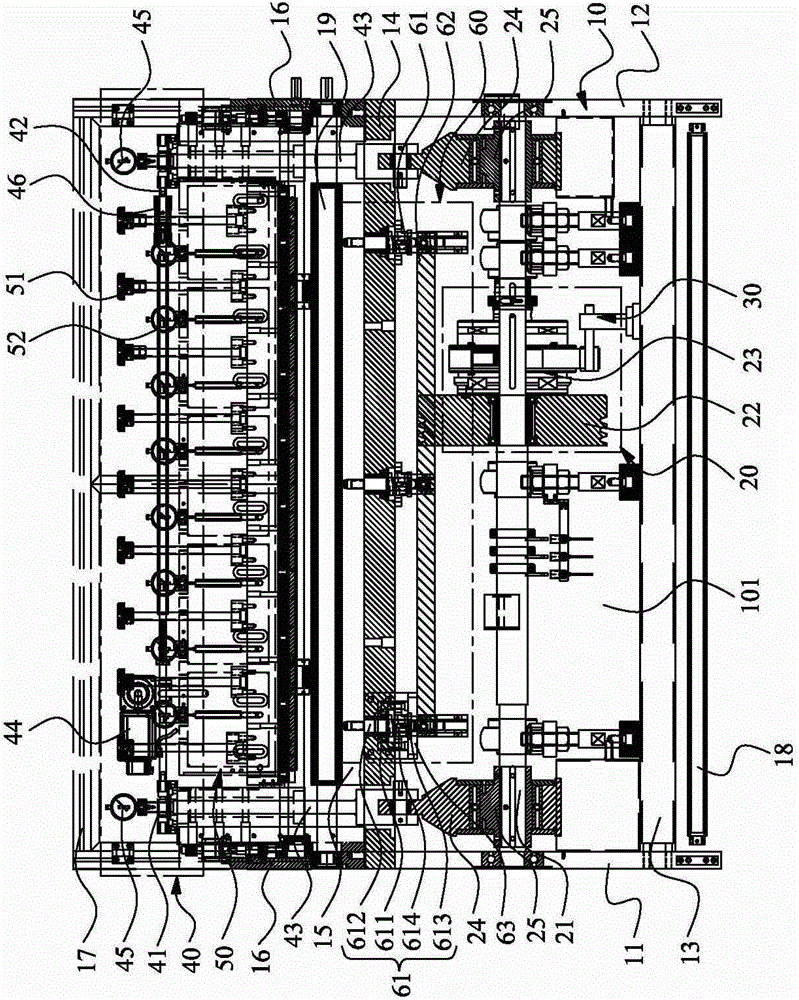

[0052] Please refer to Figure 1 to Figure 6 As shown, it shows the specific structure of the preferred embodiment of the present invention, including the organic body 10, the transmission mechanism 20, the main motor 30, the pressing mechanism 40 and the upper mold base 50.

[0053] Wherein, the machine body 10 includes a left wallboard 11, a right wallboard 12, a support rod 13 and a base plate 14, the support rod 13 is connected between the lower end of the left wall board 11 and the lower end of the right wall board 12, and the base plate 14 is connected Between the upper end of the left wallboard 11 and the upper end of the right wallboard 12, a jumper cutting platform 15 is arranged on the surface of the bottom plate 14, which is composed of the left wallboard 11, the right wallboard 12, the support rod 13 and the bottom plate 14. A containing space 101 .

[0054] The transmission mechanism 20 is located in the aforementioned accommodating space 101. The transmission me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com