Modularized robot kit

A robot and modular technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of large screw connections, cumbersome and time-consuming disassembly and assembly of robots, and achieve the effect of convenient and efficient connection and saving time-consuming man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

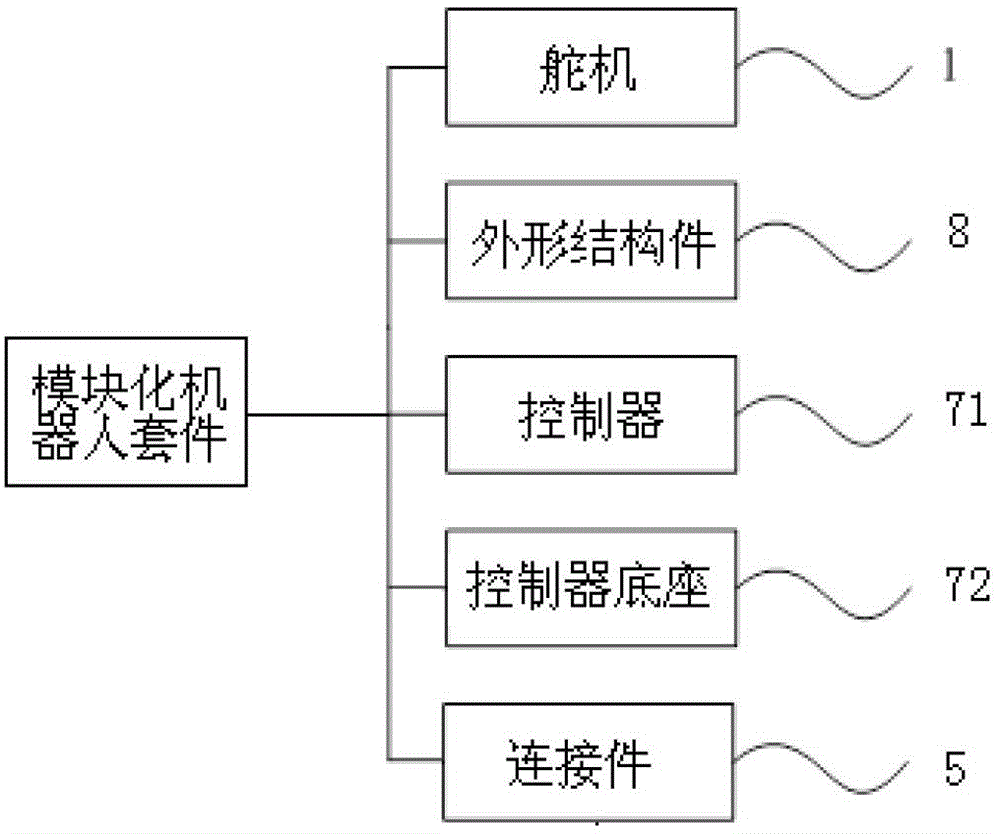

[0049] like figure 1 A preferred embodiment of the invention is shown. In this embodiment, the modular robot kit includes at least one steering gear 1 , at least one external structural part 8 , at least one connecting part 5 , at least one controller 71 and at least one controller base 72 . like figure 2 and image 3As shown, at least one surface of the steering gear 1 and the external structural member 8 is respectively provided with socket slots 11 and 81 , which can fix the steering gear 1 or the connecting piece 8 to the connecting piece. Understandably, as image 3 The structural shape of the shown structural parts is just an example, and other designs are also possible, as long as it includes a socket slot that can be plugged in, it is applicable. The controller 71 as Figure 4 As shown, the controller base is as Figure 5 As shown, the structure of the bottom surface of the controller 71 and the top surface of the controller base correspond to each other so as t...

Embodiment 2

[0057] Combine below Figure 12 Another preferred embodiment of the present invention will be described. The difference of the modular robot kit in this embodiment is that it uses half of the I-shaped buckle cover 3 to connect the steering gear 1 and the external structure 8, and can apply the quick connection of the single-ended output mode, and the remaining components in the kit are in It has been described in Embodiment 1, so it will not be repeated here. As mentioned above, the bottom surface and the side structure of the half I-shaped buckle cover 3 are exactly the same as the buckle cover 2, so it can be fixedly connected with the steering gear output disk 12 in exactly the same way as the buckle cover 2. The half-I-shaped block 31 on the upper surface of the half-I-shaped buckle cover 3 can be fixedly connected with the external structure 8 . Through the quick connection of the single-ended output mode, the rotational torque output by the steering gear 1 can be outpu...

Embodiment 3

[0059] Combine below Figure 13 Another preferred embodiment of the present invention will be described. The difference of the modular robot kit in this embodiment is that it also includes a U-shaped piece 6, a driven plate 4 and two buckle covers 2, which can realize the quick connection of double-ended output mode, and the remaining components in the kit It has been described in Embodiment 1 and will not be repeated here. In this embodiment, the driven disc 4 cooperates with the bearing 131 in the cylindrical boss 13 of the steering gear 1 through a cylindrical pin 43 in the center. The driving plate 4 corresponds to the steering gear output plate 12, and the two sides of the U-shaped piece 6 are respectively aligned with the driven plate 4 and the steering gear output plate 12, so that the insertion pin 21 of the buckle cover 2 penetrates into the U-shaped piece 6. Inserting hole 61, and respectively penetrate the inserting hole 41 of driven plate 4 and the inserting hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com