Clamp

A fixture and slider technology, applied in the field of machinery, can solve the problem that the fixture is not universal, and achieve the effect of rotation and horizontal and vertical movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

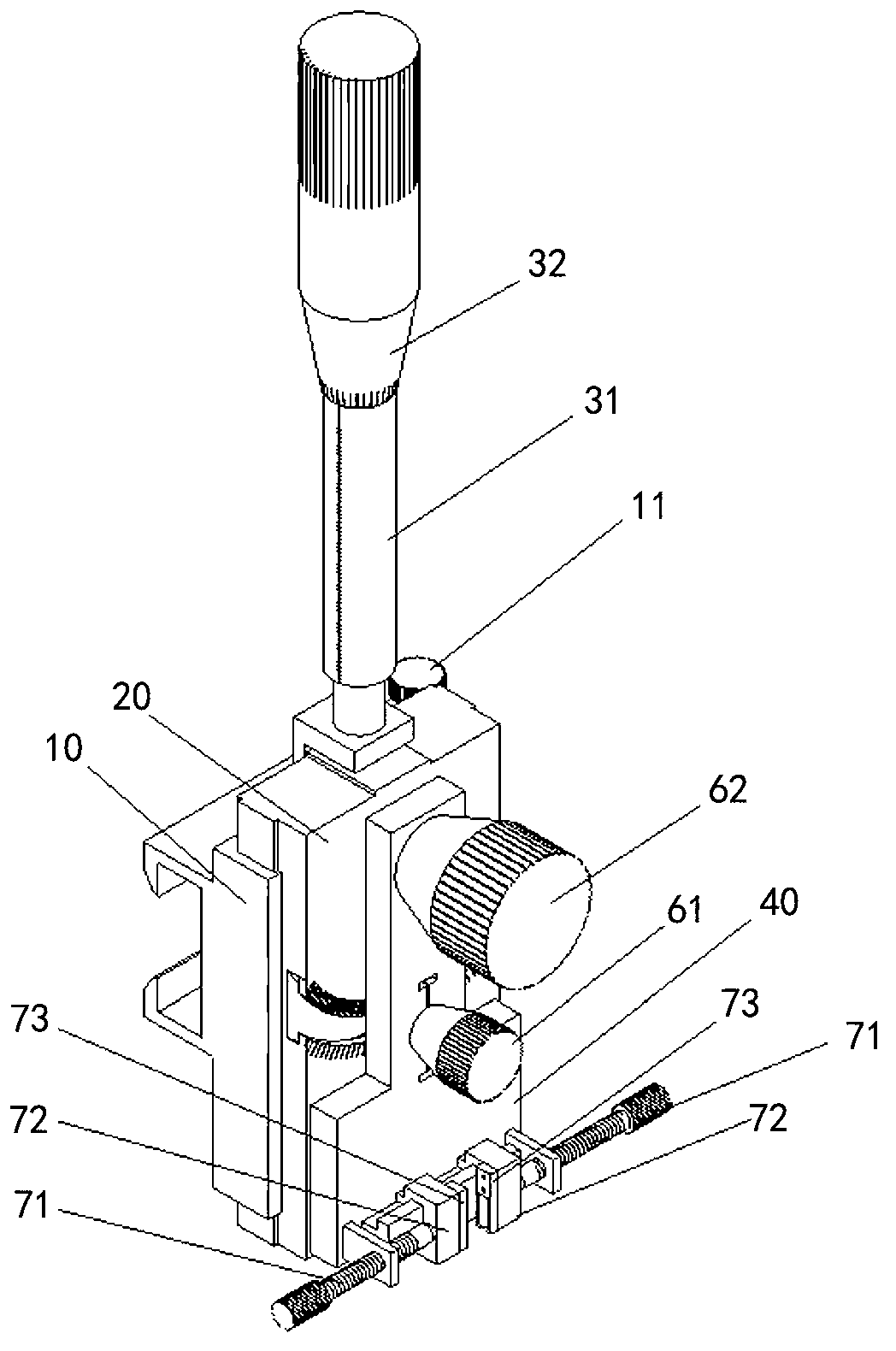

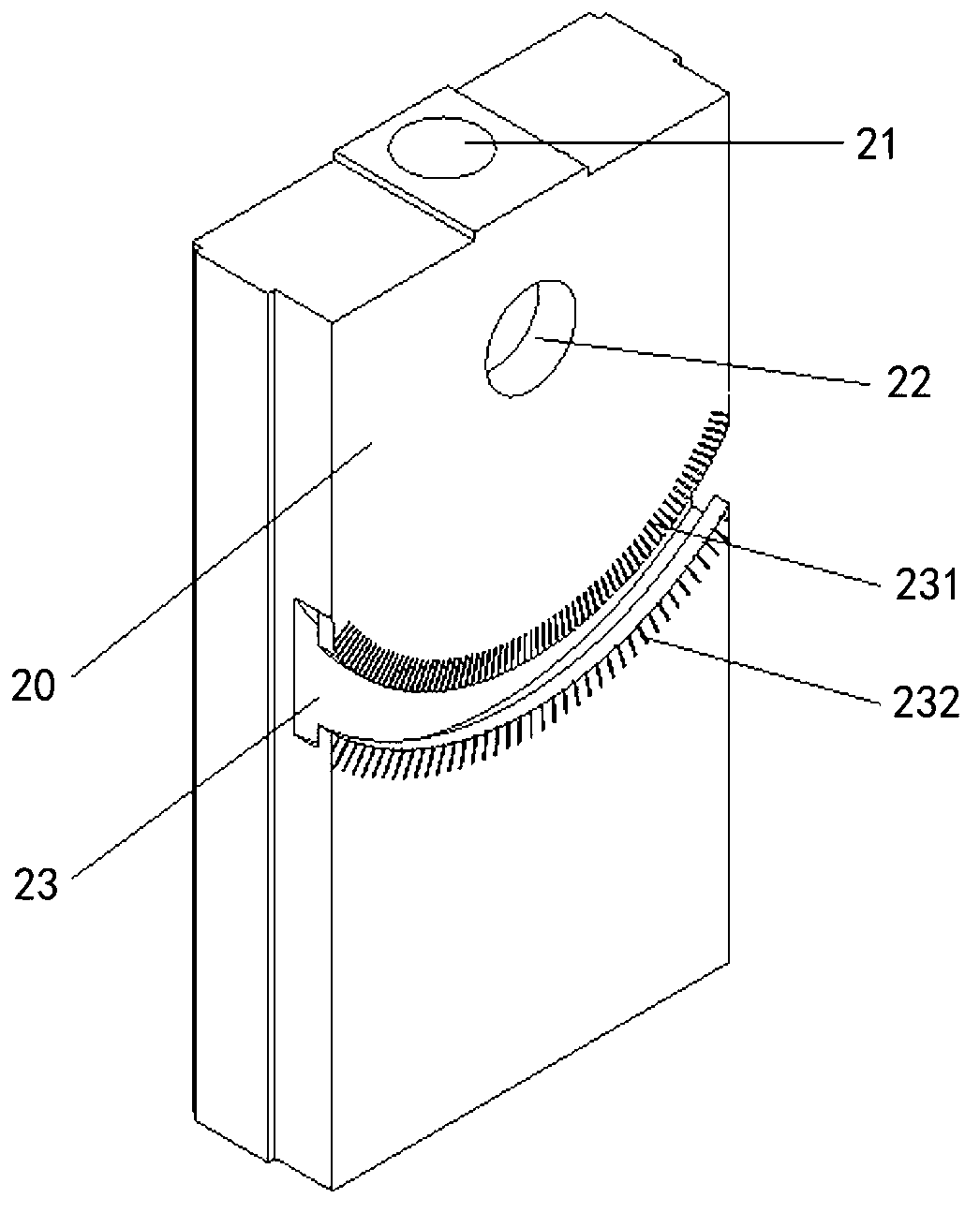

[0020] Such as figure 1 As shown, a clamp provided by the embodiment of the present invention includes a clamp base 10, a slider 20, a vertical adjustment assembly, a swing 40 and a clamping assembly. The vertical adjustment assembly is supported on the clamp base 10 in the vertical direction and is fixedly connected with the slide block 20 to adjust the relative position of the slide block 20 in the vertical direction with the clamp base 10; One end is rotatably connected to the slider 20, and the other end is installed with a clamping assembly.

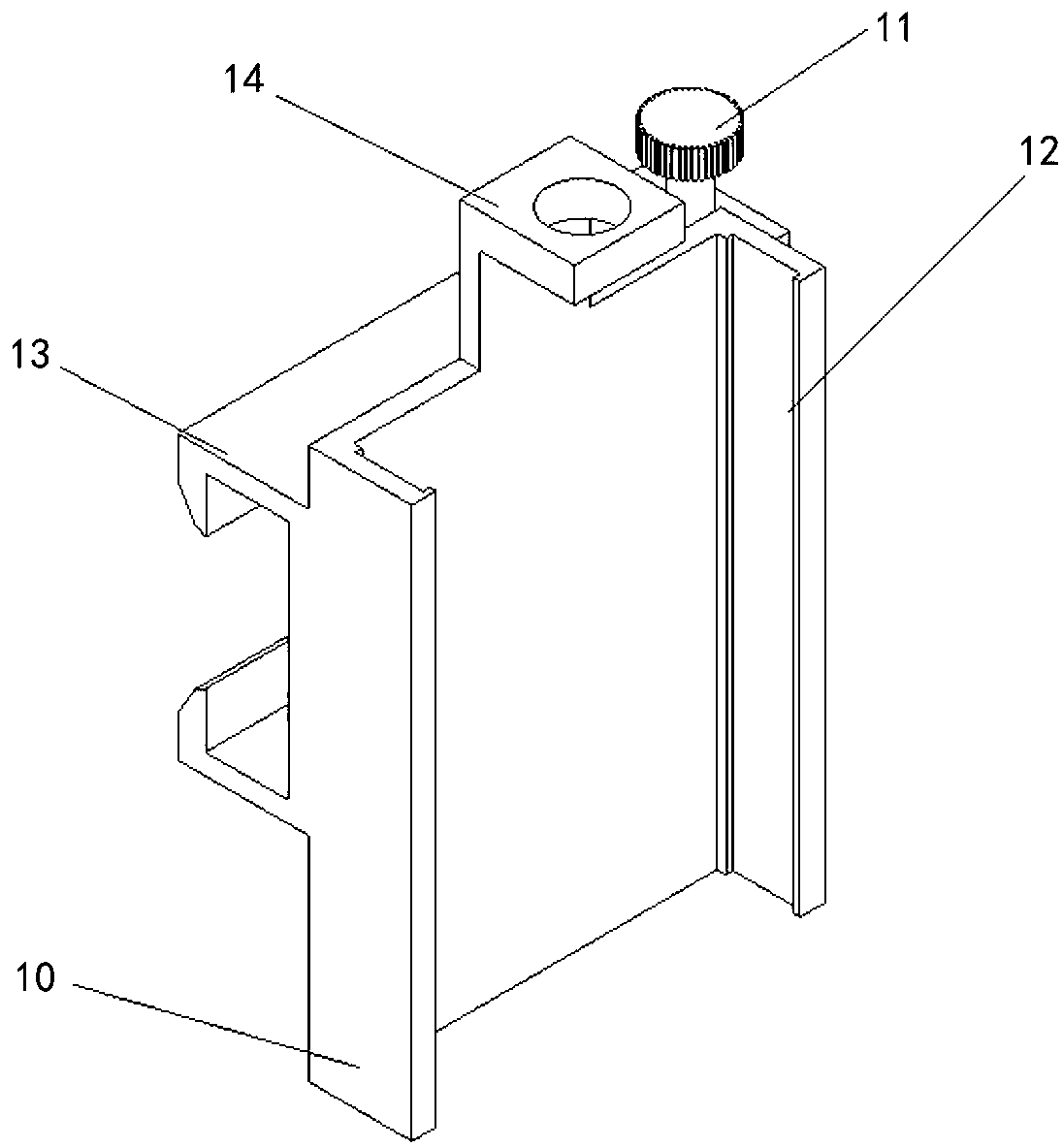

[0021] Specifically, combined with figure 2 As shown, the front side of the fixture base 10 has a vertical guide rail 12, and the slider 20 is installed in the guide rail 12 on the front side of the clamp base 10, and can be guided by the guide rail 12 along the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com