Ultrafiltration membrane bundle and processing method thereof

A processing method and ultrafiltration membrane technology, applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve the problems of many hours of work, not suitable for large-scale production, low labor efficiency, etc., and achieve low cost and continuous guarantee Sexuality and stability, the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

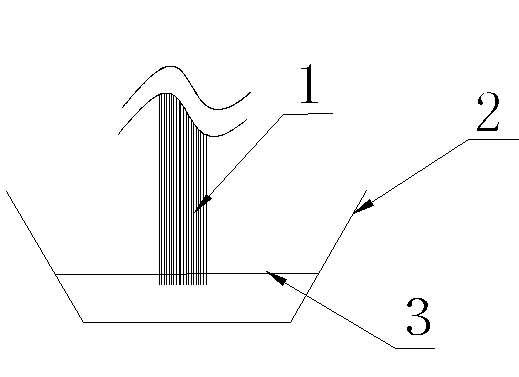

[0039] Such as figure 1 As shown, a bundle of 350 hollow fiber membranes with a length of 1.7m, an outer diameter of 1.1mm, and an inner diameter of 0.55mm forms an ultrafiltration membrane bundle 1, and the upper end serves as the packaging end. Fix the lower end with a rubber band, and cut it at a distance of 1 cm from the bottom to form a free end.

[0040] Pour the glue 3 into the package cup 2, lift the package end of the ultrafiltration membrane bundle 1 with a rope, insert the free end into the glue 0.5 cm, keep it constant and wait for the glue to solidify. The choice of glue 3 is different, and the solidification time is also different. 3 product description control time. After the glue 3 is solidified, it can be found that the outer wall of the ultrafiltration membrane bundle 1 is about 1 cm, and the inner wall is about 4-5 cm. We cut the ultrafiltration membrane bundle 1 with a blade at 1 cm from the lower end, and the membrane filaments will disperse naturally. ,...

Embodiment 2

[0044] A plastic outer tube with an outer diameter of 225mm, an inner diameter of 215mm, and a length of 1.5m is used, and the length is 1.7m. 350 hollow fiber membranes with an outer diameter of 1.1 mm and an inner diameter of 0.55 mm form an ultrafiltration membrane bundle 1, and one end of the ultrafiltration membrane bundle 1 is sealed manually. The plugged ultrafiltration membrane bundle 1 selects an appropriate number and puts it into a plastic outer tube, and uses a static packaging process for packaging. After the packaging is completed, cut the head, and then perform normal leak detection and flux measurement. The pressure is 0-0.15Mpa, and the test The result is normal. One end of the membrane filament is blocked by capillary phenomenon without leakage. The simulated operation is used for backwashing after one week of operation. The test result: the flux of the membrane filament is less damaged, and there is basically no sludge pollution in the tube. But the efficien...

Embodiment 3

[0046] Such as figure 1 As shown, a bundle of 1,000 hollow fiber membranes with a length of 1.7m, an outer diameter of 1.1mm, and an inner diameter of 0.55mm forms an ultrafiltration membrane bundle 1, and the upper end is cut neatly as the packaging end, and the packaging is fixed with glue.

[0047] Tighten the lower end with a rope and cut it 1 cm away from the bottom to form a free end. Seal the free end with the material of the coating head, the depth of the coating head is 0.5cm, and then pre-package with low adhesive strength silica gel, the pre-package height is 3cm, after the silica gel is solidified, cut off the end 1cm to expose the hollow The inner pores of the ultrafiltration membrane.

[0048] Pour the glue 3 into the package cup 2, lift the package end of the ultrafiltration membrane bundle 1 with a rope, insert the free end into the glue 3 by 0.5 cm, keep it constant and wait for the glue to solidify. After the glue 3 solidifies, the ultrafiltration membrane b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com