Electric vehicle charger based on single-cycle control strategy

A single-cycle control, electric vehicle technology, applied in electric vehicles, battery circuit devices, current collectors, etc., can solve the problems of complex system, high production cost, unstable system operation, etc., achieve high power factor, low cost, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

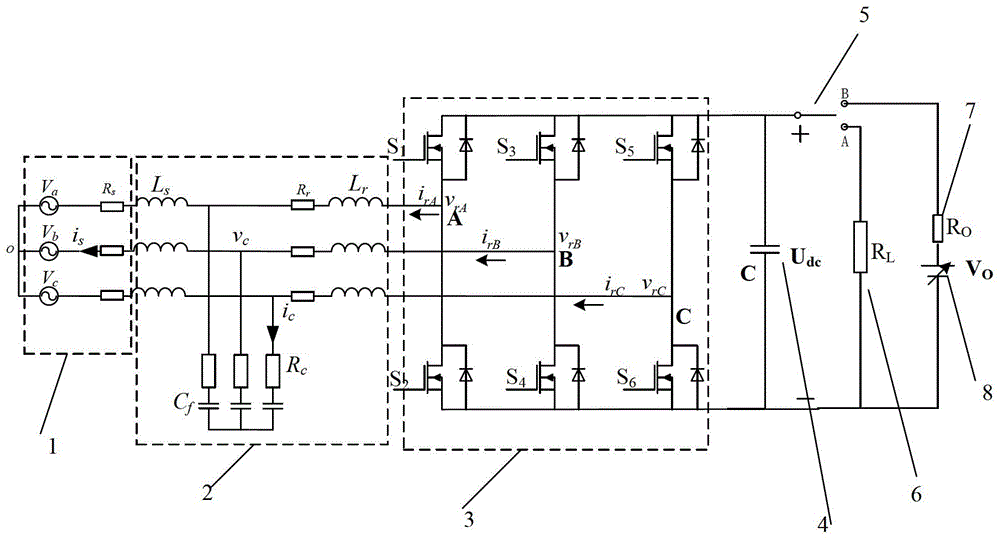

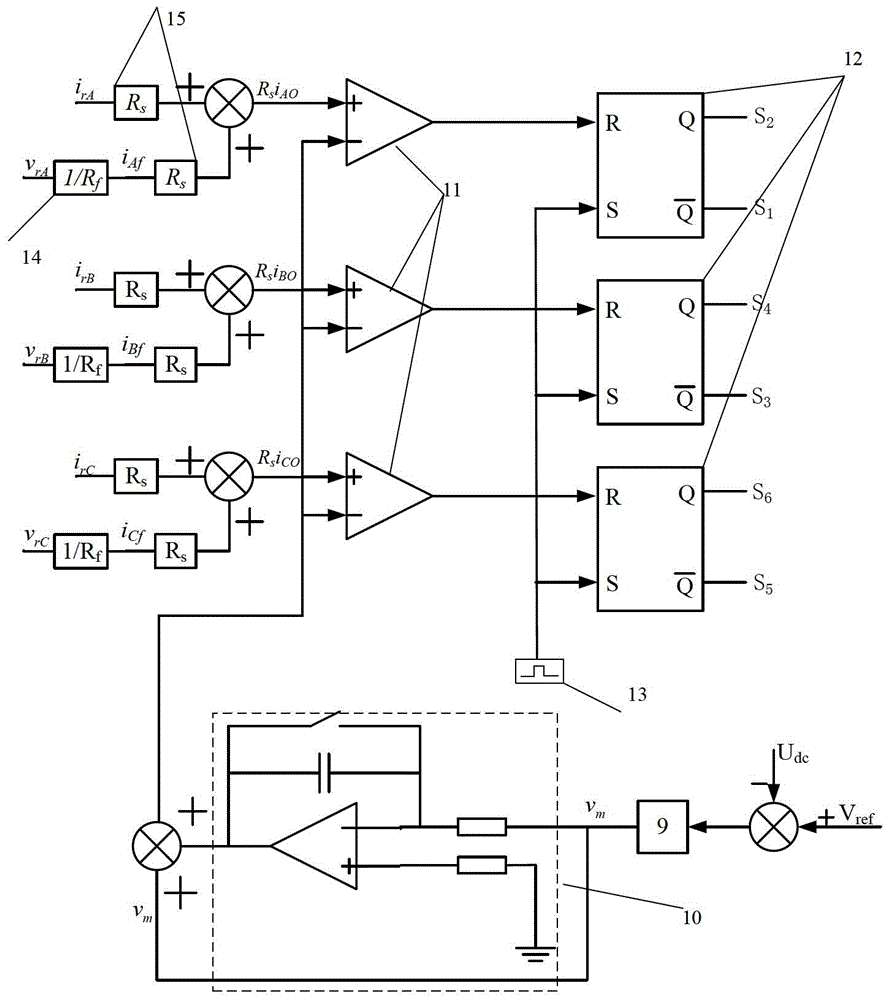

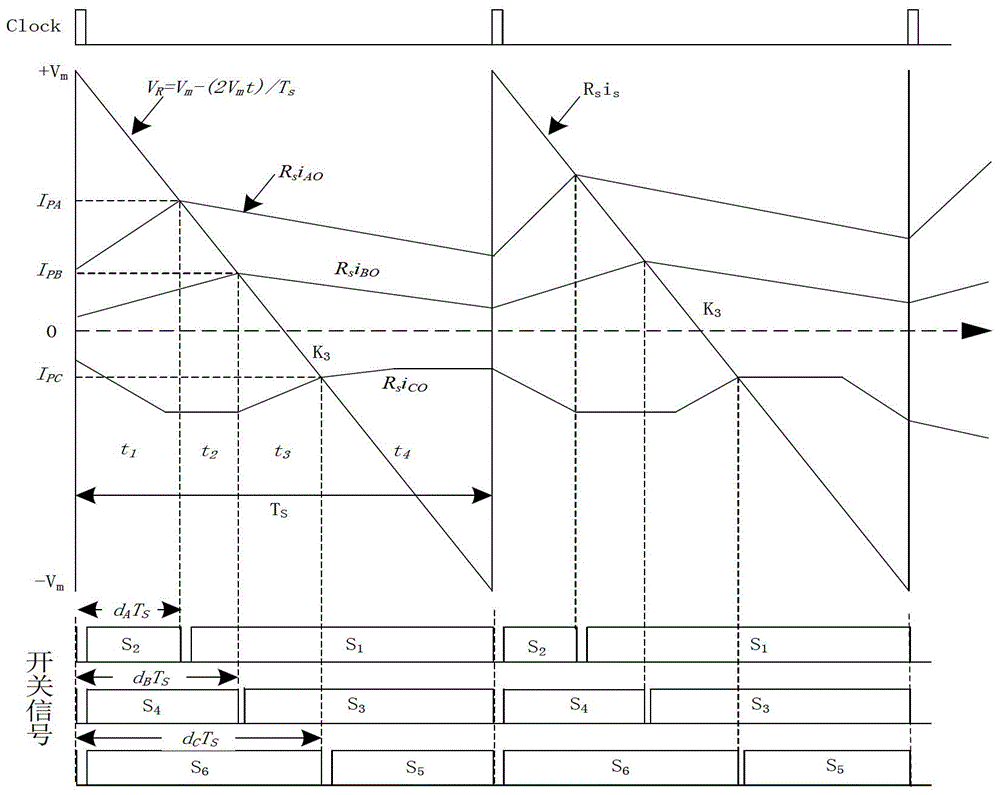

[0027] Such as figure 1 As shown, an electric vehicle charger based on a single-cycle control strategy includes a three-phase power supply 1, and the three-phase power supply 1 is connected to the LCL filter 2, and the LCL filter 2 is connected to the input terminal of the main circuit of the three-phase PWM power converter , the DC output terminal of the three-phase PWM power converter is connected in parallel with the support capacitor 4; at the same time, the first load 6 and the discharge circuit are connected in parallel with the DC output terminal of the three-phase PWM power converter through the selection switch 5; the control system of the three-phase PWM power converter Collect the current signal i of the LCL filter 2 inductor rn , the voltage signal v of the connection point between the LCL filter 2 and the input end of the main circuit of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com