Magnetically-controlled reactor control system

A magnetron reactor and control system technology, applied in the field of control systems, can solve problems such as phase error affecting control performance, unstable operation, system oscillation, etc., and achieve improved accuracy and stability, low cost, and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

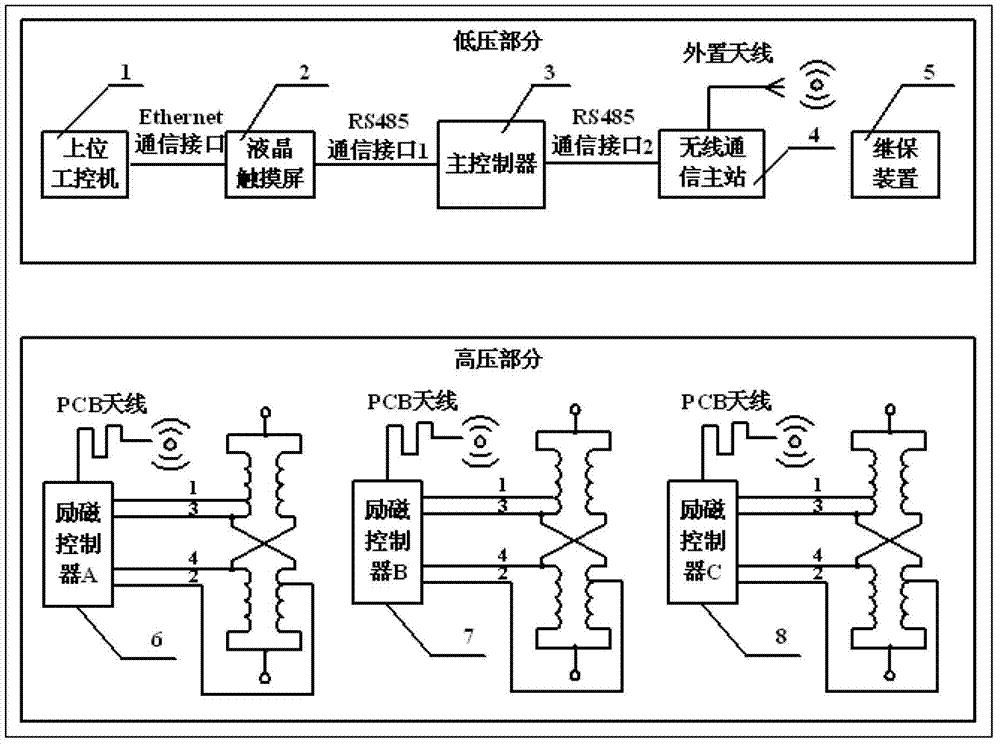

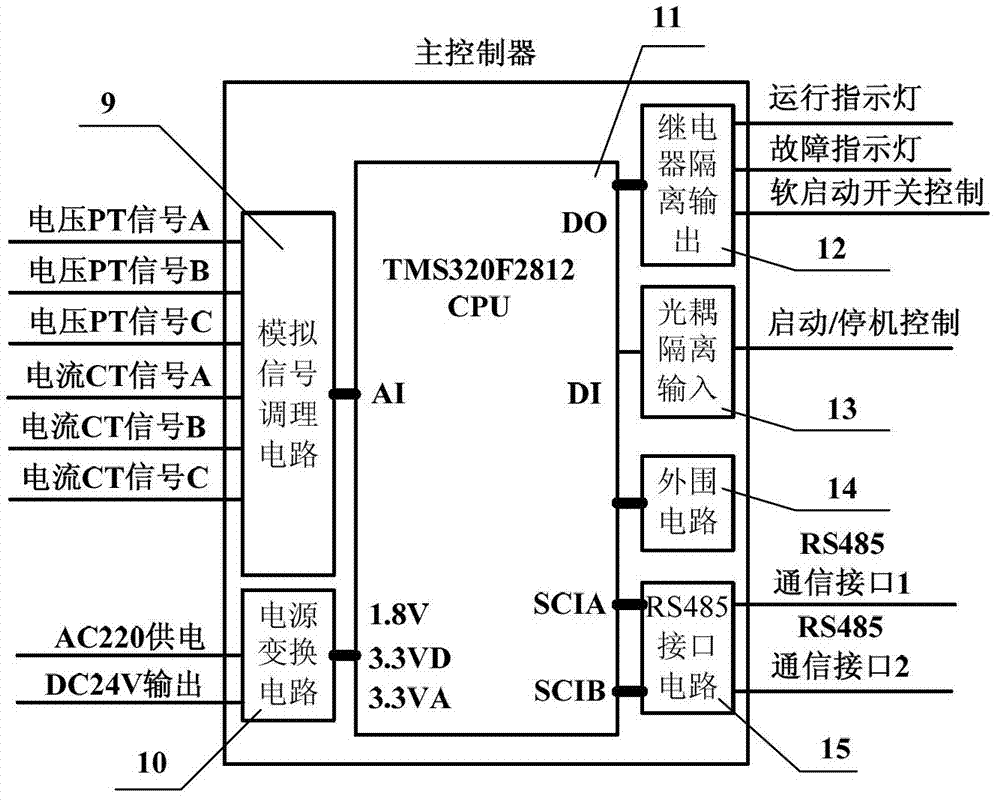

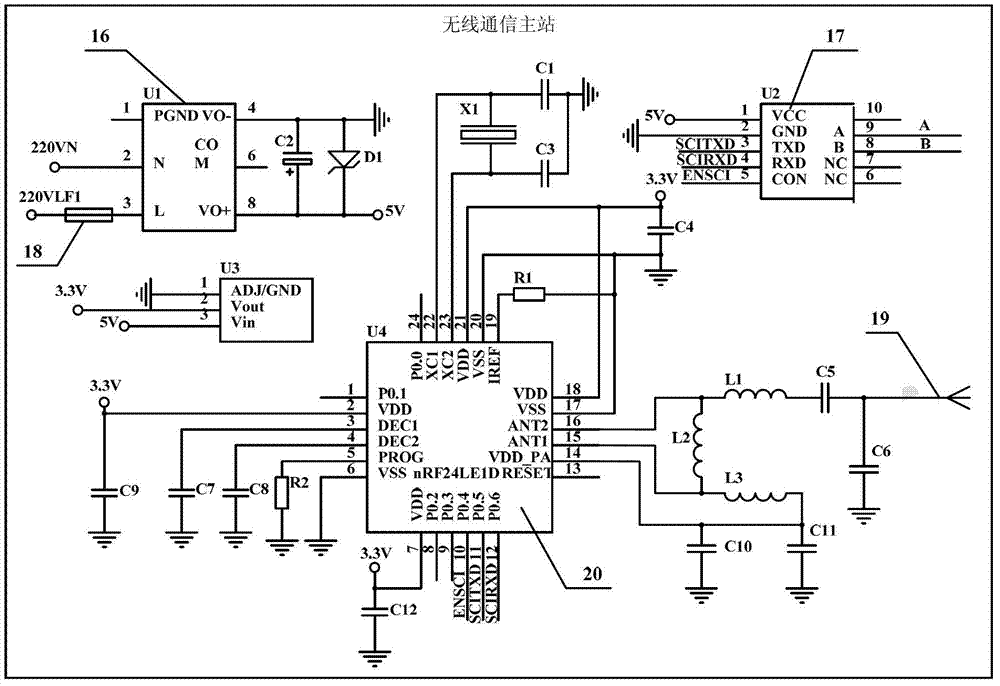

[0022] Such as figure 1 As shown, the present invention includes a high-voltage part and a low-voltage part, wherein the low-voltage part: detects voltage and current signals, completes the control function according to the control target, and sends the trigger angle data to the high-voltage part in a wireless communication mode; specifically includes the upper industrial computer connected in sequence 1. LCD touch screen 2. Main controller 3. Wireless communication master station 4. Relay protection device 5; High-voltage voltage part: Receive the trigger angle command from the low-voltage part through wireless communication, and upload the fault information and control winding voltage to the low-voltage part The main controller 3 specifically includes three excitation control components, and the three excitation control components respectively include an excitation controller A 6 , an excitation controller B 7 , and an excitation controller C 8 . The industrial computer 1 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com