A kind of LED heat dissipation substrate and its manufacturing method

A technology of a heat dissipation substrate and a manufacturing method, which is applied to electrical components, electric solid devices, circuits, etc., can solve the problems of reducing heat dissipation effect and poor heat dissipation performance, and achieves the effect of improving heat dissipation efficiency, avoiding heat dissipation bottlenecks, and high thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

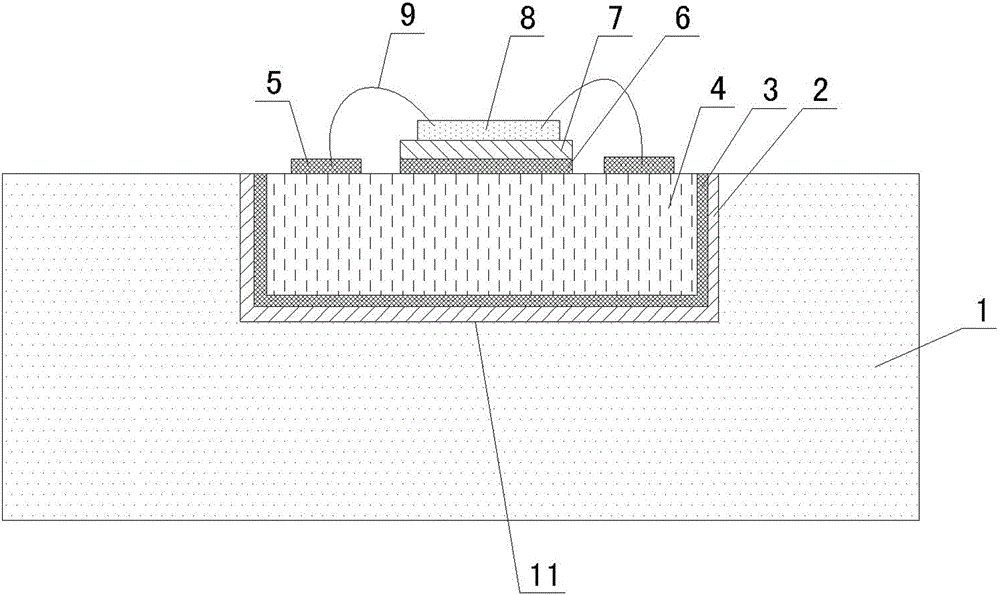

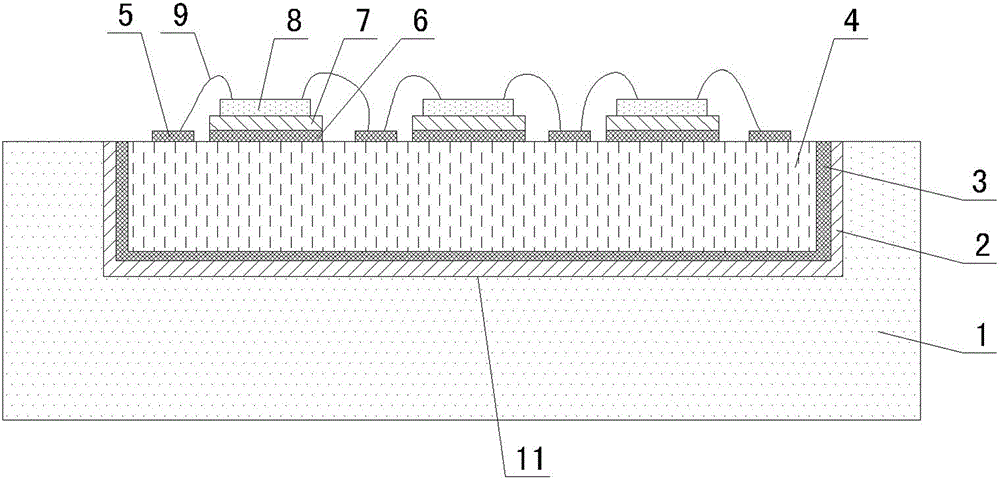

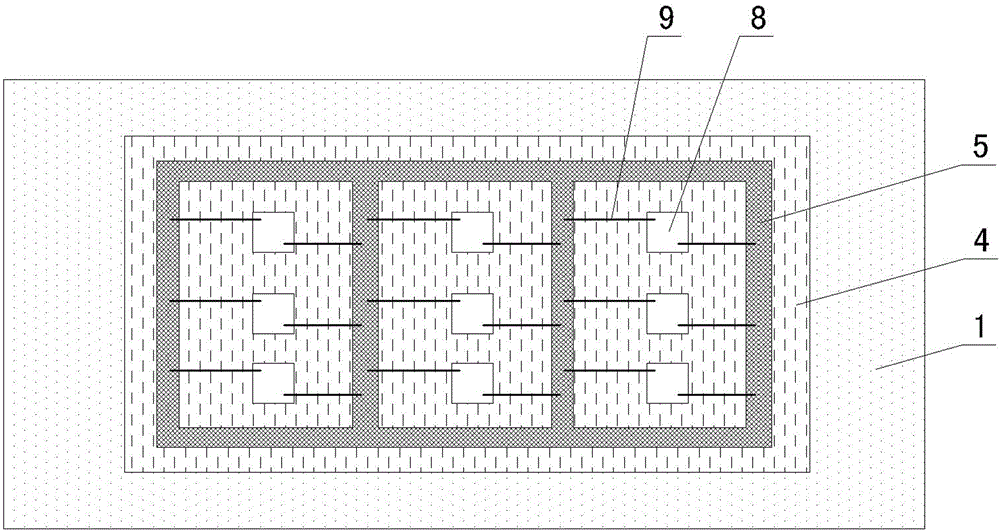

[0025] Such as Figure 1-Figure 3 As shown, the LED heat dissipation substrate of the present invention includes a substrate main body 1 made of a diamond-copper alloy material, and a groove 11 is opened on the substrate main body 1. The integrated diamond sheet 4 is connected by welding, and the upper surface of the diamond sheet 4 is provided with an electrode wire area 5 and a chip connection layer 6 for connecting the LED chip 8, and the chip connection layer 6 and the LED chip 8 are soldered. connected as one. Such as figure 1 As shown, only one LED chip 8 can be provided; as figure 2 and image 3 As shown, multiple LED chips 8 can be provided, and the arrangement and connection mode of each LED chip 8 can be adjusted according to actual needs;

[0026] The manufacturing method of the LED heat dissipation substrate of the present invention comprises the following steps:

[0027] Firstly, a groove 11 is opened on the substrate main body 1 made of diamond-copper alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap