Layered independent multipoint temperature control device applicable to machine tool temperature field differential control

A differentiated control, layered independent technology, applied in the direction of temperature control, computer control, general control system, etc., can solve the problems of single temperature of circulating fluid and inability to realize multi-point differential control of machine tool temperature field, so as to meet the requirements of different the effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

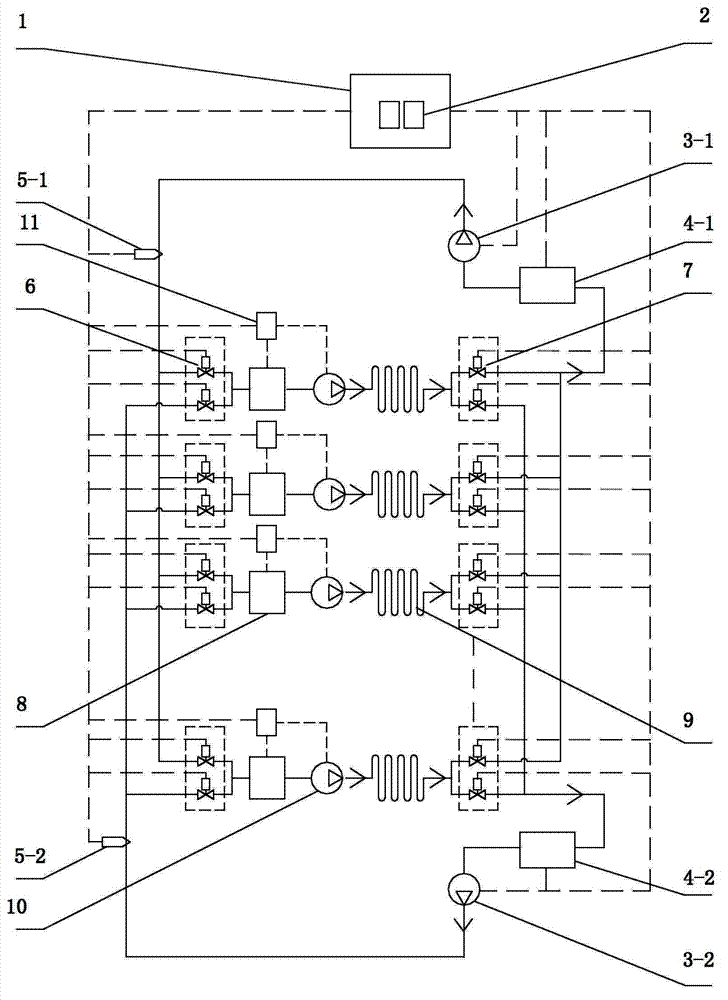

[0016] see figure 1 , a layered independent multi-point temperature control device suitable for differential control of the temperature field of a machine tool, including two sets of cooling circulation main circuits, multiple sets of cooling circulation branch circuits respectively connected to each group of cooling circulation main circuits, and a control system 1, The two groups of cooling circulation main circuits output different temperature coolants, and each group of cooling circulation main circuits includes a cooling circulation machine and a circulation pump, and the cooling circulation machine is equipped with a cooling liquid output temperature detection device and a liquid level detection devices such as figure 1 As shown, one o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com