Sunk duct piece test platform

A test platform and segment technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of limited research scope, single research purpose, restricted test research field and research space, etc., to save test space, The effect of easy detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The sunken segment test platform of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention cannot be limited by this.

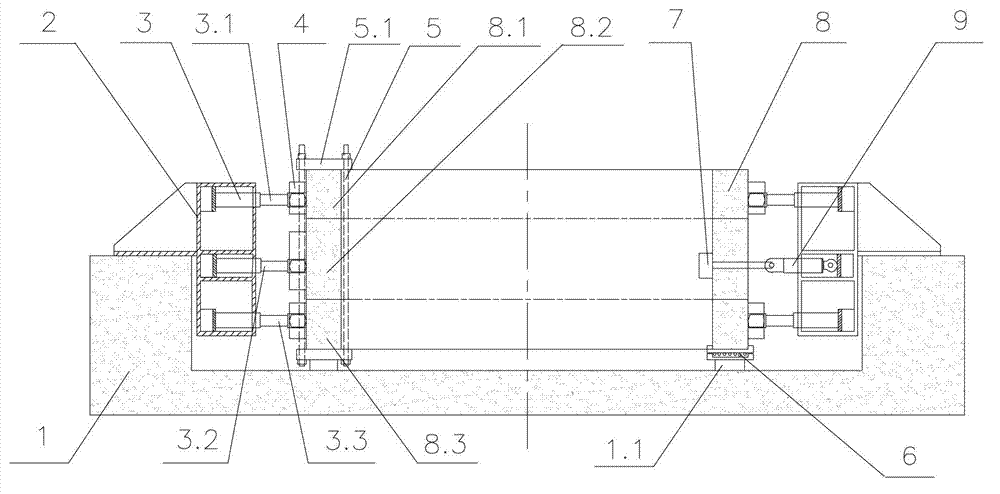

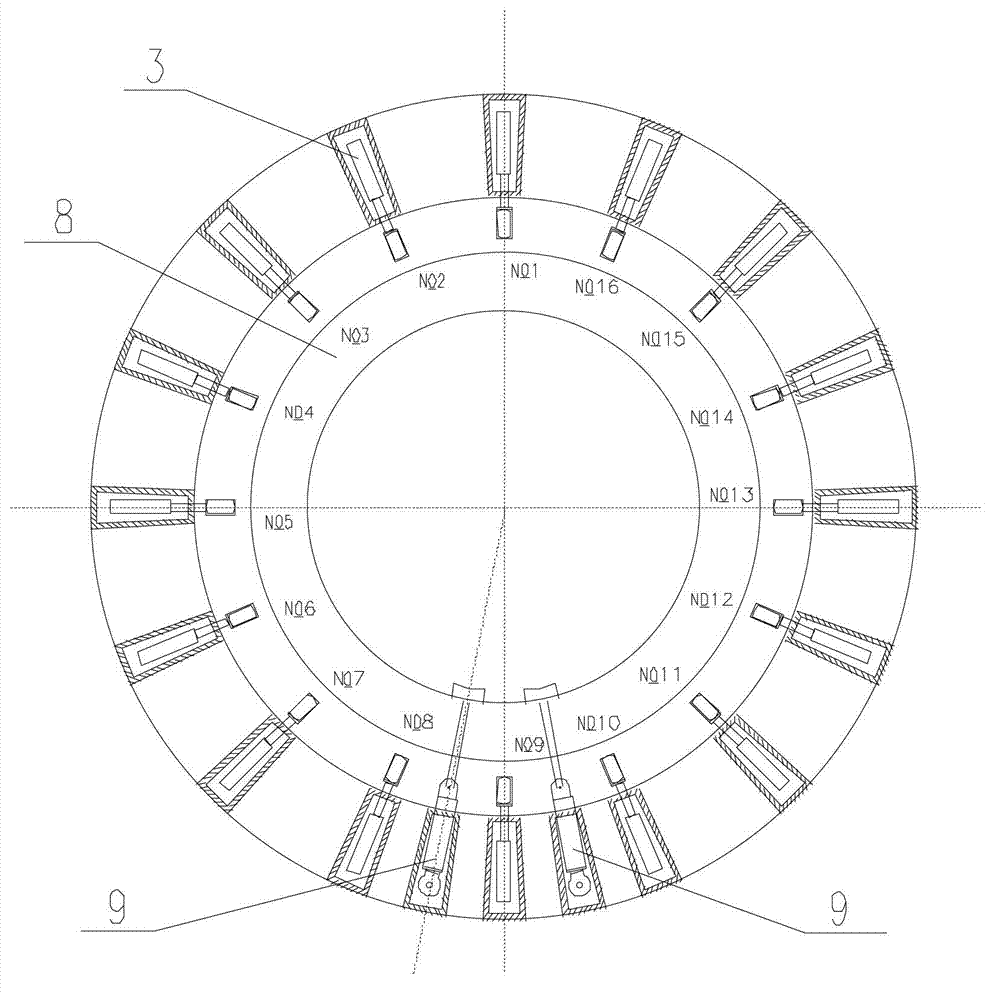

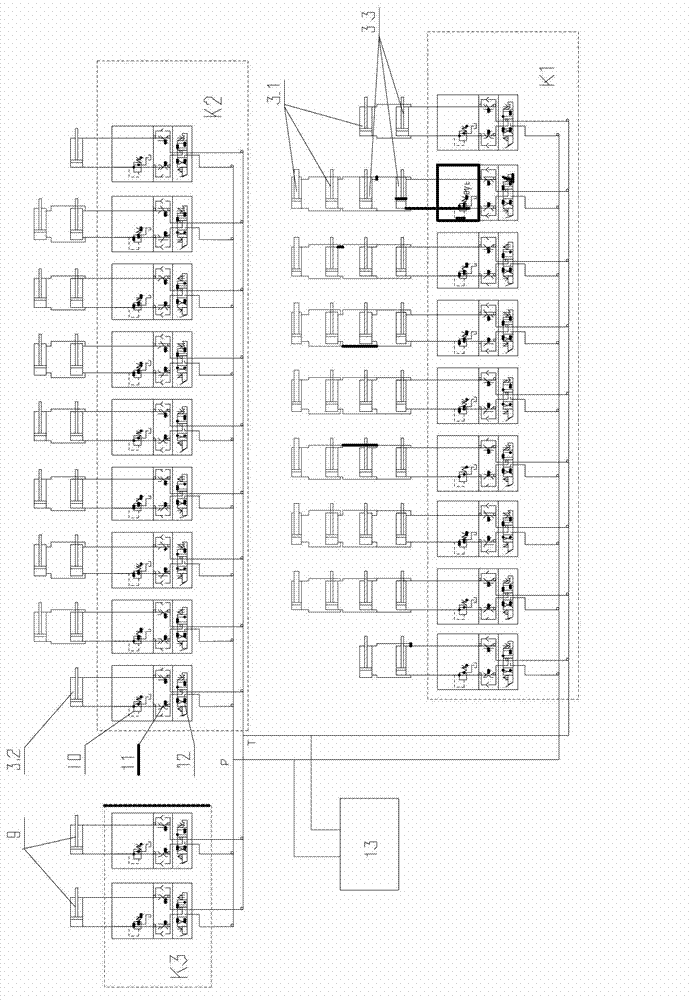

[0020] see figure 1 with figure 2 , the illustrated sunken segment test platform includes a soil pit 1, a segment 8, a loading system, a control system, a monitoring system (not shown in the figure) and a data acquisition system (not shown in the figure). The sunken segment test platform has a clearance diameter of 8.5m, a clearance depth of 1.5m, and a design maximum uniform loading capacity of 0.5MPa.

[0021] The pit 1 is an open cylindrical pit dug under the ground; the pit bottom of the pit 1 is provided with a bottom plate 1.1 supporting the segment 8, and the lower end surface of the segment 8 is in contact with the segment 8. Balls 6 are arranged between the bottom plates 1.1 to form rolling bearing conditions wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com