System and method for determining nonlinear membrane stress

A film stress, nonlinear technology, applied in the direction of measuring force, measuring fluid pressure, measuring device, etc., can solve the problems of difficult measurement, low analysis efficiency, and no consideration of the coordination conditions between the matrix and the film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

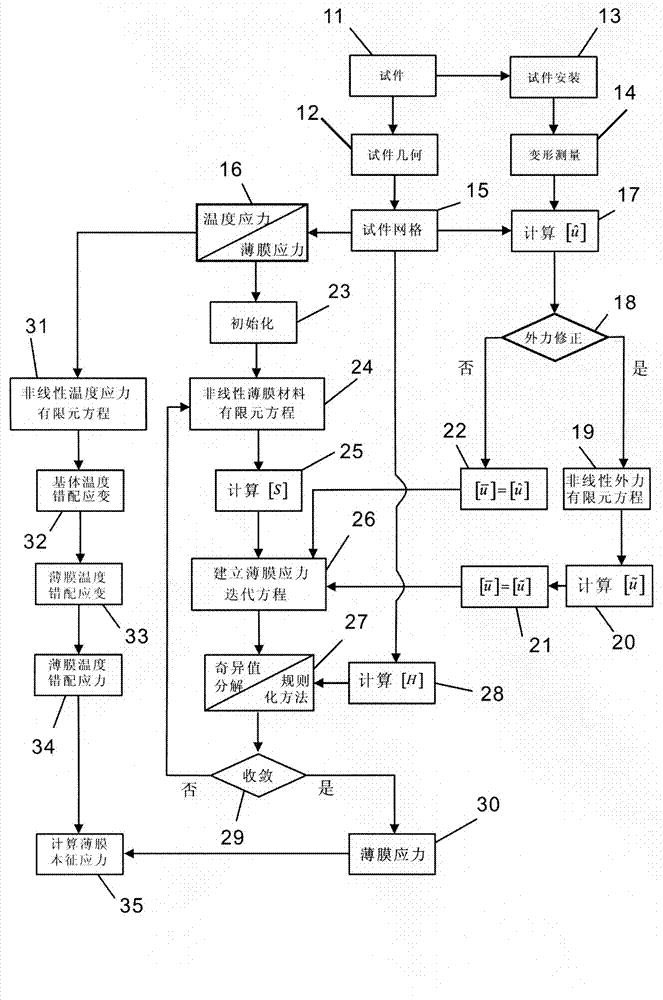

[0118] The implementation of the present invention will be described below through three examples.

[0119] Membrane stress is determined by measuring the in-plane deformation in the thin film material: Consider a planar rectangular base material with dimensions , Young's modulus is , Poisson's ratio is , the density is , generating a thick uniform film. The deflection of the substrate due to the deformation of the thin film material is close to the thickness of the substrate, so it belongs to the nonlinear deformation problem. The steps of using the method of the present invention to predict the nonlinear film stress through the measured in-plane deformation displacement in the matrix are as follows:

[0120] (1) The user installs the substrate without film and the film material with film on the measuring platform respectively;

[0121] (2) Use shape measuring equipment to measure the shape data of the substrate without the film and the shape data of the substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com