Glass heat pipe with solid-liquid working medium package and manufacturing method thereof

A technology of glass heat pipes and manufacturing methods, which is applied in heating devices, solar thermal devices, solar thermal power generation, etc., and can solve the problems of damage to perfusion equipment, high frequency of equipment maintenance, and impact on the performance and reliability of all-glass heat pipe vacuum solar collector tubes, etc. problem, to achieve the effect of improving heat collection and heat transfer performance and realizing large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the shape, structure and characteristics of the present invention, preferred embodiments will be listed below and described in detail with reference to the accompanying drawings.

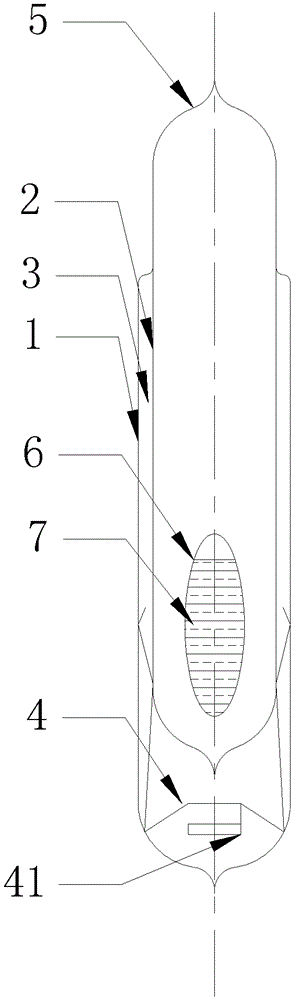

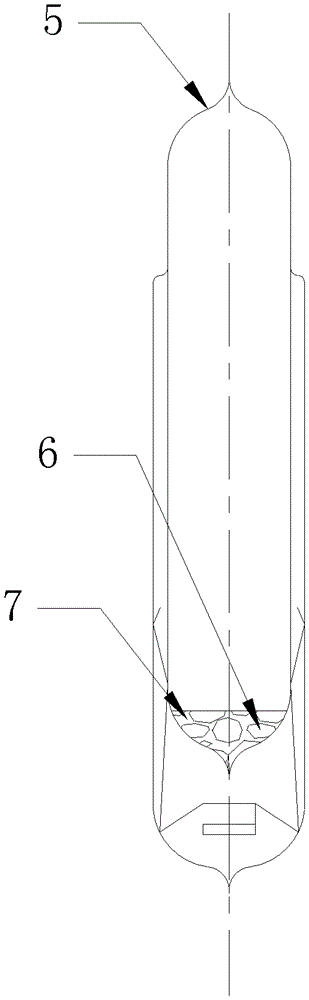

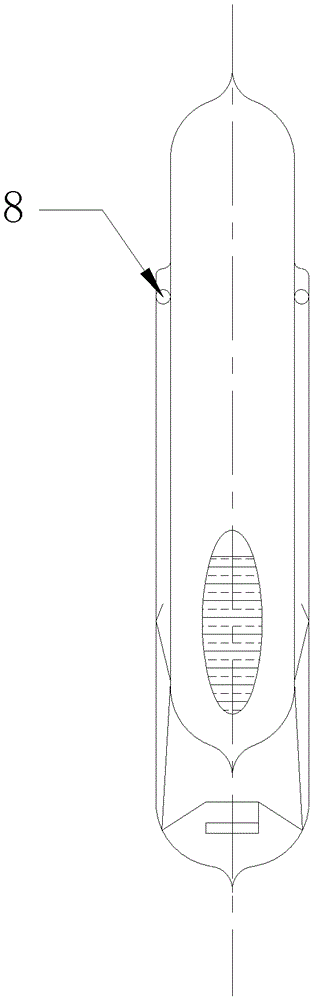

[0022] Figure 1-4 is a structural schematic diagram of the glass heat pipe of the present invention, such as the present invention figure 1 Shown is a schematic diagram of the structure of the glass heat pipe working fluid package in an inactive state. The all-glass heat pipe vacuum solar collector tube (referred to as the glass heat pipe) includes a cover glass tube 1, and a heat collecting end sleeve of an inner tube 2 with a selective absorption coating. It is arranged in the cover glass tube 1, and the condensation end 5 of the heat pipe protrudes outside the cover glass tube 1.

[0023] There is a vacuum interlayer 3 between the inner tube 2 and the cover glass tube 1, and a clamp 4 with a getter 41 is arranged between the cover glass tube 1 and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com