Sand-gravel material bag sealing machine

A sand and gravel, bag sealing technology, applied in packaging sealing/fastening, external support, transportation packaging, etc., can solve the problems of poor sealing quality, poor bagging efficiency, easy leakage, etc., and achieve good sealing quality, high efficiency, The effect of not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present application will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

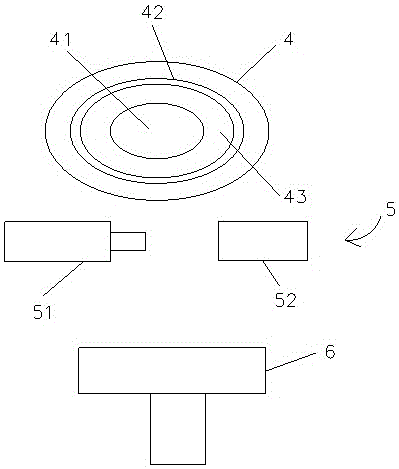

[0015] like figure 1 Shown, a kind of gravel material bag sealing machine, wherein has support frame 4, through hole 41, electromagnet 42, metal briquetting 43, binding machine 5, sealing machine head 51, nail plate 52 and jacking platform 6 etc. main technical characteristics.

[0016] A gravel material bag sealing machine, including a support frame, a sealing machine and a jacking platform; a through hole is arranged in the center of the support frame, an annular electromagnet is built in the edge of the through hole, and an annular metal briquetting block is placed above the through hole; When the electromagnet is energized, the metal briquetting block can be attracted to the electromagnet; the sealing machine is coaxially arranged directly below the support frame, and the sealing machine includes a sealing head and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com