Superheated steam and subcritical pressure steam generator

A steam generator and superheated steam technology, which is applied in steam generation, steam boilers, water-tube steam boilers, etc., can solve the problems of inability to meet the growing needs, the water content of produced fluids increases, and the production of heavy oil decreases. The effect of saving procurement costs, improving utilization, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

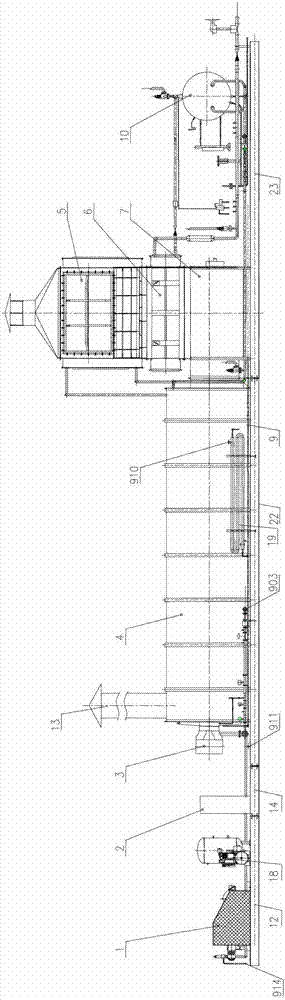

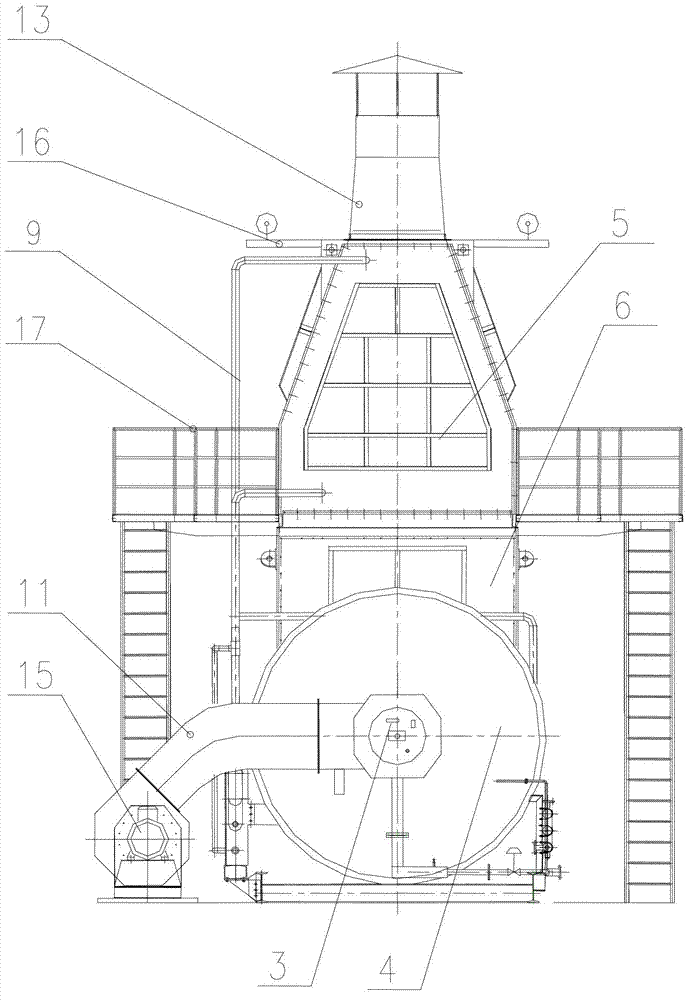

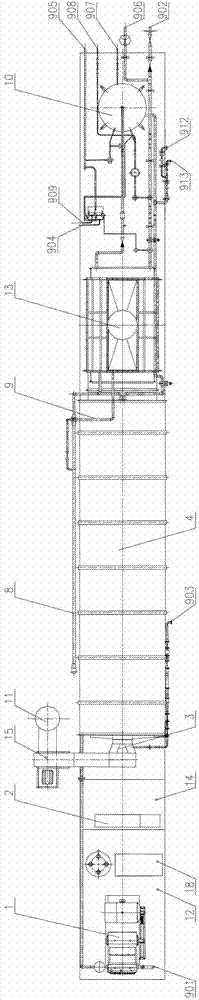

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

[0040] The reference numbers in the figure are as follows: feed water pump 1, control cabinet 2, burner 3, furnace 4, convection steel pipe economizer 5, superheater 6, connecting flue 7, water-water heat exchanger 8, pipeline 9, Steam-water separator 10, air duct 11, feed pump skid 12, chimney 13, control cabinet skid 14, blower 15, pulley 16, ladder platform 17, air compressor 18, oil heater 19, electric heater 20, mist Chemical separator 21, furnace skid seat 22, connecting flue and steam-water separator skid seat 23; furnace tube bundle 401, convection steel pipe economizer tube bundle 501, superheater tube bundle 601, feed water inlet 901, steam outlet 902, natural gas inlet 903 , Sampling cooling water inlet 904, cold water inlet 801, cold water outlet 802, hot water inlet 803, hot water outlet 804, separator external pipeline sewage outlet 905, vent 906, separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com