Connecting and sealing structure of valve body and gas cylinder

A sealing structure and gas cylinder technology, which are applied in the directions of engine sealing, gas/liquid distribution and storage, and container discharge methods, etc., can solve the problems that it is difficult to completely seal the gas cylinder and the valve body, and the sealing structure is not mentioned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

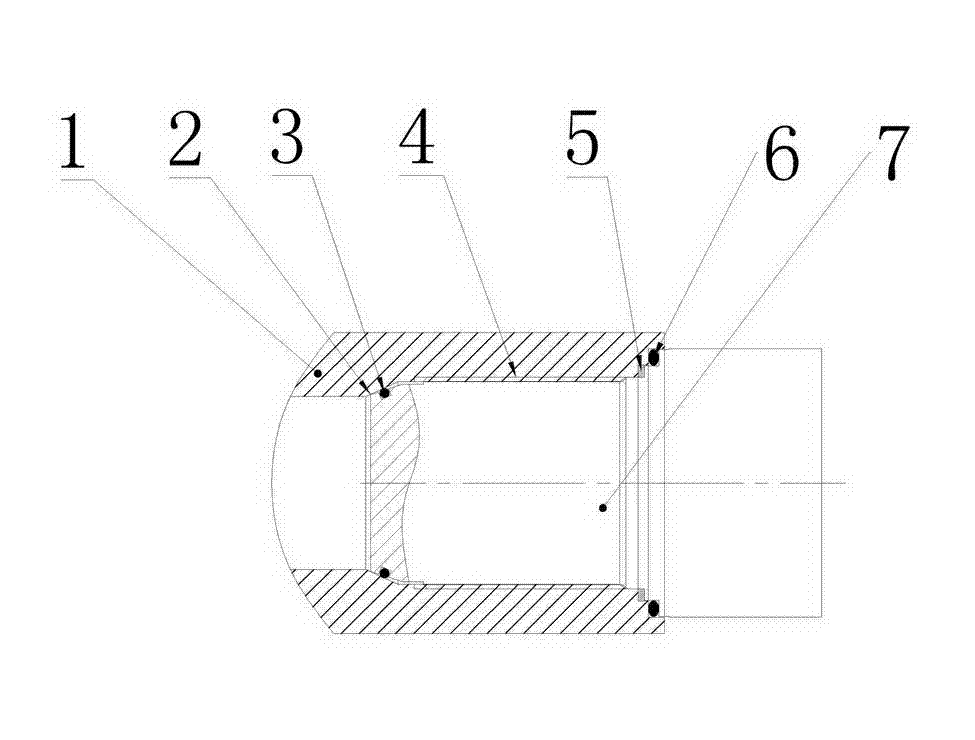

[0015] The connection sealing structure provided by the present invention includes: gas cylinder mouth 1, linear seal 2, O-ring I seal 3, thread structure 4, aluminum pad (or oxygen-free copper pad) seal 5, O-ring II seal 6 and valve body 7.

[0016] The specific embodiment of the present invention is: linear seal 2, O-ring I seal 3, thread structure 4, aluminum pad (or oxygen-free copper pad) seal 5, O-ring II seal 6 and valve body 7 are made as a whole, The linear seal 2 and the O-ring I seal 3 are on the conical surface, and the inner side of the gas cylinder mouth 1 is matched with the thread of the thread structure 4. The position corresponding to the linear seal 2 is also a conical surface structure, but the two conical surface structures The taper is different, the gas cylinder and the valve body are connected together through threaded connection, O-ring I seal 3 and O-ring II seal 6 are used as two soft seals, linear seal 2 and aluminum gasket (or oxygen-free copper ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com