A method for recovering in-situ regenerated foam oil in deep heavy oil reservoirs

A technology for heavy oil reservoirs and mining methods, applied in the field of heavy oil reservoir mining and deep heavy oil reservoir mining, can solve the problems of no economical and efficient mining methods, low cycle yield, poor economic benefits, etc., to achieve Avoid the effects of rapid degassing, high flow capacity, and high elastic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

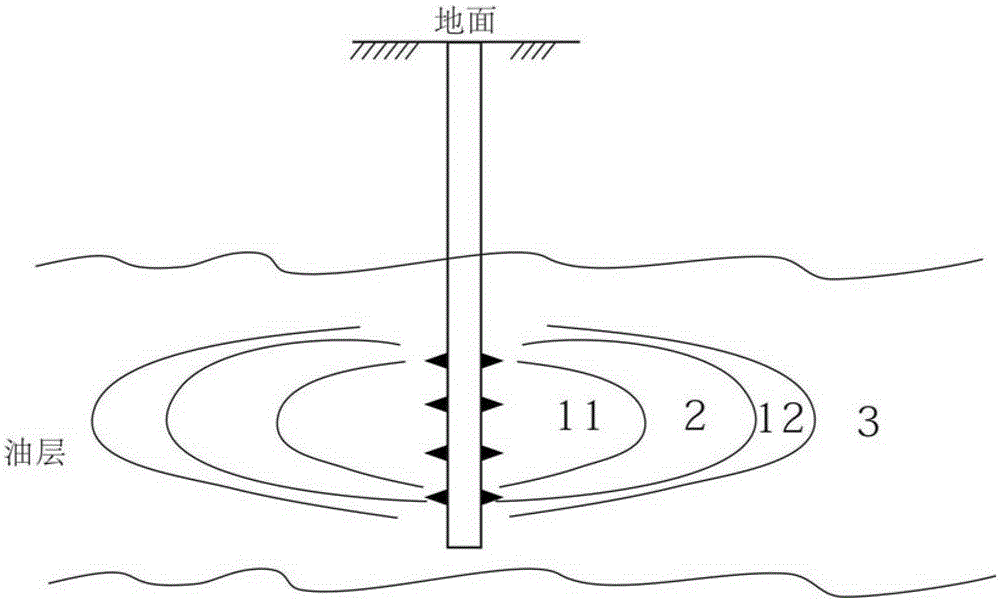

[0030] The general principle of the production method of the present invention is explained below by taking a deep heavy oil reservoir in Turpan-Hami as an example, but it should be noted that the present invention is by no means limited to the heavy oil reservoir in Turpan-Hami Oilfield. The depth of the reservoir is about 2000m, the viscosity of crude oil at the reservoir temperature is about 10000 centipoise, and the density is 0.97cm 3 / g, the original average formation pressure was 18.0MPa.

[0031] (1) Well layout parameters

[0032] Newly drilled wells adopt the vertical well determinant well pattern layout, the well spacing is 100m, and the row spacing is 100m;

[0033] (2) Select n-heptane as the light alkane solvent, the injection volume of the slug mixing system of solvent and natural gas is 200t / cycle, and the ratio of light alkane solvent to natural gas mass slug is 1:1, that is, n-heptane 100t, 100t of natural gas, the mass ratio of two light alkane solvent slu...

Embodiment 2

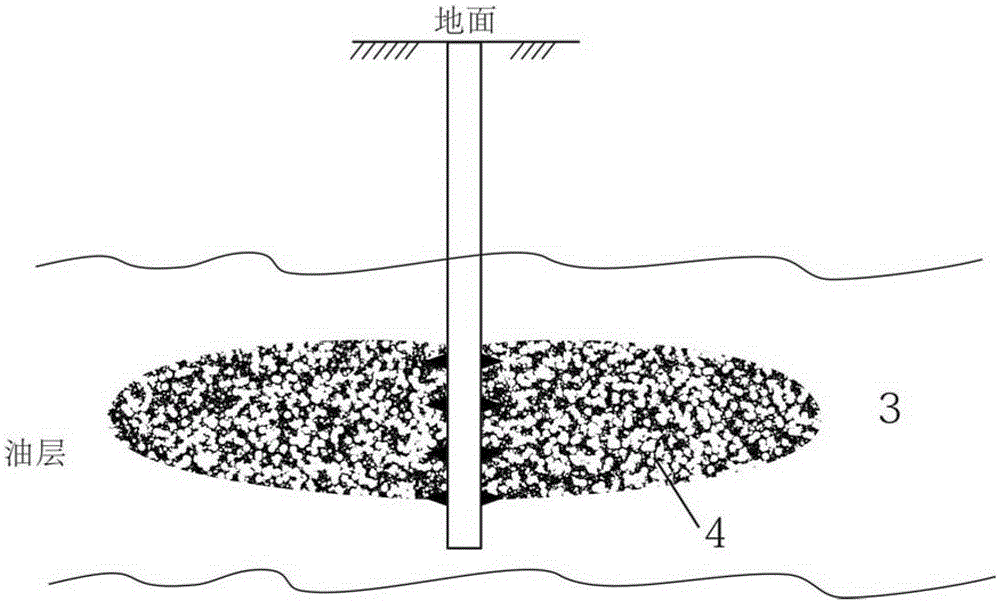

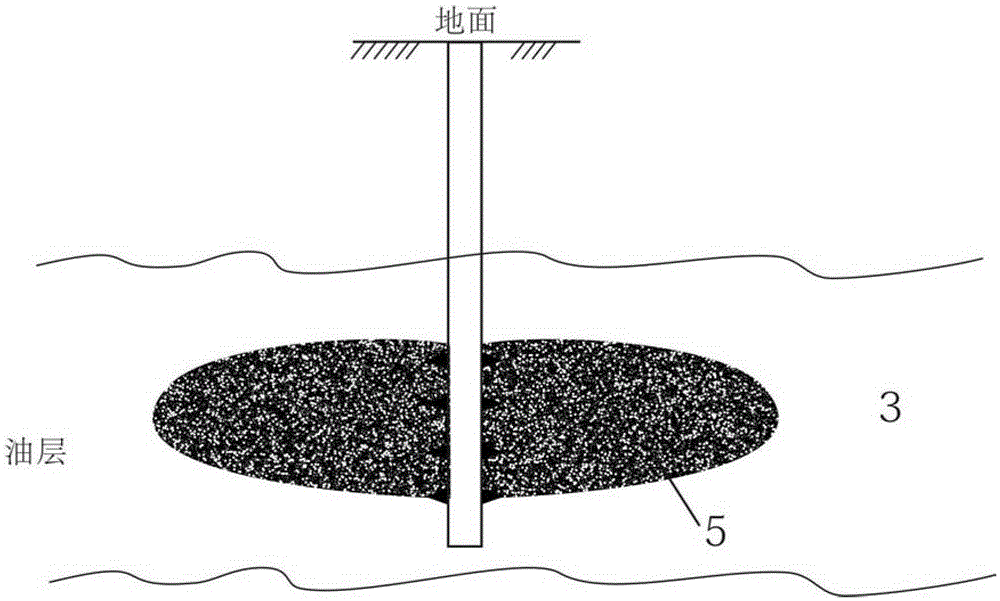

[0041] The general principle of the production method of the present invention is explained below by taking a deep heavy oil reservoir in Turpan-Hami as an example, but it should be noted that the present invention is by no means limited to the heavy oil reservoir in Turpan-Hami Oilfield. The depth of the reservoir is about 2500m, the viscosity of crude oil at the reservoir temperature is about 30000 centipoise, and the density is 0.98cm 3 / g, the original average formation pressure is 21.0MPa.

[0042] (1) Well layout parameters

[0043] For new drilling, the horizontal wells are arranged in rows and arrays, and the distance between the horizontal sections of adjacent horizontal wells is 200m;

[0044] (2) Select n-octane as the light alkane solvent, the injection volume of the slug mixing system of solvent and natural gas is 300t / cycle, and the ratio of light alkane solvent to natural gas mass slug is 1.2:1, that is, n-octane 163t, 136t of natural gas, the mass ratio of tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com