Method for integrally mounting hinge device of extra-large sector gate

An overall installation and super-large technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of large overall weight of support hinges, high installation accuracy requirements, and complicated installation positions, so as to improve installation quality and shorten construction period , the effect of reducing the risk of working at heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

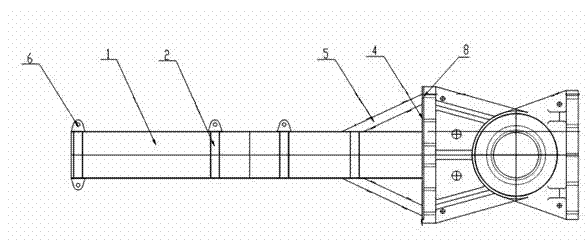

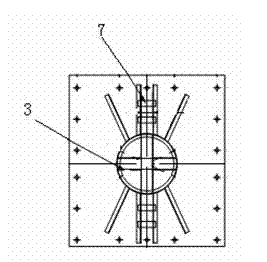

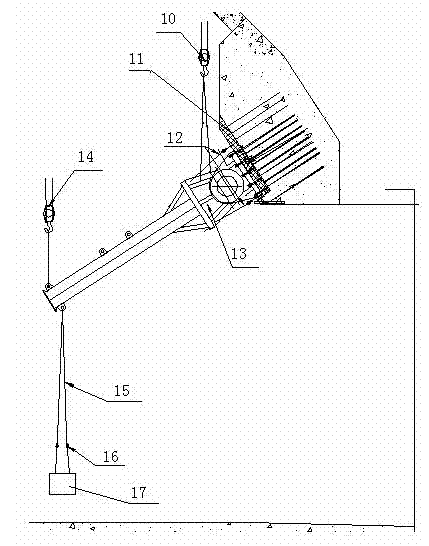

[0013] The overall installation and construction method of the ultra-large arc gate hinge device of the present invention is as follows:

[0014] According to the design drawings, the overall weight of the hinge device is about 93t, and the installation height is 18m. According to the actual measurement on site, the center of the hinge axis is 410mm away from the concrete above the hinge beam. The crane head protrudes 400mm. It can be calculated that the head of the 300t truck crane will not collide with the concrete of the hinge girder during the precise installation of the hinge. Therefore, a 300t truck crane and a 130t truck crane are used together, and two Φ60.5 steel wire ropes with a length of 12m are used for overall hoisting of the hinge.

[0015] First find a flat place, level the movable hinge and the fixed hinge of the curved gate hinge device, use a pressure steel pipe to weld the heating block to preheat the hinge, and then use a steel plate with the same materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com