2-ferrocenyl-arylquinoline and preparation method thereof

A ferrocene-based and aryl-quinoline technology, applied in the field of materials, achieves the effects of a wide range of substrates, mild reaction conditions, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

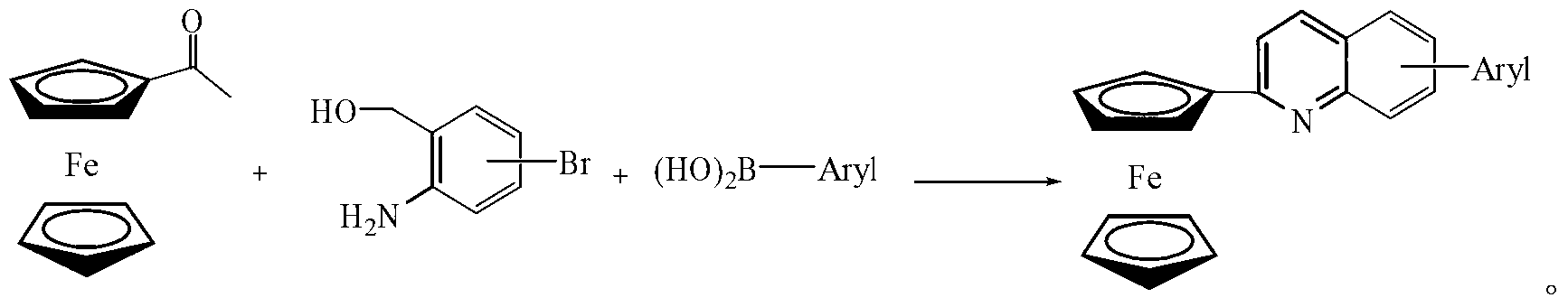

Method used

Image

Examples

Embodiment 1

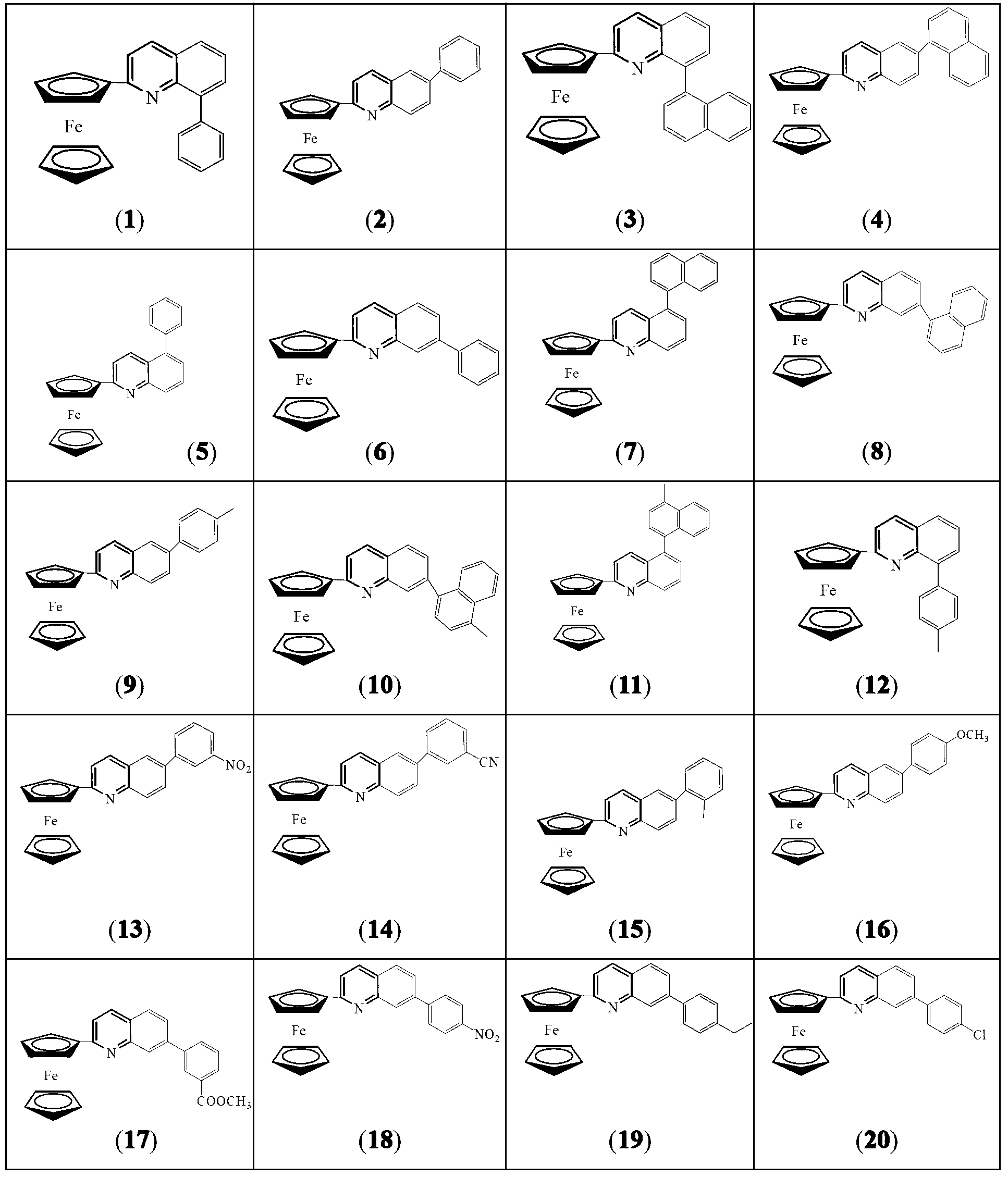

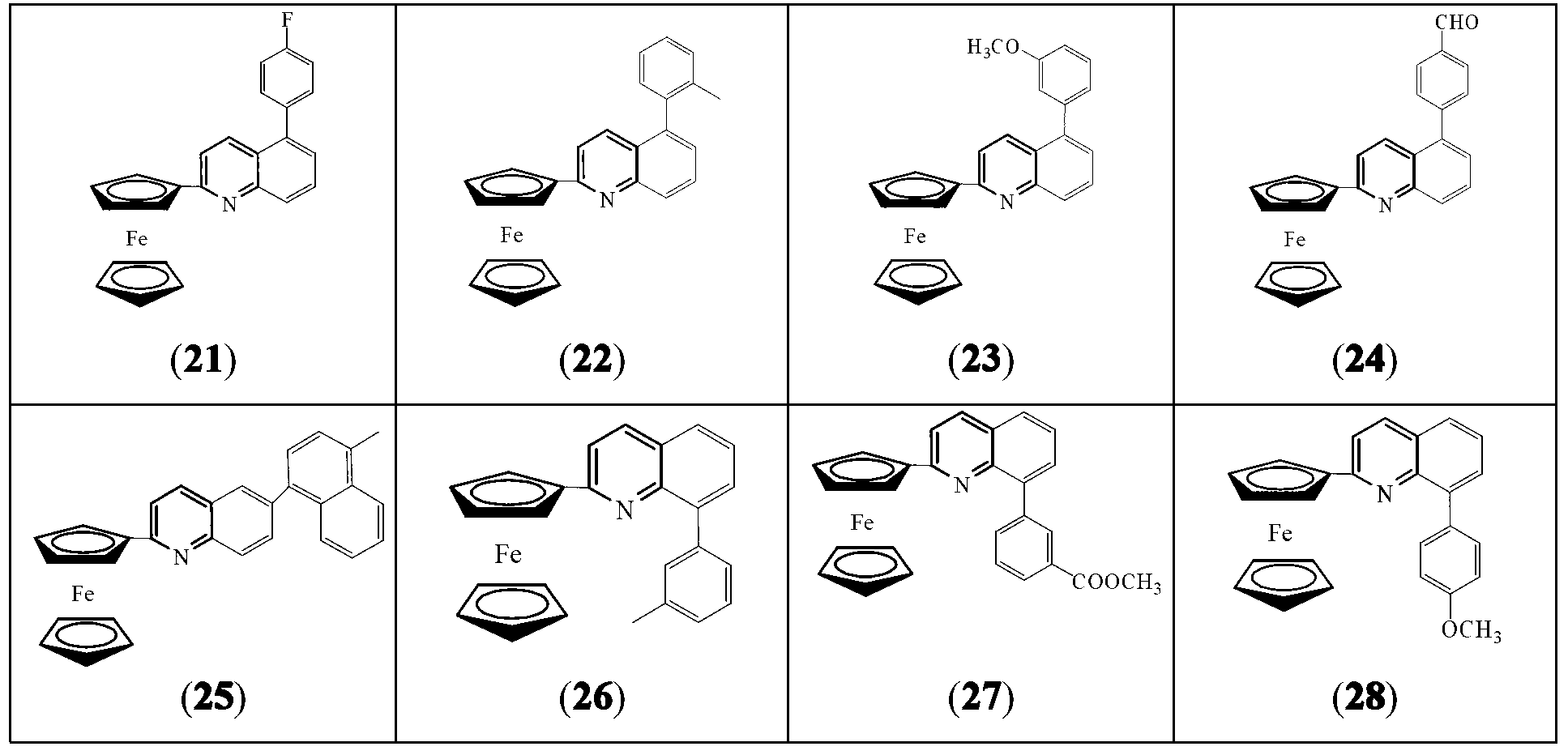

[0023] 2-ferrocenyl-arylquinoline, the general formula is:

[0024] The specific structure can be:

[0025]

[0026]

Embodiment 2

[0028] Compound (1) Preparation of 2-ferrocenyl-8-phenylquinoline: under the protection of high-purity nitrogen, add 1.0mmol acetylferrocene and 1.5mmol 6-bromo-o-hydroxymethyl to a 10ml Schlek reaction tube Aniline, 2.0mmol phenylboronic acid, 0.05mmol [Ir(cod)Cl] 2 , 0.05mmol palladium chloride, 0.15mmol triphenylphosphine, 3.0mmol sodium hydroxide and 5ml dioxane, replace the reaction tube with nitrogen for 3 times, then heat to 110°C with an oil bath under magnetic stirring, and reflux for 16 Hour.

[0029] The oil bath was removed, and the water bath was lowered to room temperature; 3ml of water was added to the reaction solution, extracted three times with 5ml of dichloromethane, the organic phases were combined and washed with anhydrous MgSO 4 Dry for 30 minutes, filter, and concentrate the filtrate with a rotary evaporator. The concentrated residue is separated by silica gel column chromatography using dichloromethane as a developing solvent to obtain pure product 1 w...

Embodiment 3

[0031] Compound (2) Preparation of 2-ferrocenyl-6-phenylquinoline: under the protection of high-purity nitrogen, add 1.0mmol acetylferrocene and 1.0mmol 4-bromo-o-hydroxymethyl to a 10ml Schlek reaction tube Aniline, 1.0mmol phenylboronic acid, 0.01mmol [Ir(cod)Cl] 2 , 0.01mmol palladium acetate, 0.05mmol triphenylphosphine, 1.0mmol potassium hydroxide and 5ml dioxane, replace the reaction tube with nitrogen for 3 times, then heat to 110°C with an oil bath under magnetic stirring, and reflux for 48 hours .

[0032] The oil bath was removed, and the water bath was lowered to room temperature; 3ml of water was added to the reaction solution, extracted three times with 5ml of dichloromethane, the organic phases were combined and washed with anhydrous MgSO 4 Dry for 30 minutes, filter, and the filtrate is concentrated by a rotary evaporator. The concentrated residue is separated by silica gel column chromatography using dichloromethane as a developing solvent to obtain pure produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com